Flexible stretchable and washable conductive connecting piece

A technology of conductive connections and connectors, which is applied in the field of flexible, stretchable and washable conductive connectors, can solve the problems that limit the development of wearable smart clothing, cannot be done, and poor flexibility, etc., and achieve stable and reliable electrical signal transmission. Little change and excellent fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the present invention more comprehensible, preferred embodiments are described in detail as follows.

[0029] This embodiment provides a flexible, stretchable, and washable conductive connector, which can be made into a flexible, stretchable, and washable conductive connector through material selection, structural design, and composite effects, which can be used in smart clothing instead of metal wires and printed circuits. and smart wearable devices.

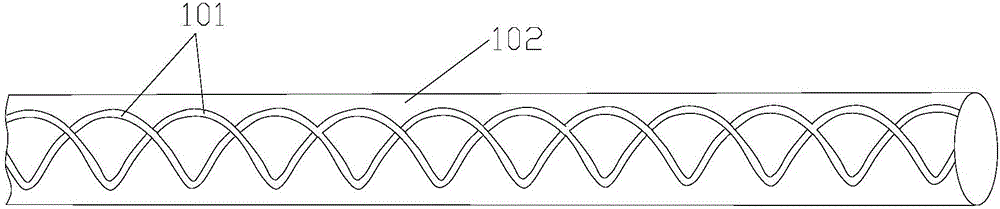

[0030] figure 1 Schematic diagram of the structure of a columnar conductive connector made of double-helix arranged conductive materials sealed in an elastic matrix through composite processing. The conductive material 101 is arranged in a double helix, and the elastic matrix 102 adopts a columnar shape and is wrapped around the conductive material 101 .

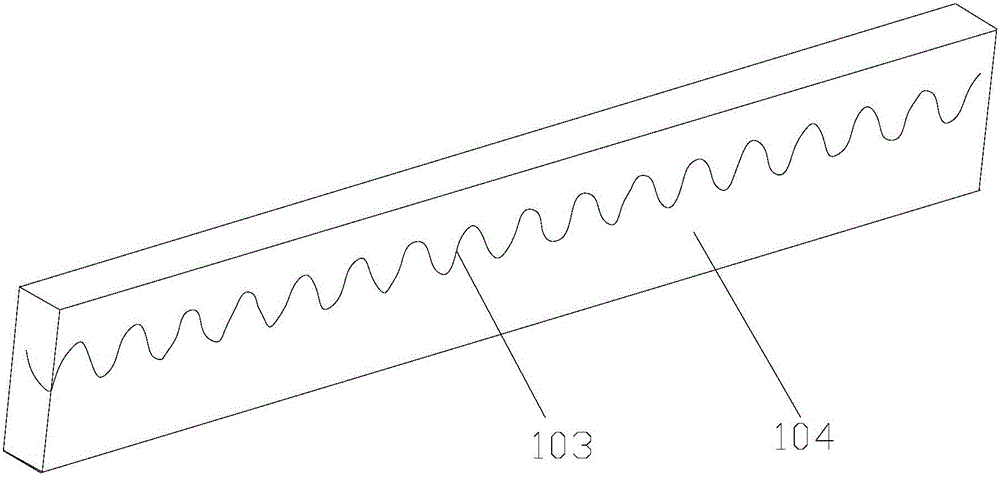

[0031] figure 2 It is a structural schematic diagram of a film-shaped conductive connector made by sealing conductive material in the form of wavy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com