Spring-hook composite triple parting pin-point gate injection mold

The technology of a spring hook and an injection mold is applied in the field of plastic injection molding to achieve the effects of convenient debugging and maintenance, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

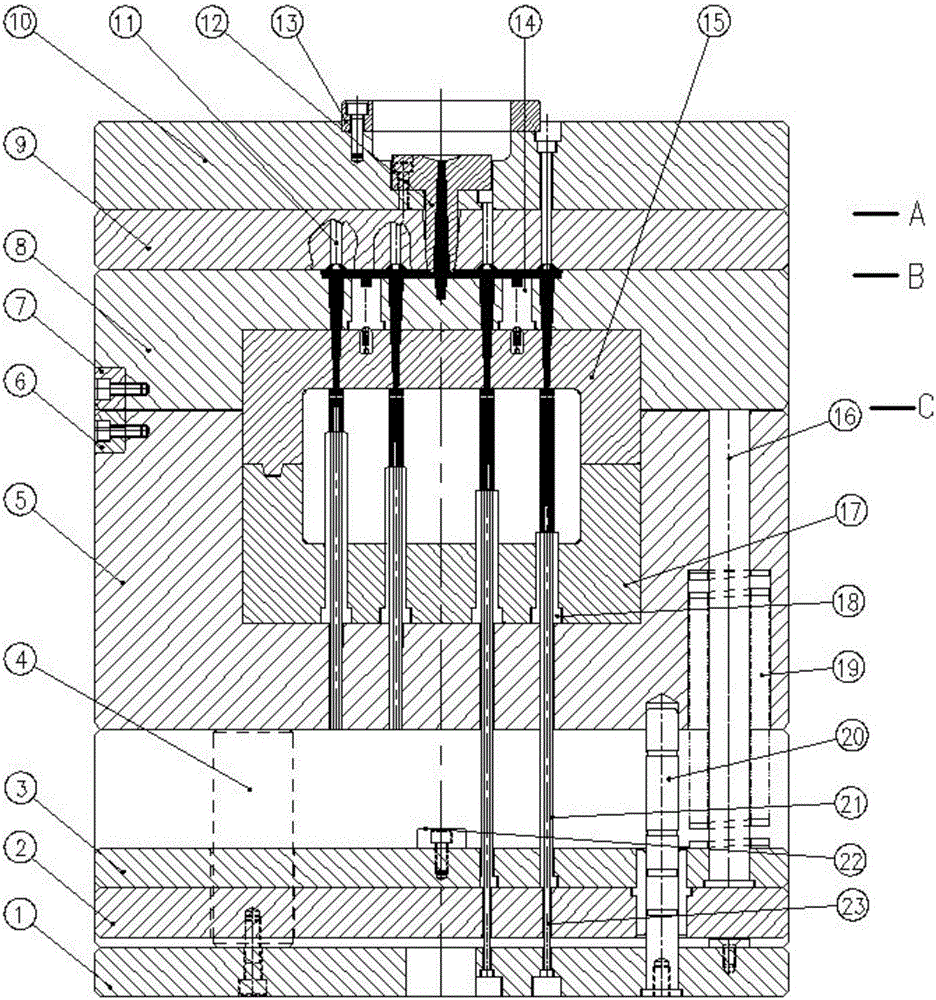

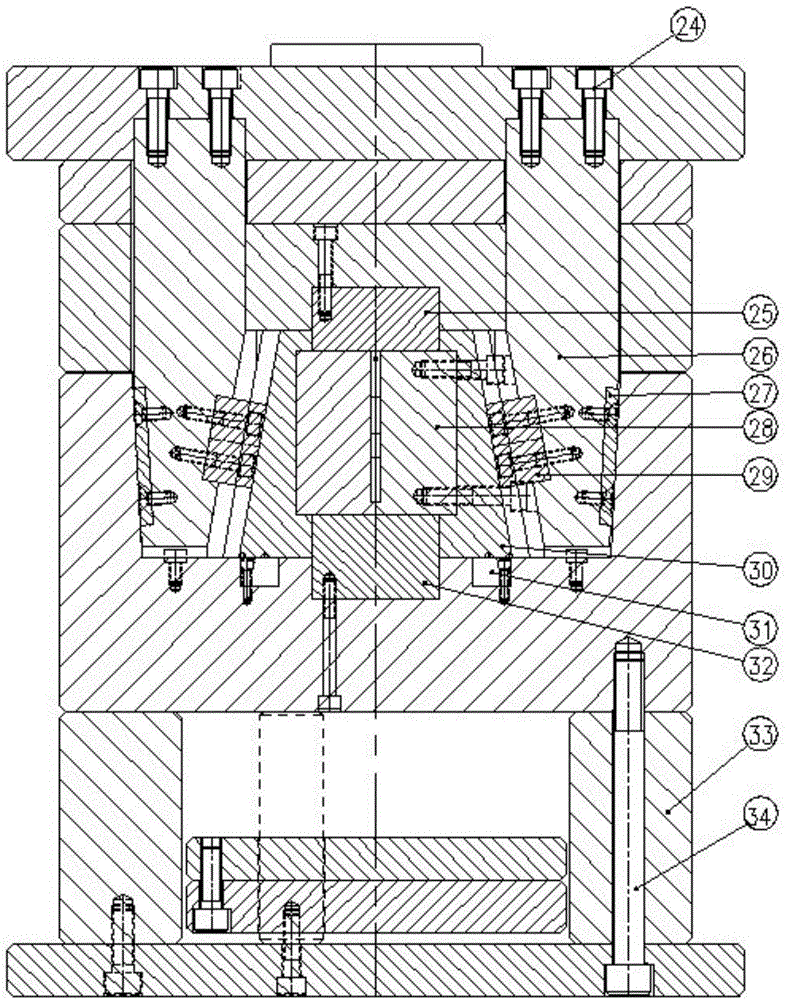

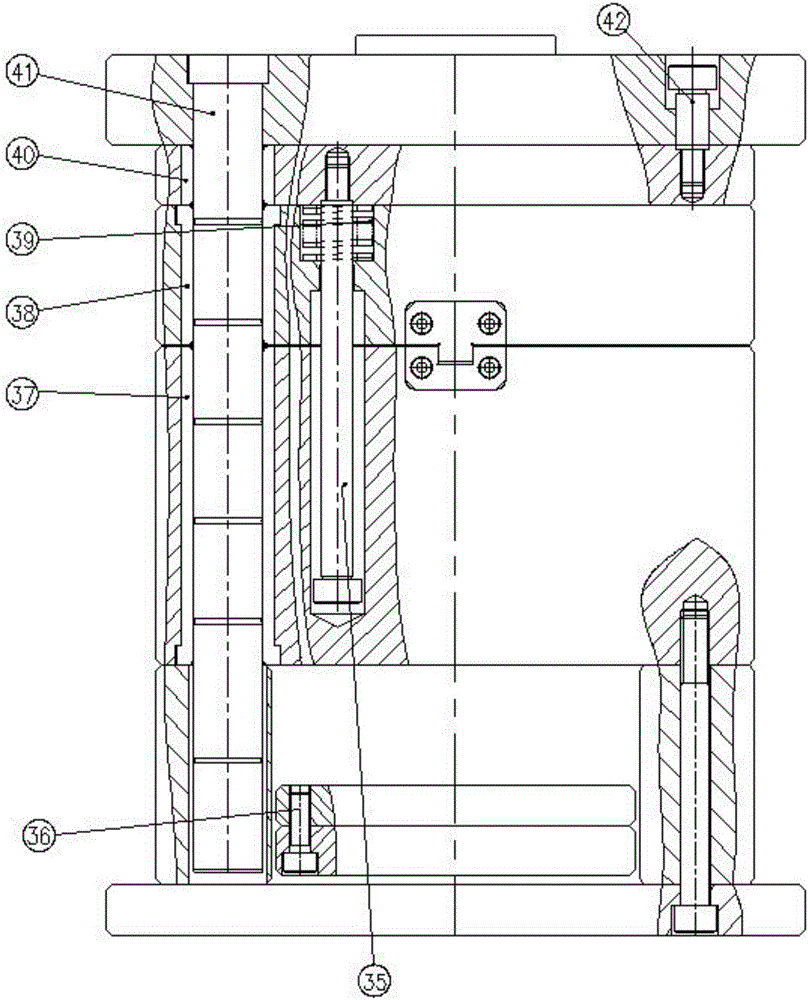

[0024] Examples. The present invention provides a method and injection mold for a three-time split-mold pull-off point gate with a spring hook compound, see Figure 1 to Figure 12 , Including the movable mold bottom plate 1, the ejector plate 2, the top rod fixed plate 3, the support column 4, the backing plate 5, the guide block one 6, the guide block two 7, the fixed template 8, the stripping board 9, the fixed mold bottom plate 10, Pull rod 11, sprue bushing 12, positioning ring 13, insert 14, cavity insert 15, reset rod 16, movable mold insert 17, core 18, spring 19, guide post 20, Top tube 21, stop nail 22, middle core 23, screw one 24, insert two 25, oblique pressure block 26, wear block 27, side core 28, T-shaped slider 29, side slider 30, spacer block 31. Movable mold insert 32, mold foot 33, screw two 34, limit rod 35, screw three 36, guide sleeve one 37, guide sleeve two 38, spring two 39, guide sleeve three 40, guide post two 41, limit The positioning screw 42, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com