Intermediate transfer belt, image forming apparatus, and method for producing intermediate transfer belt

An intermediate transfer belt and image technology, applied to the electrical recording process using charge graphics, equipment and instruments using the electrical recording process using charge graphics, etc., can solve the problems of insufficient utilization, reduced transfer pressure, and reduced durability, etc. problem, to achieve the effect of excellent toner releasability, excellent filming resistance, and excellent cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

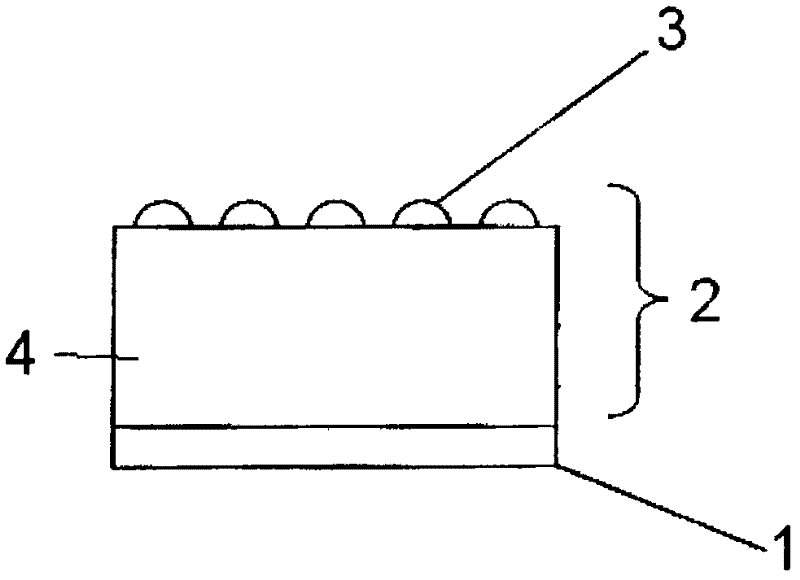

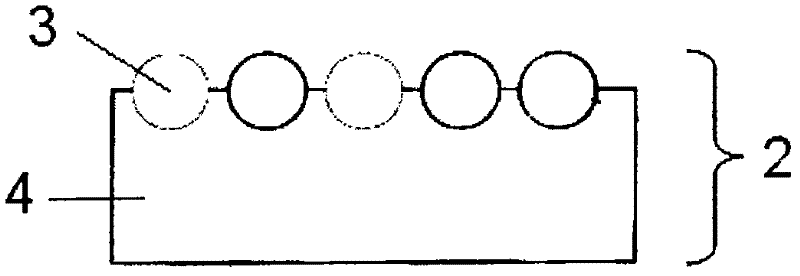

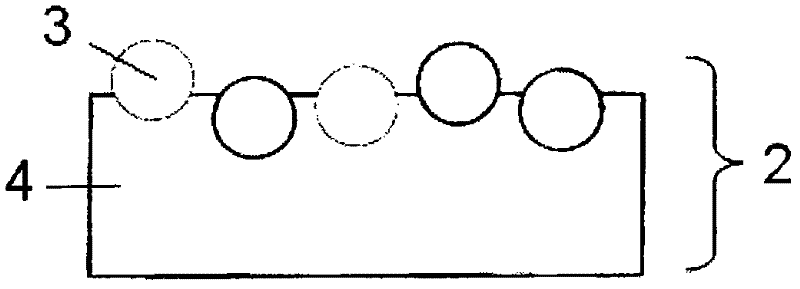

Image

Examples

Embodiment 1

[0150] A coating liquid for the base layer was prepared as described below, and the base layer for a seamless belt was produced using the coating liquid.

[0151]

[0152] First, a dispersion previously prepared by dispersing carbon black (SPECIAL BLACK 4; from Evonik Degussa) in N-methyl-2-pyrrolidone using a bead mill was mixed with a polyimide resin mainly composed of a polyimide resin precursor. Amine resin liquid (U-VARNISH A; from Ube Industries, Ltd.) was mixed so that the content of carbon black was 17% by mass of the solid content of polyamic acid, and then sufficiently stirred to prepare a coating liquid for the base layer a.

[0153]

[0154] Next, using a metal cylindrical support (outer diameter: 340 mm, length: 360 mm) as a mold, the outer surface of which has been roughened by blasting, the Image 6 Install the cylindrical support in the roll coater shown in .

[0155] Then, the coating liquid A of the base layer was flowed into the paint pan, and pulled u...

Embodiment 2

[0184] Except that the spherical resin particles were changed to silicone resin particles (KMP 701 (volume average particle diameter: 3.5 μm, monodisperse particles); from Shin-Etsu Chemical Co., Ltd.), an intermediate was obtained in the same manner as in Example 1. Transfer belt B.

Embodiment 3

[0186] An intermediate transfer belt C was obtained in the same manner as in Example 1 except that the spherical resin particles were changed to silicone resin particles (TOSPEARL 120 (volume average particle diameter: 2.0 μm; monodisperse particles); from MomentivePerformance Materials Inc.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com