Oil spraying type multifunctional surface treatment equipment

A surface treatment, oil-spraying technology, applied in the direction of surface pretreatment, device for coating liquid on the surface, spray device, etc., can solve the problems of ineffective absorption of dust, low product qualification rate, ineffective treatment of paint mist, etc. Achieve the effect of saving equipment investment and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

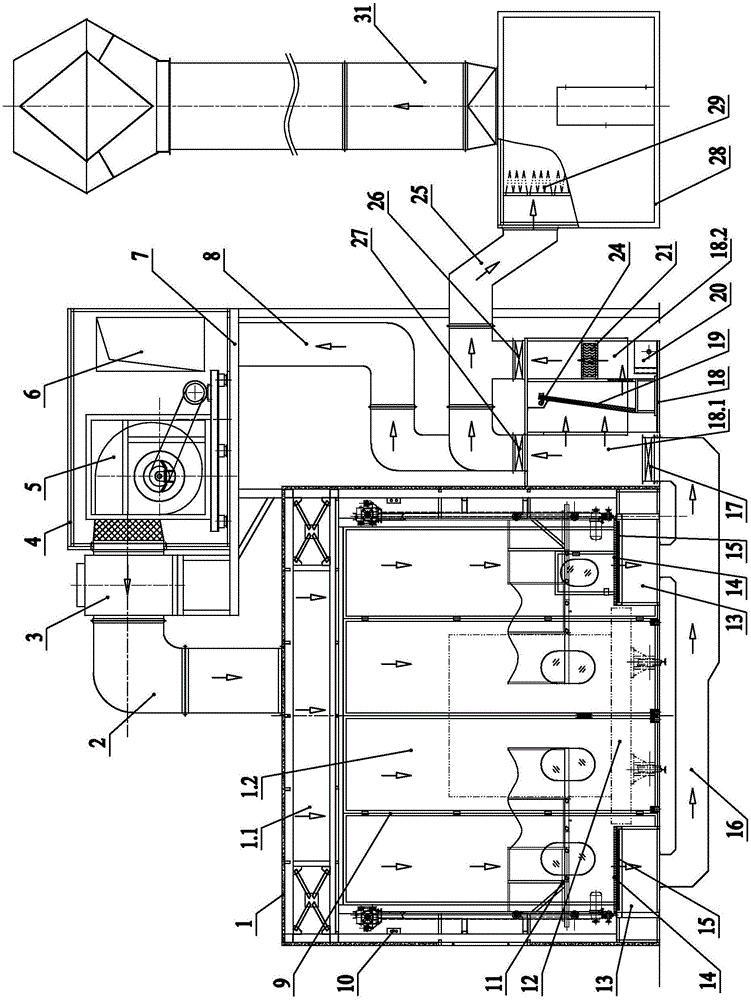

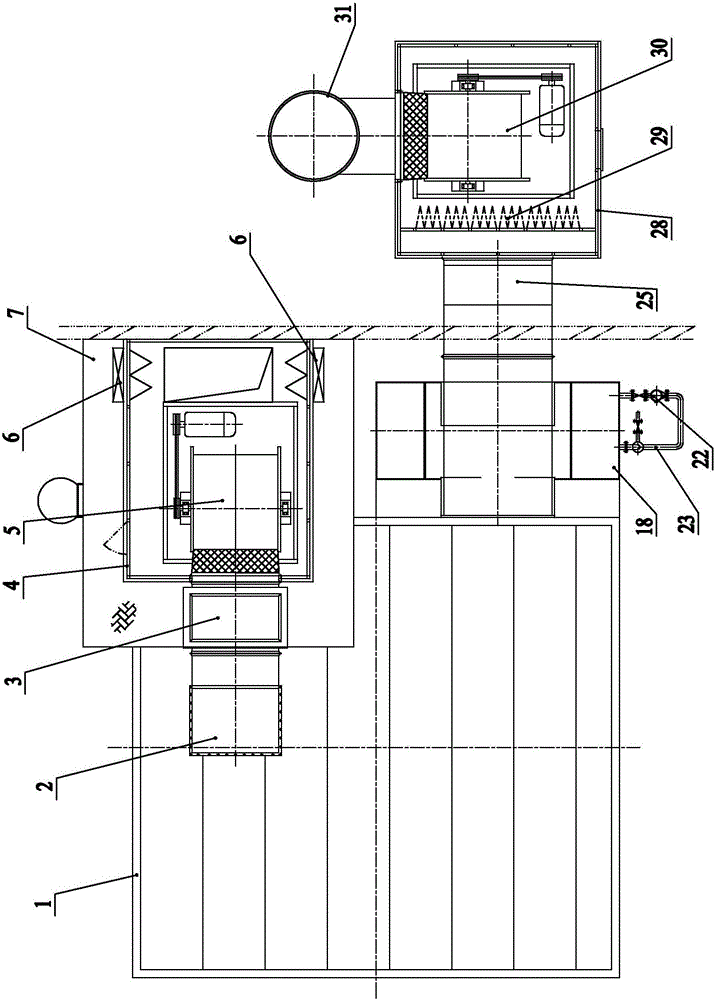

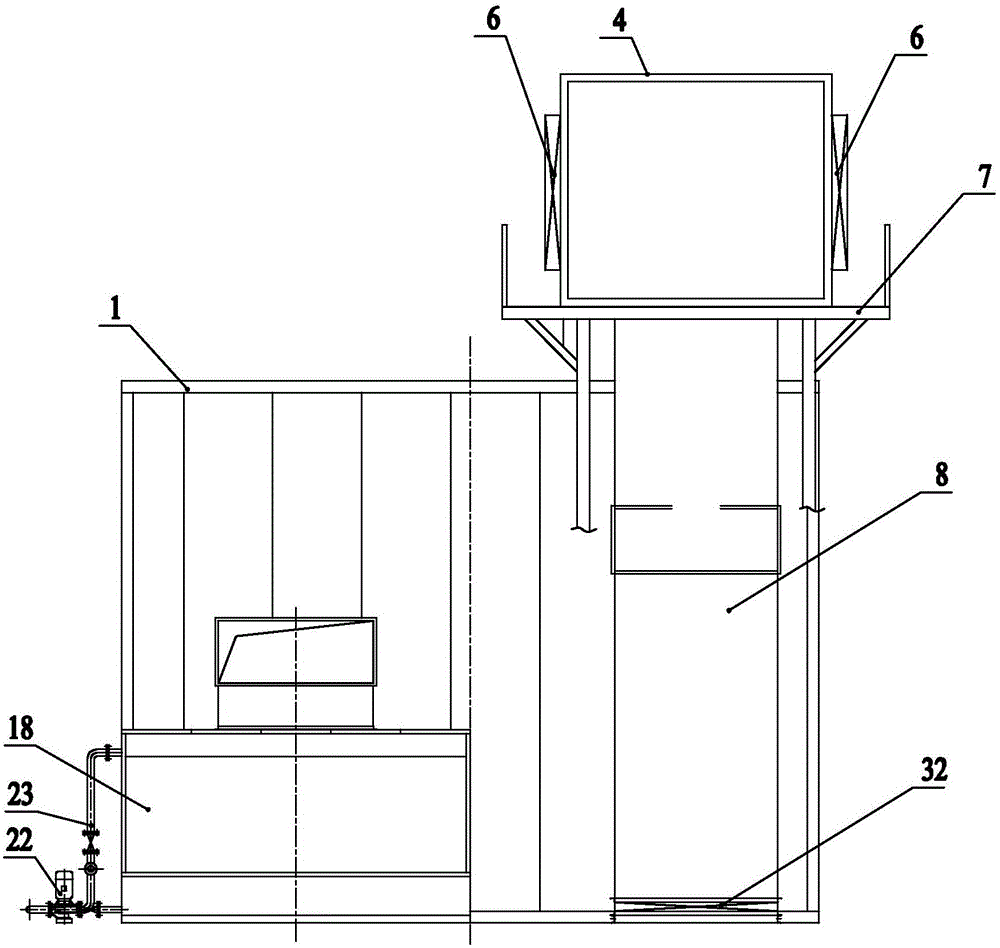

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0023] As shown in the figure: the oil shower multifunctional surface treatment equipment in the embodiment is mainly composed of a chamber body 1, a fresh air circulation air supply pipe 2, an electric heating hot air generator 3, a fan chamber body 4, a blower fan 5, and a fresh air electric fan Valve 6, fan platform 7, hot air circulation return pipe 8, gate 9, lighting light box 10, three-dimensional lifting operation table 11, electric flat car 12, induced air chamber 13, steel grille 14, paint mist filter cotton 15, induced air Pipe 16, oil spray paint mist purification air intake electric air valve 17, clean room body 18, oil curtain plate 19, oil storage tank 20, oil gas separator 21, circulating oil pump 22, pipeline 23, oil spray pipe 24, exhaust pipe 25 , exhaust air electric air valve 26 after oil shower, cleaning exhaust air outlet through cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com