Curable organopolysiloxane composition and release film for use with dielectric ceramic layer-forming material using same

A technology of organopolysiloxane and polysiloxane, which is applied in the direction of synthetic resin layered products, coatings, layered products, etc., to achieve the effect of excellent ease and releasability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

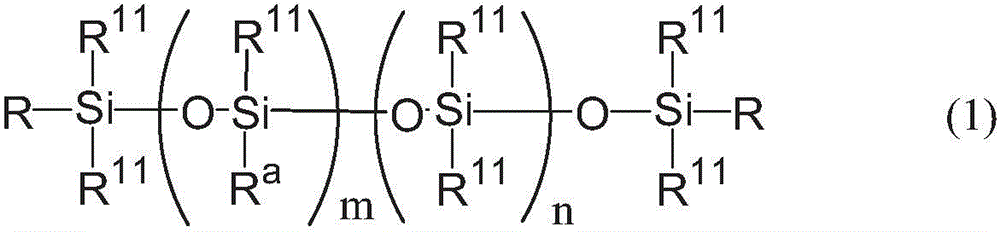

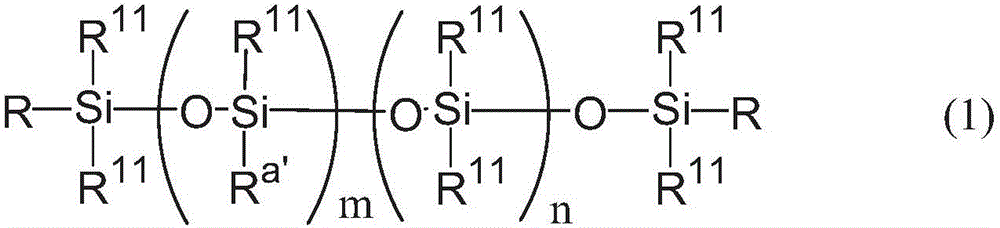

Method used

Image

Examples

example 1

[0134] Working Example 1 - Composition 1

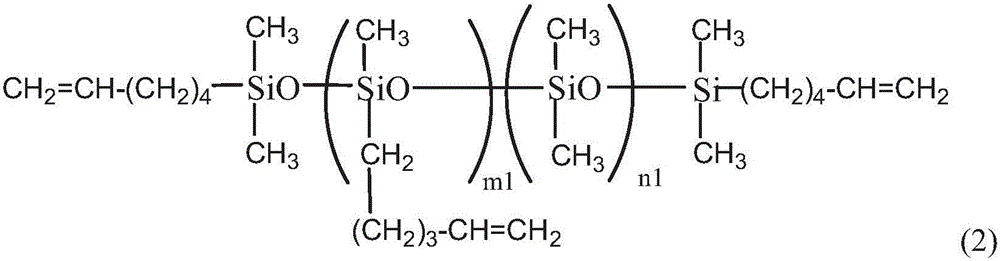

[0135] (A) 30.0 parts of polydimethylsiloxane (plasticity: 1.15; hexenyl group vinyl (CH2=CH-) part content) having hexenyl groups at both terminals and on the side chain : 0.80 mass %), (B) 1.5 parts of dimethylsiloxane (plasticity: 1.20; vinyl group content: 0.02 mass %), (C) 1.3 parts of 25 mPa Dimethylmethylhydrogenpolysiloxane of s viscosity (such that the SiH / Vi ratio of the composition is overall 1.5), (E) 66.2 parts of toluene, and (F) 1.0 parts of 3-methyl-1 - Butyn-3-ol was mixed to a uniform consistency to obtain a solvent-containing curable organopolysiloxane composition (Composition 1). Next, the obtained organopolysiloxane composition was diluted with (E) a 50:50% by weight mixture of toluene and hexane to adjust the solid concentration to 3.0% by weight, and (D) chloroplatinic acid / 1, 3-divinyl-1,1,3,3-tetramethyldisiloxane complex (metal platinum content: 0.6% by mass) was added in a certain amount (the amount was ...

example 2

[0136] Working Example 2 - Composition 2

[0137] Composition 2 was obtained in a similar manner to Working Example 1, except that the amount of component (B) used in Working Example 1 was changed to 0.4 parts. Using this composition, the ease of applying the ceramic binder resin to the cured layer and the peeling force required to peel the ceramic binder resin from the cured layer were measured. The results are shown in Table 1.

example 3

[0138] Working Example 3 - Composition 3

[0139] Composition 3 was obtained in a similar manner to Working Example 1, except that the amount of component (B) used in Working Example 1 was changed to 3.0 parts. Using this composition, the ease of applying the ceramic binder resin to the cured layer and the peeling force required to peel the ceramic binder resin from the cured layer were measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com