Automatic recycling system for scraps of metal printed decorative panels

A technology of automatic recycling and recycling system, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve problems such as uneconomical environmental protection, and achieve the effect of reducing production cost, improving work efficiency and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

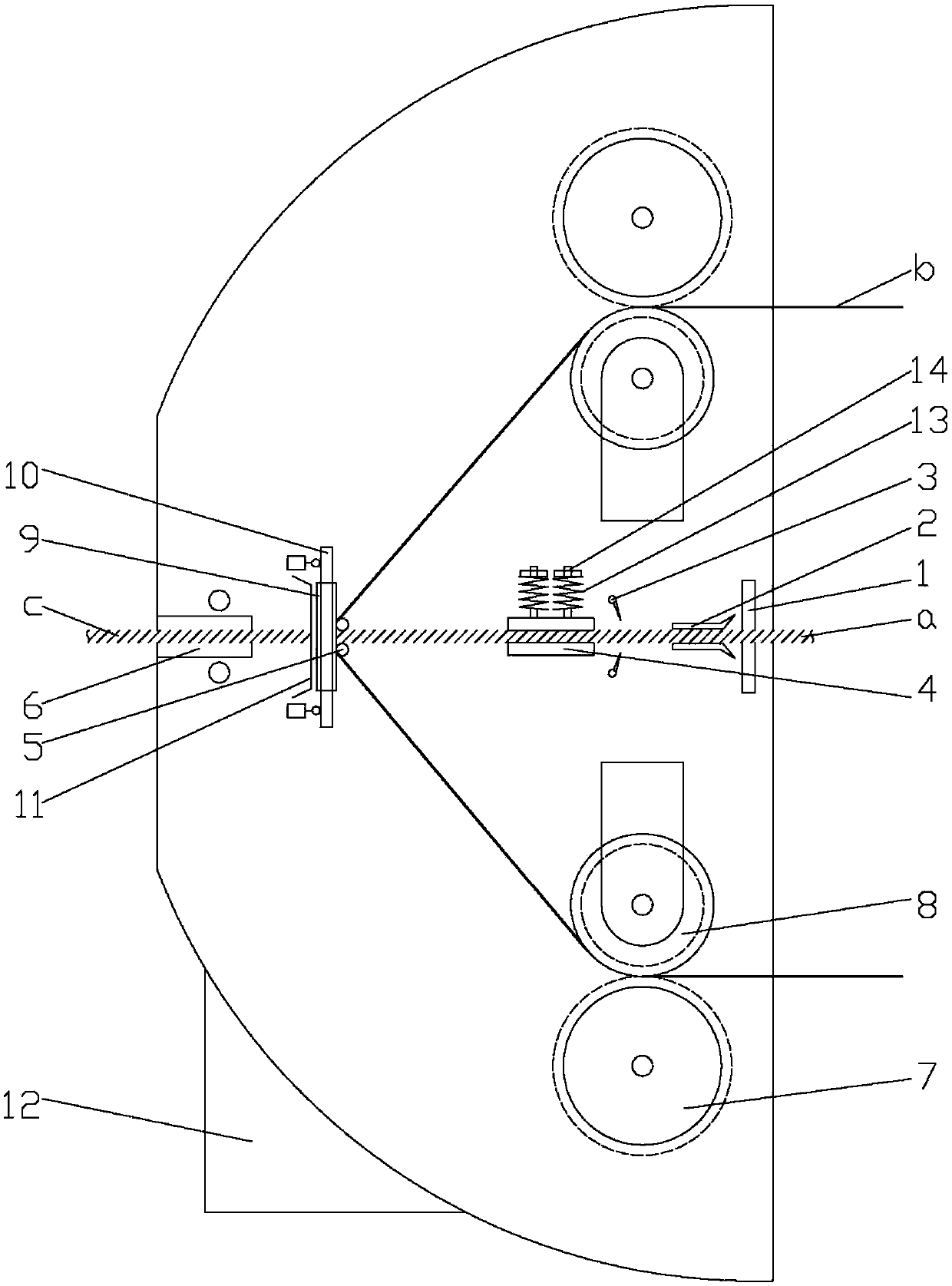

[0013] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0014] see figure 1 , The automatic recycling system for trimmings for metal printing decorative boards, set the direction of the scrap metal printing decorative board a to the front and rear direction, the recycling system has two sides used to recycle the trimmings of the scrap metal printing decorative board a and arranged symmetrically up and down Material recovery device; each edge material recovery device includes roller 1, guide wheel 2, scraper 3, pressing guide wheel 4, separating wheel 5, metal belt traction mechanism and waste core material guide wheel 6; scrap metal printing decorative board a After the guiding action of the two rollers 1 and the two guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com