Method for controlling container handling trolleys

A technology for handling trolleys and control methods, which is applied in the field of warehousing, and can solve problems such as unsatisfactory container handling operations, complicated operations by staff, and heavy workload, and achieve the effect of small size, flexible movements, and stable handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

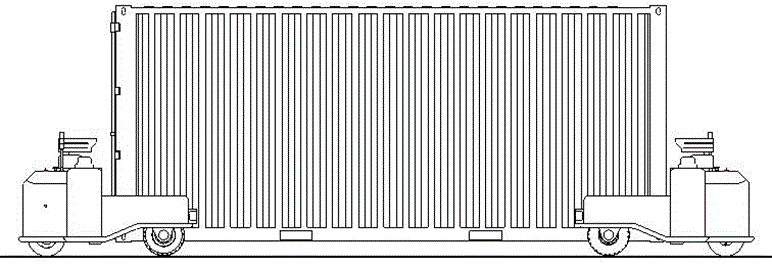

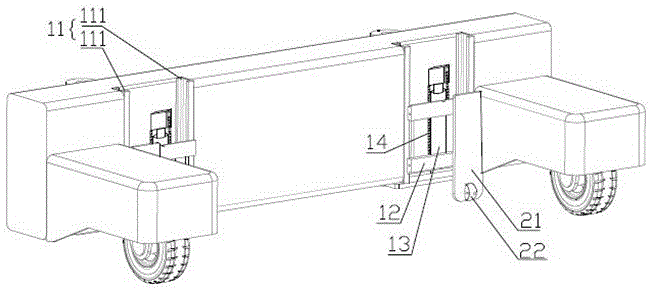

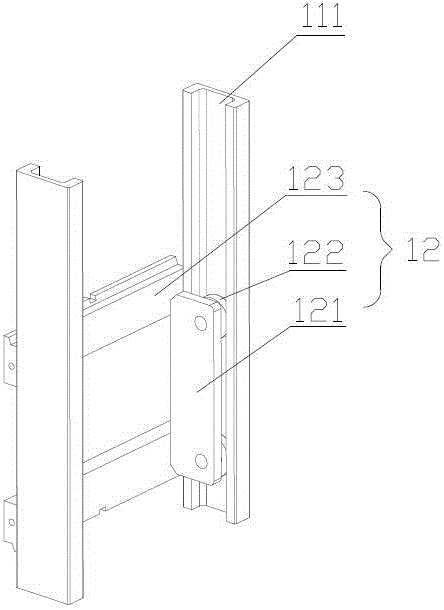

[0040] Example 1, such as Figure 1-3 As shown, the present invention provides a control method for a container handling trolley, which is used in a container handling system. The container handling system includes a wireless main controller and a handling trolley. The handling trolley is provided with an action execution controller connected to the action Execute the controller's electric drive wheel device, hydraulic lifting device, and measuring components. The measuring components include a camera installed in the middle of the bonding end face of the transport trolley, a laser positioner and a distance measuring device respectively located at symmetrical positions on both sides of the bonding end face of the transporting trolley. The device, the displacement sensor of the oil cylinder in the hydraulic lifting device, the action execution controller receives the communication signal from the wireless main controller, and controls the electric drive wheel device, hydraulic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com