250 MW supercritical tower-type fan and Pi-type fan milled lignite boiler

A technology of supercritical tower type and fan mill, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of difficult burning of lignite, meet the requirements of energy saving and consumption reduction, and overcome the difficulties of improving efficiency. Effects of market competitiveness and market availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

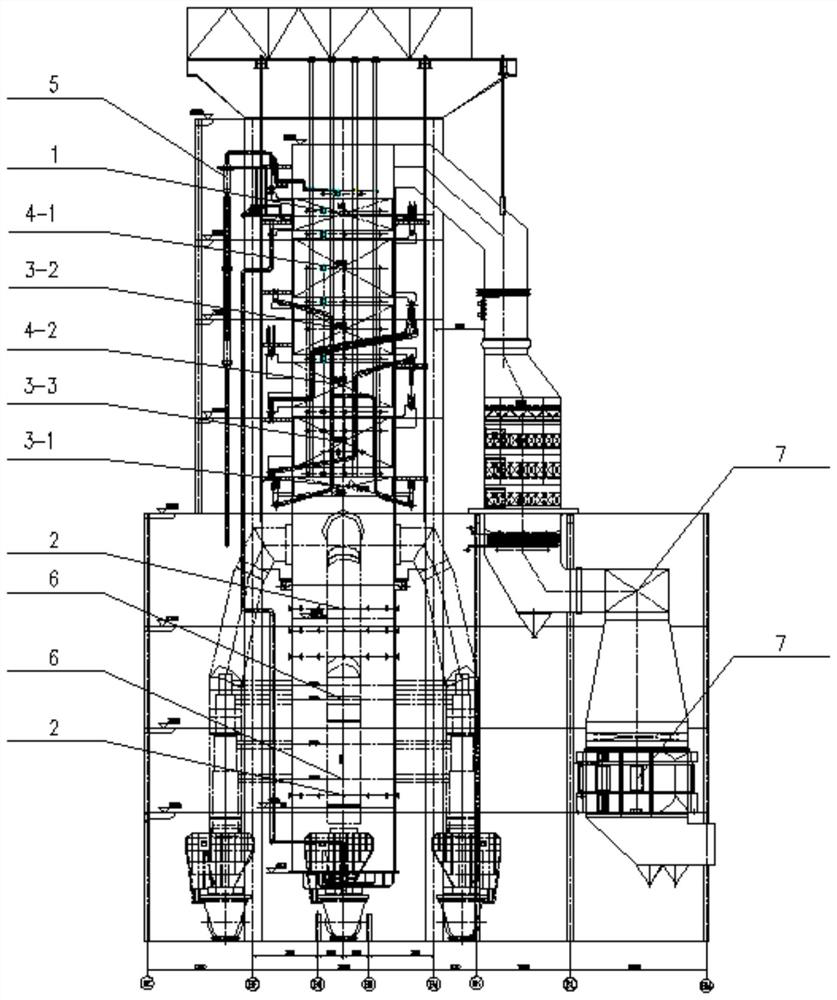

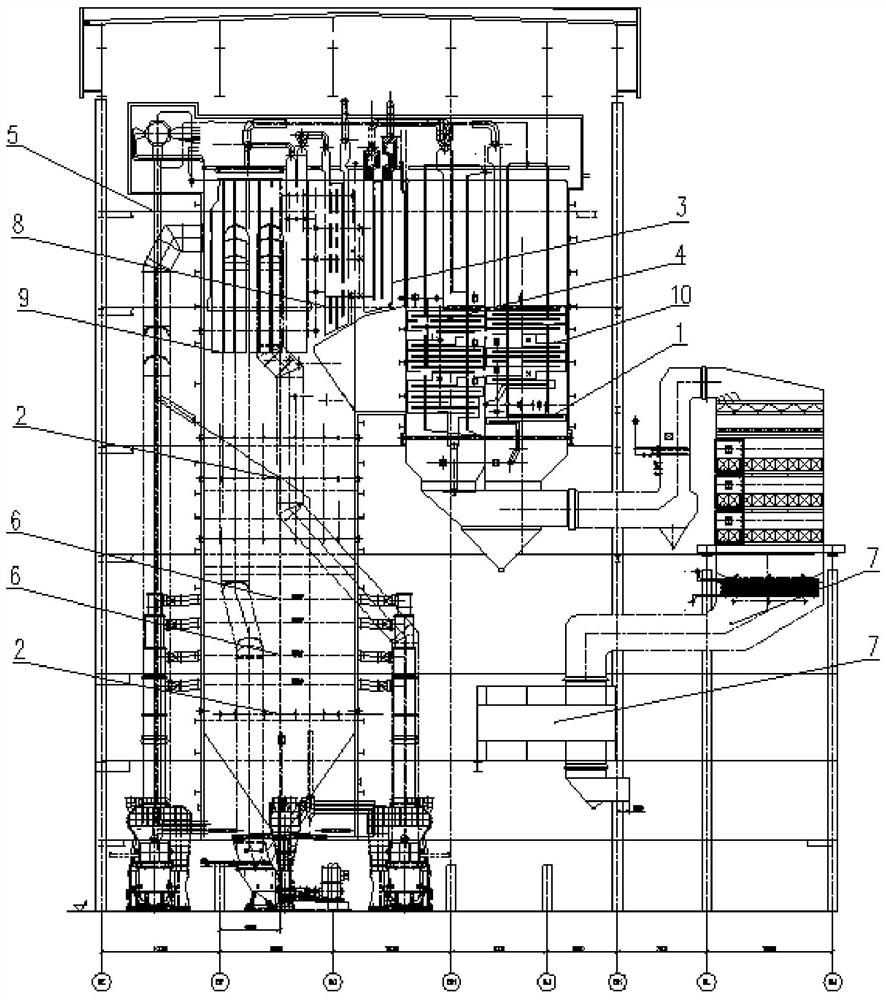

[0023] Specific implementation mode one: combine figure 1 Describe this embodiment, a 250MW supercritical tower fan pulverized lignite boiler described in this embodiment includes an economizer 1, a water wall 2, a superheater system, a reheater system, a starting system 5, a combustion system 6 and The flue air system 7, the economizer 1, the superheater system and the reheater system are all installed on the upper part of the boiler furnace, the water wall 2 and the combustion system 6 are all located at the lower part of the boiler furnace, and the starting system 5 and The water wall 2 is connected to the superheater system, and the flue air system 7 is connected to the tail of the boiler flue.

[0024] The water cooling wall 2 mainly includes the lower spiral tube coil, the upper part adopts the vertical tube coil water cooling wall and related connecting pipes and headers, and the spiral tube coil water cooling wall and the vertical tube coil water cooling wall are divid...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the reheater system described in this embodiment includes a primary reheater 4-1, a secondary reheater 4-2, and related pipelines and headers; the primary reheater 4-1 and The secondary reheater 4-2 is arranged at the lower part of the economizer 1 from top to bottom.

[0029] The steam temperature adjustment of the reheater system mainly depends on the reheater desuperheater arranged between the two-stage reheaters, and the inner and outer pipes are cross-connected.

[0030] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 Describe this embodiment, the superheater system described in this embodiment includes a primary superheater 3-1, a secondary superheater 3-2, a tertiary superheater 3-3 and related pipelines and headers, a secondary superheater 3- 2 is located between the first-stage reheater 4-1 and the second-stage reheater 4-2, and the third-stage superheater 3-2 and the first-stage superheater 3-1 are arranged on the second-stage reheater 4-1 from top to bottom The lower part of 2.

[0032] The first-stage superheater 3-1 and the third-stage superheater are arranged in front of the outlet section of the furnace, and mainly absorb the radiant heat in the furnace. The secondary superheater 3-2 is arranged between the primary reheater 4-1 and the secondary reheater 4-2, and absorbs heat by convective heat transfer. The steam temperature adjustment in the superheater system adopts fuel / feed water ratio and two-stage four-point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com