A method for forming a high-temperature-resistant composite cabin section with an end frame

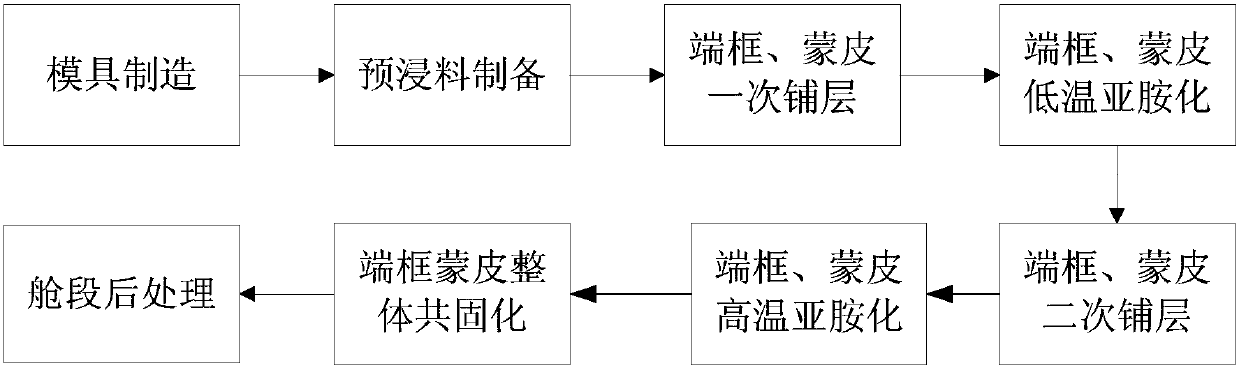

A technology of composite materials and forming methods, which is applied in the field of forming high-temperature-resistant composite material compartments with end frames, can solve the problems of difficult forming of components, reduce the thickness of heat-resistant layers, and high volatile content, and achieve high-temperature bearing capacity and Effects of reliability, increased payload, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Both the end frame and the skin material are laminated with MT300 / 904 unidirectional tape and fabric prepreg. The prepreg is prepared by solution method. The unidirectional tape prepreg has a glue content of 47±3% and an area density of 165± 5g / m 2 , thickness 0.15mm; MT300 / 904 fabric prepreg, glue content 47±3%, areal density 275±5g / m 2 , thickness 0.27mm.

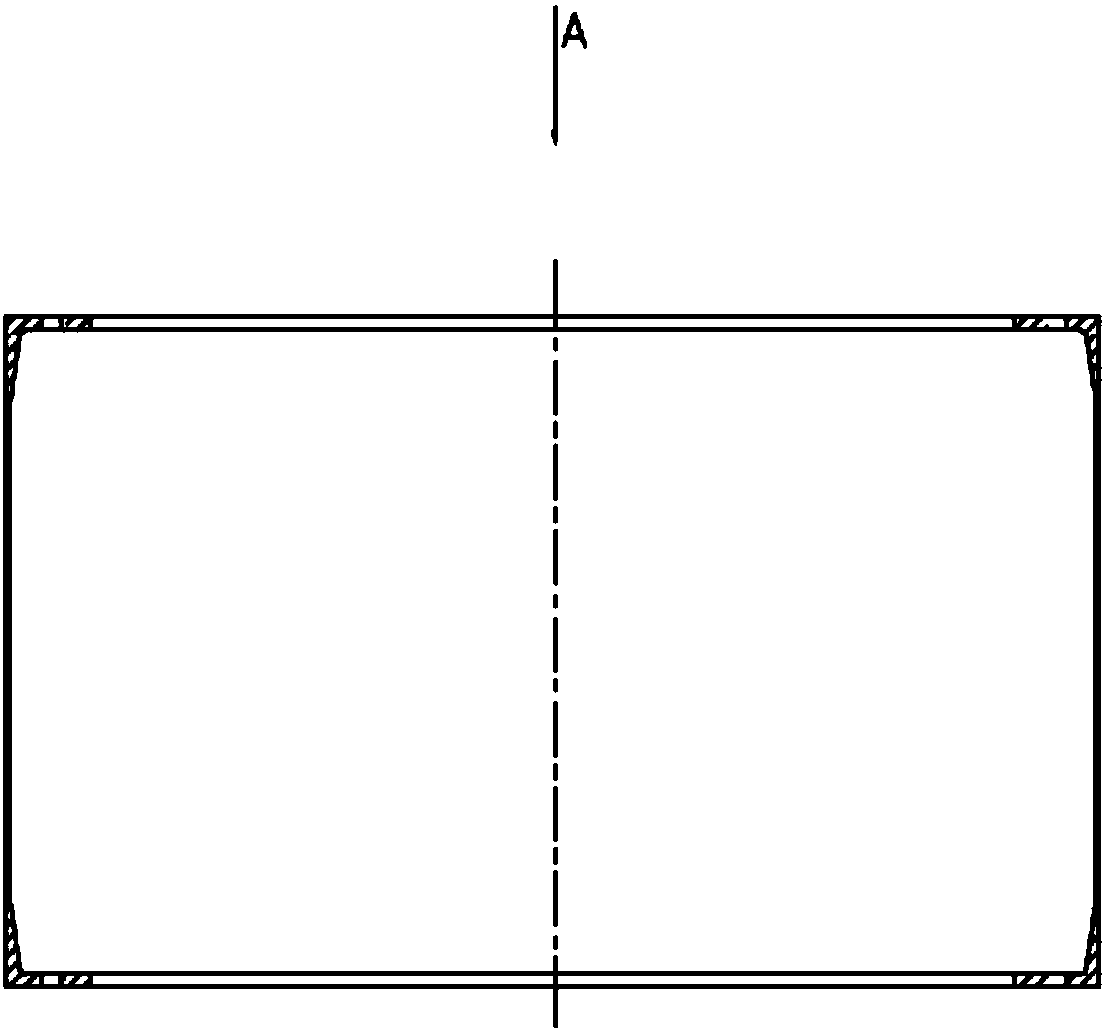

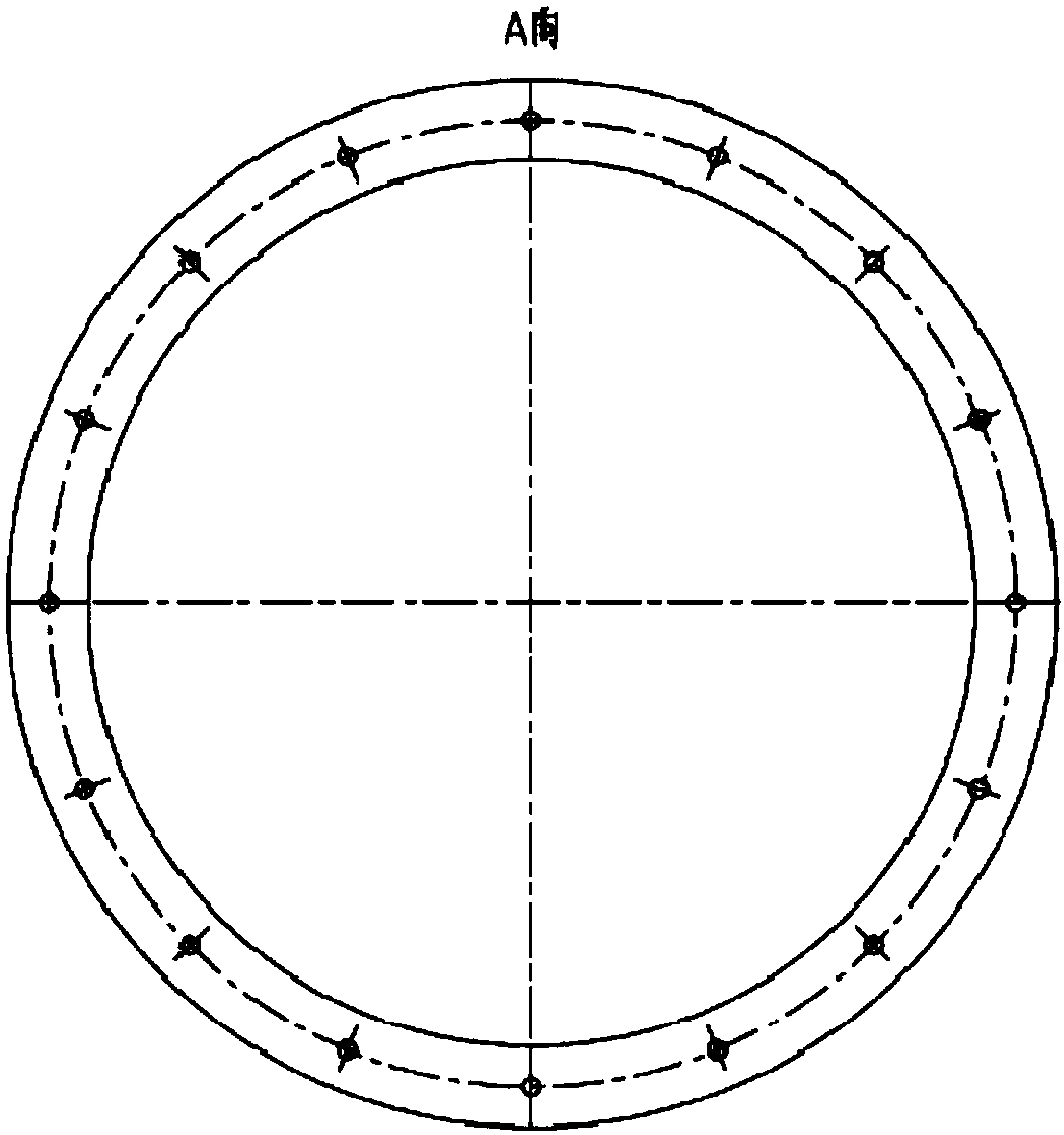

[0051] After the automatic blanking machine is used for blanking according to the layup and size requirements, the multi-layer end frame and skin prepreg are laid layer by layer on the end frame imidization mold and the cabin integral molding mold according to the designed layup angle , where the end frame layer is [+45 / -45 / carbon cloth / 0 / carbon cloth / 0 2 / carbon cloth / 0]2s, the skin layer is [+45 / -45 / carbon cloth / 0 / carbon cloth]s (carbon cloth means fabric prepreg), and the composite material prepreg laminate is prepared, and the After lamination of composite material prepregs, auxiliary materials such as PTFE ...

Embodiment 2

[0054] Both the end frame and the skin material are laminated with MT300 / 904 unidirectional tape and fabric prepreg. The prepreg is prepared by solution method. The unidirectional tape prepreg has a glue content of 47±3% and an area density of 165± 5g / m 2 , thickness 0.15mm; MT300 / 904 fabric prepreg, glue content 47±3%, areal density 275±5g / m 2 , thickness 0.27mm.

[0055] After the automatic blanking machine is used for blanking according to the layup and size requirements, the multi-layer end frame and skin prepreg are laid layer by layer on the end frame imidization mold and the cabin integral molding mold according to the designed layup angle , where the end frame layer is [+45 / -45 / carbon cloth / 0 / carbon cloth / 0 2 / carbon cloth / 0]2s, the skin layer is [+45 / -45 / carbon cloth / 0 / carbon cloth]s (carbon cloth means fabric prepreg), and the composite material prepreg laminate is prepared, and the After lamination of composite material prepregs, auxiliary materials such as PTFE ...

Embodiment 3

[0058] Both the end frame and the skin material are laminated with MT300 / 904 unidirectional tape and fabric prepreg. The prepreg is prepared by solution method. The unidirectional tape prepreg has a glue content of 47±3% and an area density of 165± 5g / m 2 , thickness 0.15mm; MT300 / 904 fabric prepreg, glue content 47±3%, areal density 275±5g / m 2 , thickness 0.27mm.

[0059] After the automatic blanking machine is used for blanking according to the layup and size requirements, the multi-layer end frame and skin prepreg are laid layer by layer on the end frame imidization mold and the cabin integral molding mold according to the designed layup angle , where the end frame layer is [+45 / -45 / carbon cloth / 0 / carbon cloth / 0 2 / carbon cloth / 0]2s, the skin layer is [+45 / -45 / carbon cloth / 0 / carbon cloth]s (carbon cloth means fabric prepreg), and the composite material prepreg laminate is prepared, and the After lamination of composite material prepregs, auxiliary materials such as PTFE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com