Electrical test white dot dotting and code spraying continuous conveying mechanism for I-shaped inductor

A technology of I-shaped inductance and conveying mechanism, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of easy error and low efficiency, and achieve the effect of avoiding errors, avoiding manual work, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

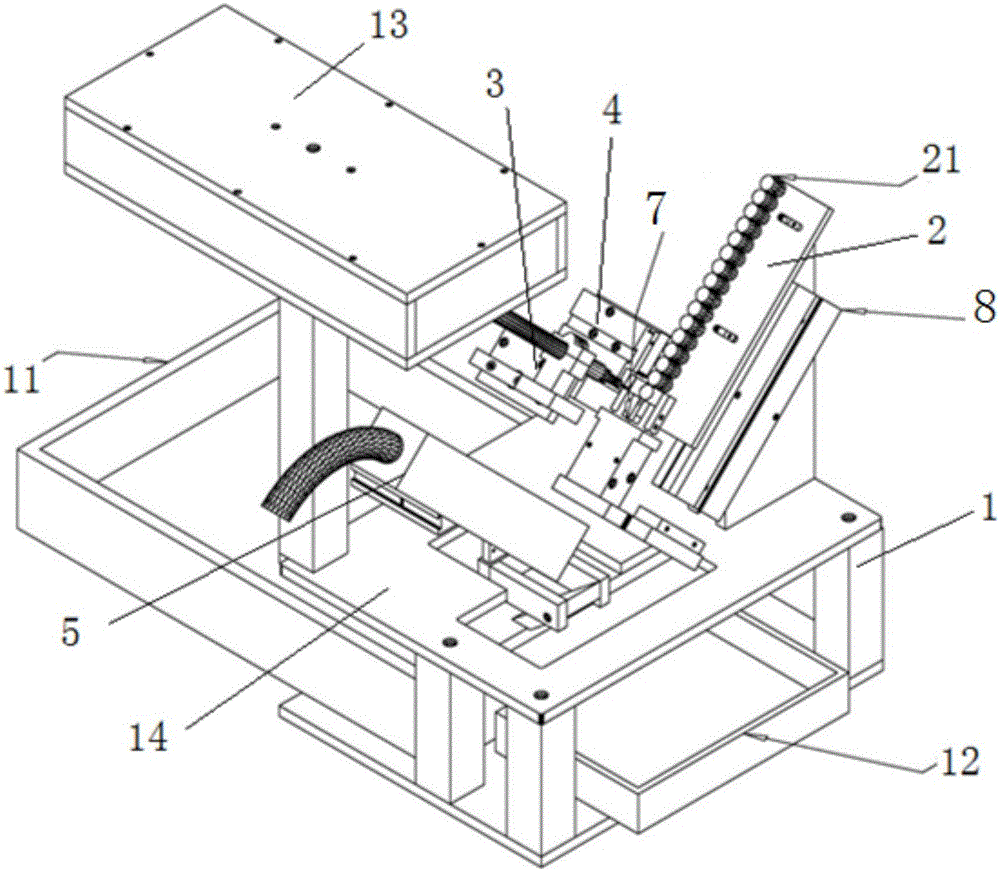

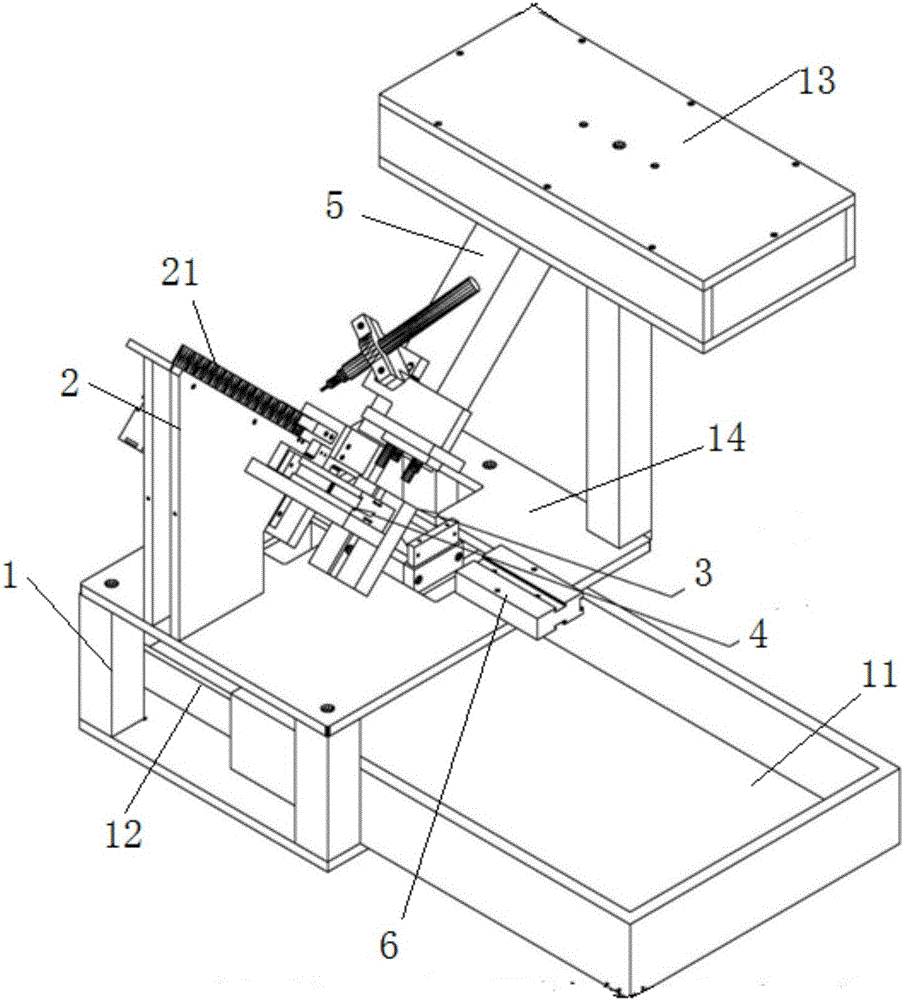

[0012] The invention is used to complete the electrical performance test, direction marking and coding of I-shaped inductors, which can be completed by one machine, which improves the quality of coding and white dots, eliminates the misjudgment rate of good products and defective products, and improves efficiency at the same time .

[0013] Such as figure 1 and figure 2 As shown, an I-shaped inductive coding point and white point test all-in-one machine includes a frame 1, and the frame 1 includes a bottom plate and a top plate 14 arranged above the bottom plate, and a column is arranged between the bottom plate and the top plate 14 support. The frame 1 is provided with an electric control box 13, an inductance transfer device 8, an inductance delivery device 2, an inductance marking device 3, an inductance testing device 4, a coding device 5, a good product inductance screening device 6, and an inductance positioning device above the top plate 14. 7. A classified storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com