Labelling machine

A labeling machine and labeling technology, applied in the directions of labeling, labeling machines, labels, etc., can solve the problems of reducing production, taking too long, reducing customer production capacity, etc., and achieving high productivity and increasing productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

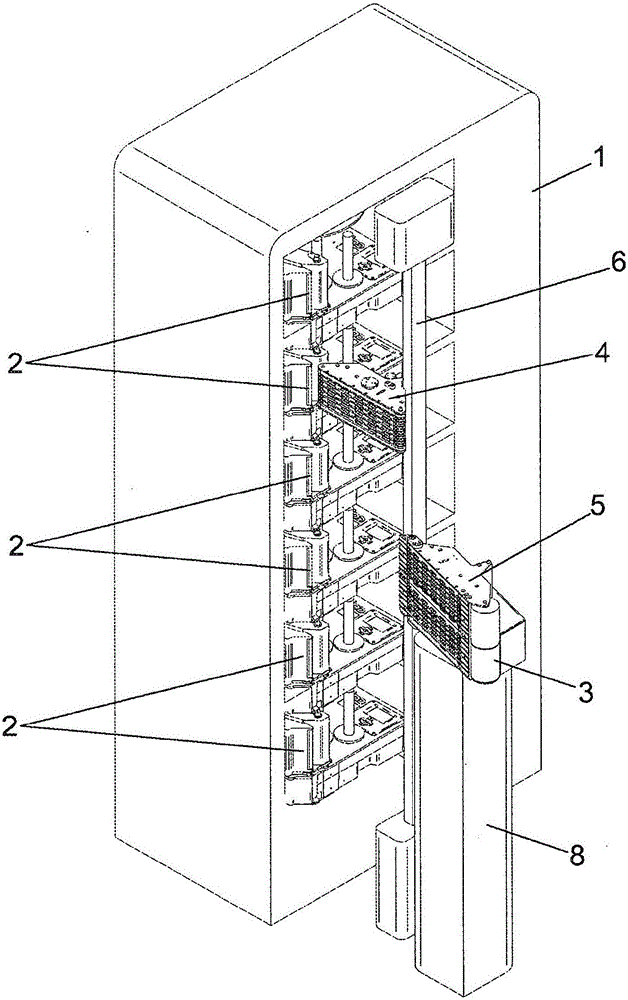

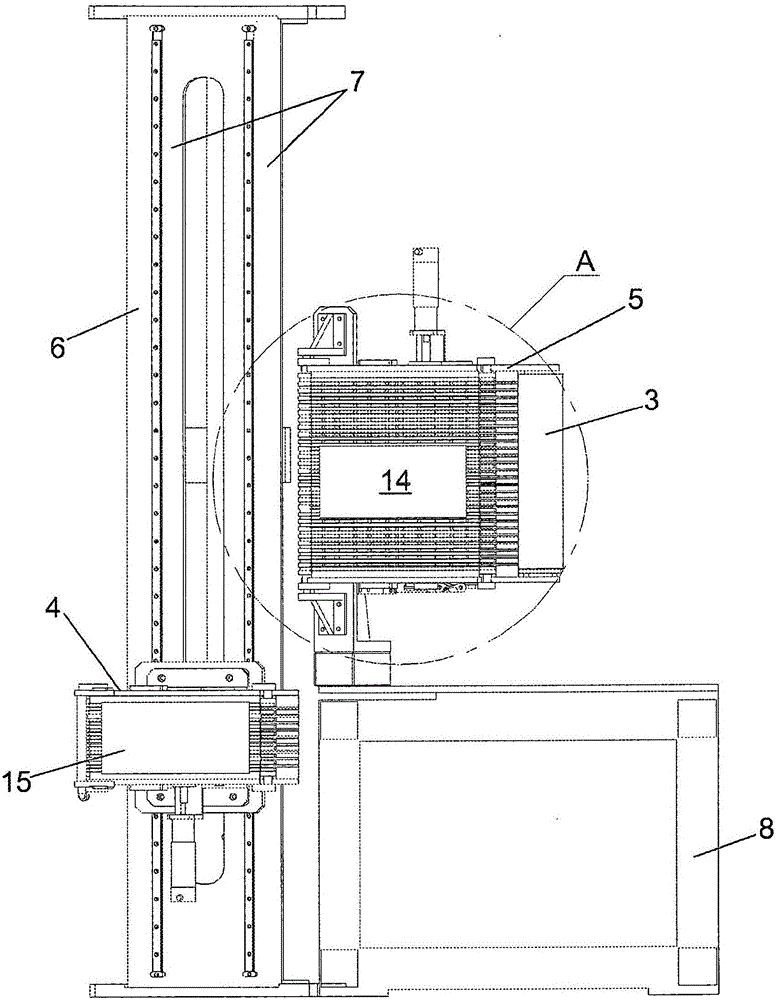

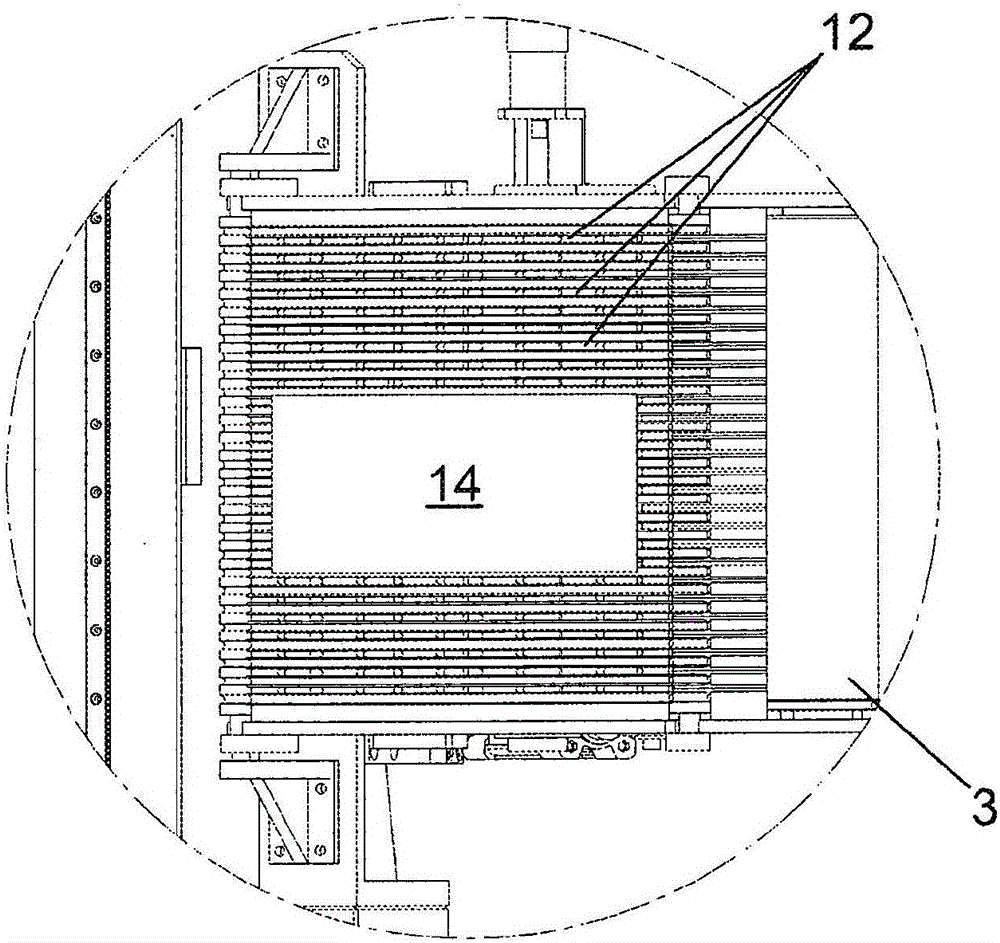

[0029] figure 1 A labeling machine is shown comprising a housing 1 in which a series of label dispensers 2 are housed, arranged in a row and positioned one above the other in different Level, these label dispensers are constructed in a known manner.

[0030] figure 1 The machine shown in also comprises label application means 3, which may be of the roller, brush or blade type, among others. The label applying device 3 is located at a distance from the cylindrical body of the label dispenser 2 .

[0031] The label transport means are located between the column of label dispensers 2 and the label application device 3 . They are responsible for transporting the labels supplied by a label dispenser 2 to the label application device 3 .

[0032] The mentioned transport means comprise: a first transport module 4 movable vertically between positions coinciding with those occupied by the label dispenser 2; and a second transport module 5 which The height of the two transport modu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap