Deicing mechanism on single high voltage power line

A high-voltage line and single-root technology, applied in the field of deicing mechanism, can solve the problems of ice melting, low popularity of robots, and high technical level of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

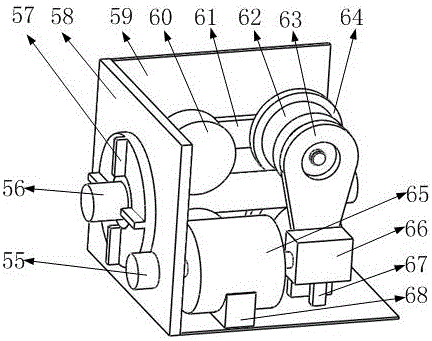

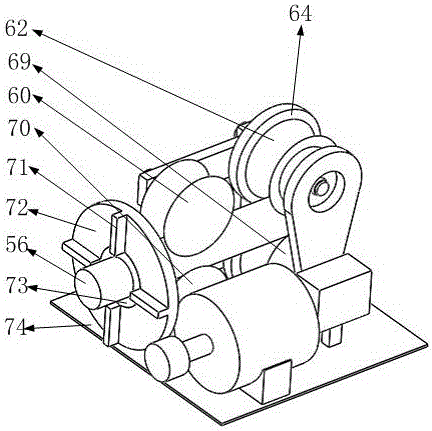

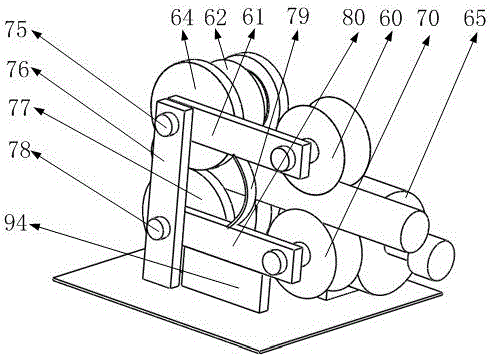

[0027] Such as figure 1 , 2 As shown, it includes deicing gear 55, high voltage electric wire 56, deicing piece 57, front plate 58, side plate 59, floating sheave 60, floating rod 61, active flexible sheave 62, baffle plate 63, first movable tooth 64. Motor 65, gear box 66, gear box support 67, motor support 68, rotating sheave 69, lower floating sheave 70, base 74, first movable tooth rotating shaft 75, rotating shaft supporting plate 76, second movable tooth 77, the first Two moving gear shafts 78, floating leaf springs 79, lower floating rods 80, deicing parts mounting holes 81, drive shaft reset springs 83, sliding grooves 84, sliding keys 85, first support 86 of the sheave, second support 87 of the sheave, Sheave shaft sleeve 88, sliding transmission shaft 89, first universal joint 90, space transmission shaft 91, second universal joint 92, flexible sheave rotating shaft 93, wherein as figure 1 As shown, the two side plates 59 are symmetrically installed on the base 74,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com