Simple-structured cylindrical cam horizontal pounding machine

A cylindrical cam technology with a simple structure is applied in the field of processing machinery to achieve the effects of improving production efficiency, simple transmission mode and high mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

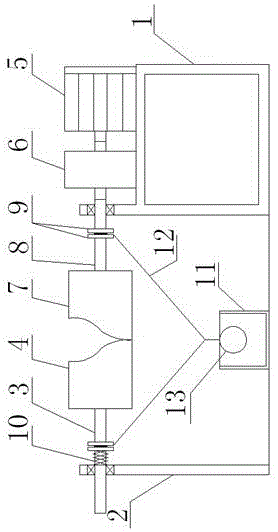

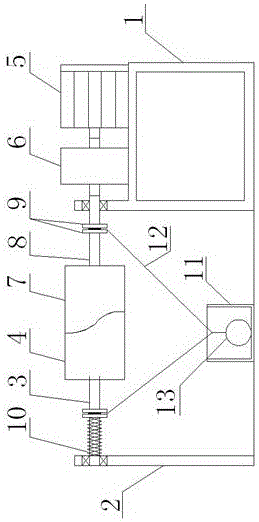

[0021] Such as figure 1 , figure 2 As shown, a cylindrical cam horizontal pounding machine with a simple structure includes a frame 1, a bracket 2, a driven shaft 3, a driving shaft 8, a motor 5 mounted on the frame 1 through bolts, and one end of the driven shaft 3 slides Connected to the bracket 2, it can do linear reciprocating motion on the bracket 2, the other end of the driven shaft 3 is connected with the passive cylindrical cam 4, the driving shaft 8 is connected to the frame 1 through the bearing rotation, between the driving shaft 8 and the motor 5 A reduction box 6 is connected, the other end of the driving shaft 8 is connected with a driving cylindrical cam 7, two baffle plates 9 are welded at intervals on the driving shaft 8 and the driven shaft 3, and the driving shaft 8 and the driven shaft 3 are bolted with cables 12 , wherein the wires 12 are respectively bolted between the intervals between the two baffles 9 provided on the driving shaft 8 and the intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com