Automatic printed circuit board (PCB) tool storing and taking device and method

A PCB cutting tool, automatic access technology, applied in storage devices, packaging, transportation and packaging, etc., can solve the problems of high cost, low precision, low efficiency, etc., and achieve the effect of low cost, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

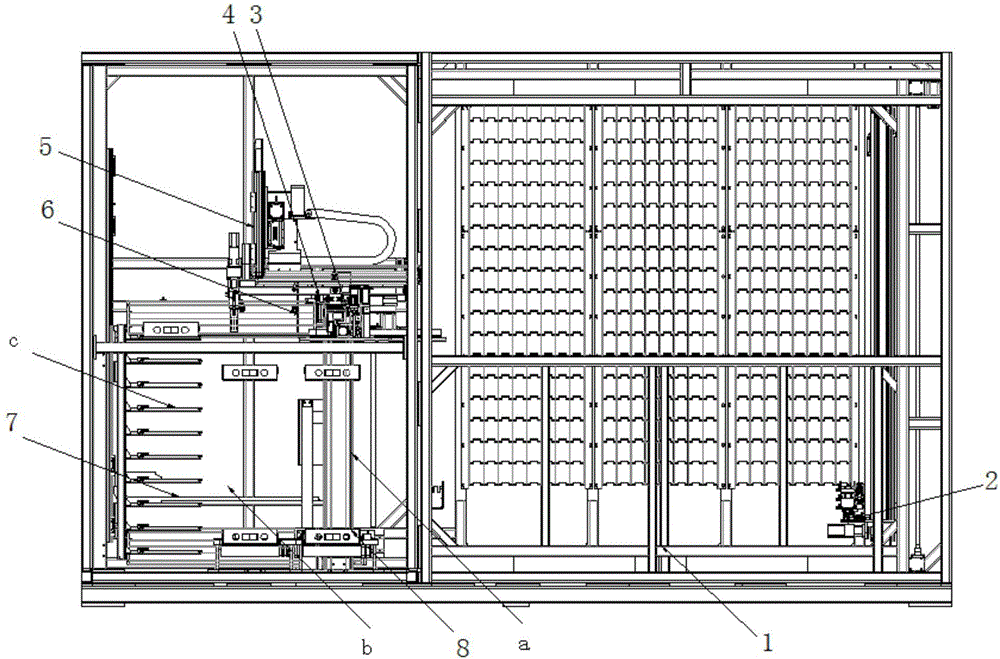

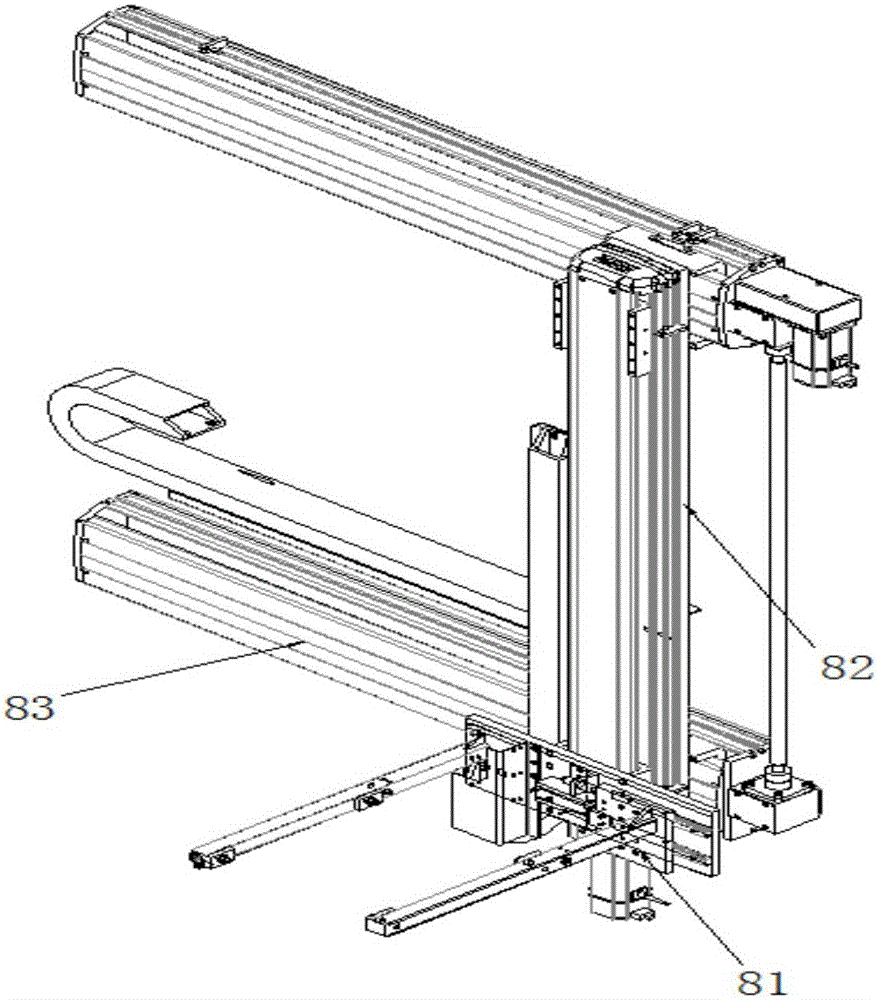

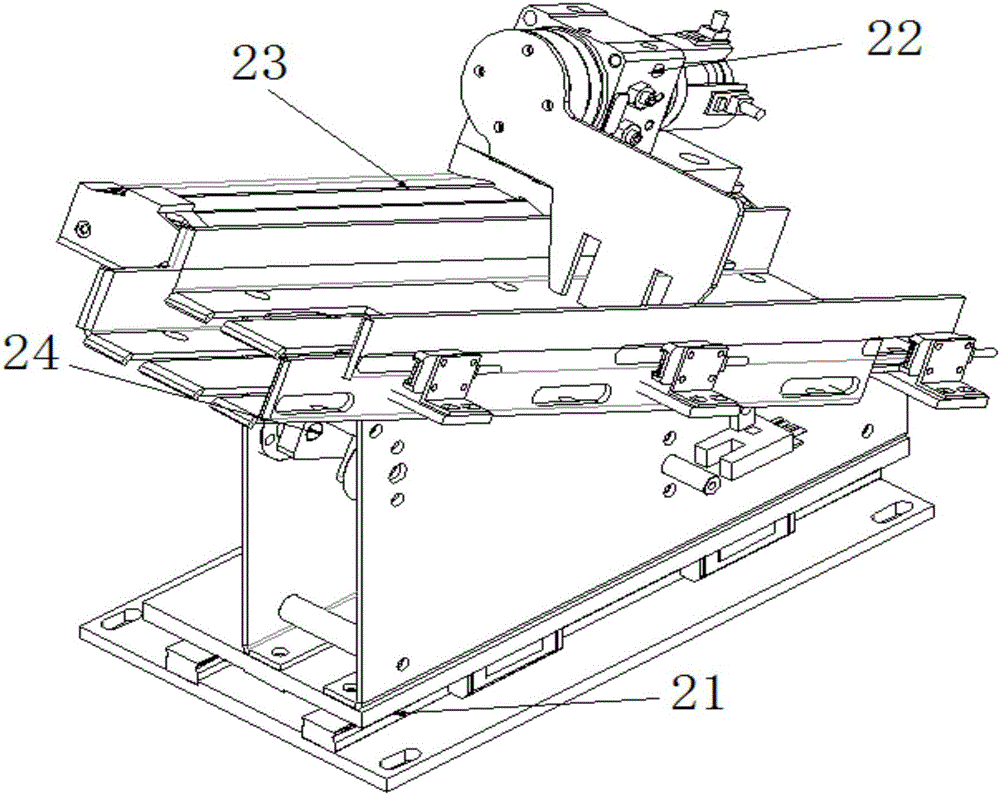

[0046] refer to Figure 1 to Figure 7 , an automatic access device for PCB knives, comprising a storage cabinet, the cabinet shell of the storage cabinet is provided with a new production knives inlet, a knives outlet to be ground, an empty storage box output, and a single box of knives. mouth and human-computer interaction operation control panel, the cabinet body of the storage cabinet is equipped with a feeding trolley for transporting batches of knives, and the storage cabinet 1 is equipped with a control system, an empty storage box conveying system, a storage box handling manipulator, a knives Box grabbing robot, code scanning system, tool box pushing system and tool box access robot.

[0047] Further, the access work area of the storage cabinet includes a material input processing area a, a pin discharge area b to be ground, and an area c to be ground, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com