A food waste slag liquid separator

A kitchen waste and separator technology, applied in liquid separation, filtration separation, separation methods, etc., can solve the problems of slow filtration, inability to quickly discharge kitchen waste solids, and non-compliance with environmental protection regulations, and achieve separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

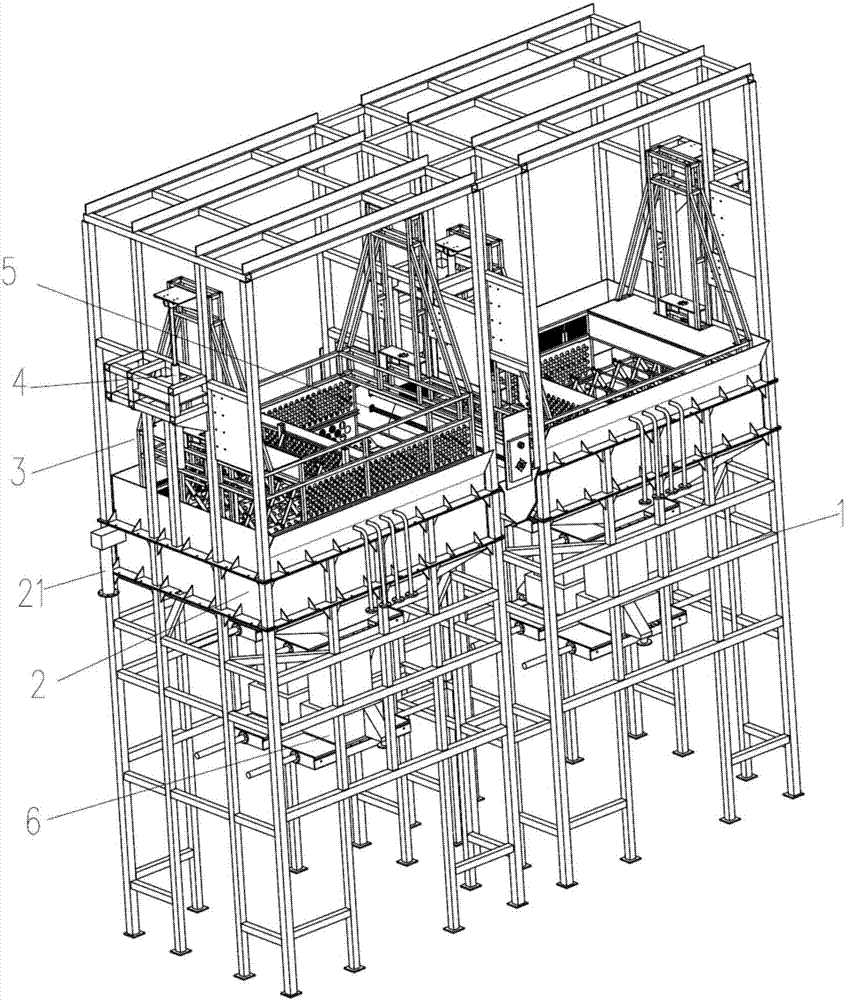

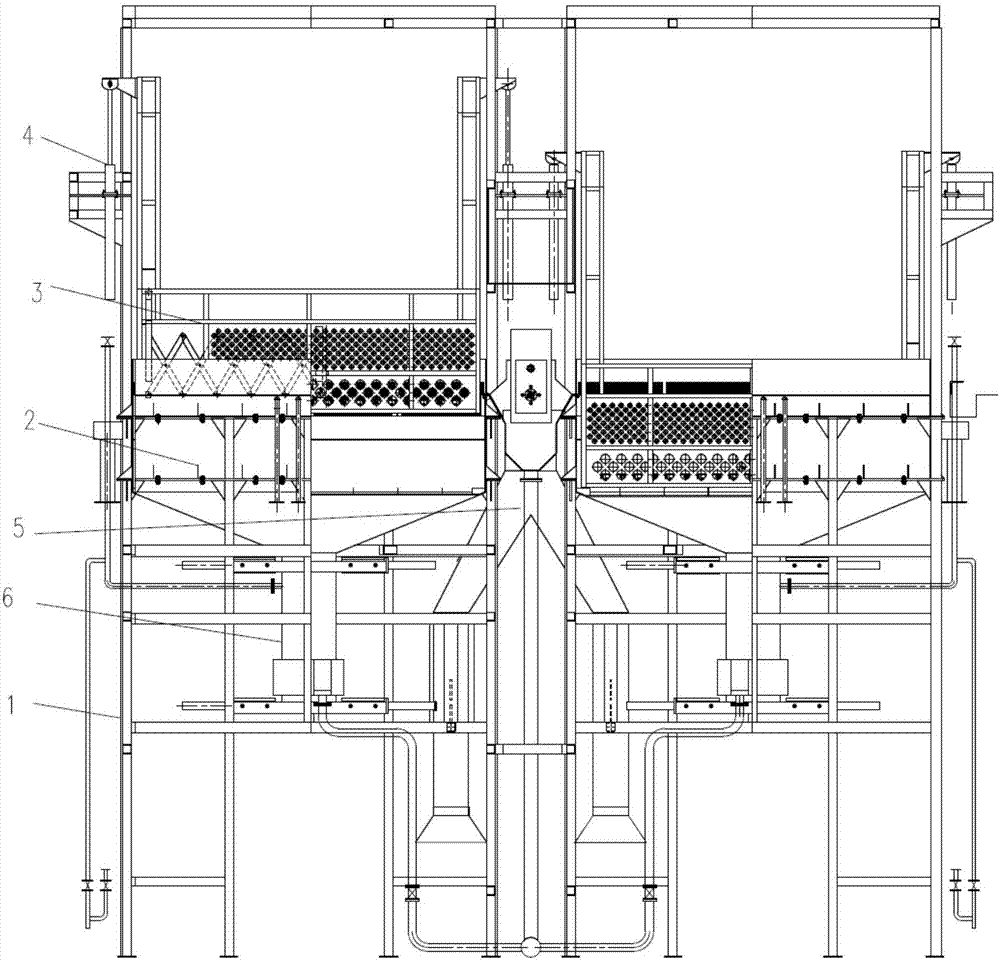

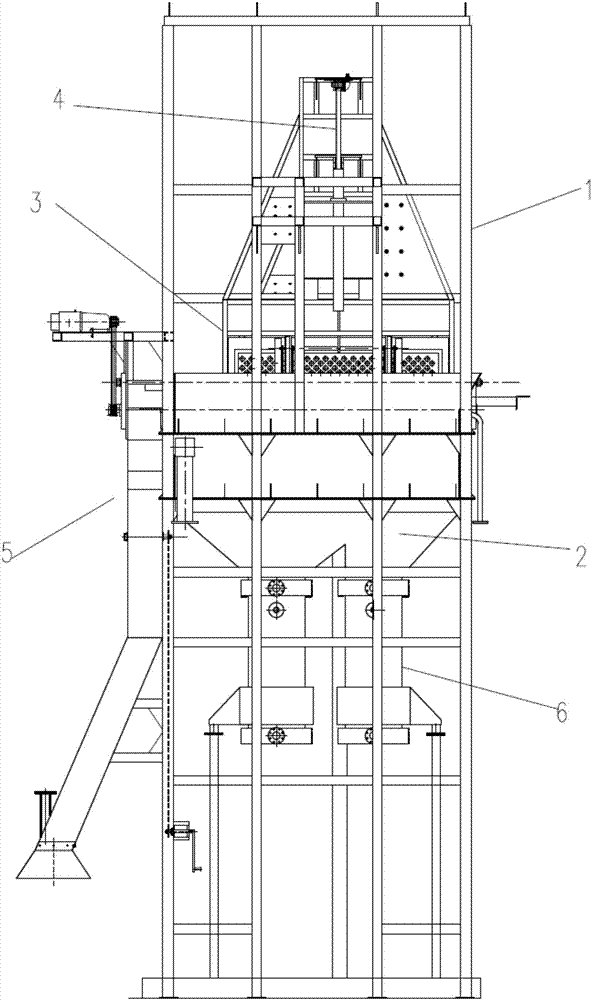

[0031] Such as Figure 1 to Figure 3 As shown, the present invention proposes a kitchen waste slag-liquid separator, comprising: a frame 1; a steel pool body 2 installed on the frame 1 to store warm water; a grate device is arranged above the steel pool body 2 3, to store food waste solids; on the frame 1, a lifting mechanism 4 is arranged, and the lifting mechanism 4 is connected with the trough device 3, so that the trough device 3 can be immersed in or out of warm water back and forth; on the frame 1 A draining and scraping tank 5 located next to the draining and scraping tank 3 is provided. When the lifting mechanism 4 lifts the draining and scraping tank 3 to a position flush with the draining and scraping tank 5, the draining and scraping tank 5 outputs meals to the draining and scraping tank 5. Kitchen waste solids, draining and scraping slag tank 5 is used to discharge the food waste solids into the transport barrel; a slag-liquid separator 6 is arranged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com