A Method of Using Cable Heating and Optical Fiber Temperature Measurement to Comprehensively Detect the Quality of Grouting after Pile Foundation

An optical fiber temperature measurement and comprehensive detection technology, which is applied in the testing of infrastructure, infrastructure engineering, construction, etc., can solve the problem of difficulty in judging the quality of grouting construction, and achieve the effect of improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

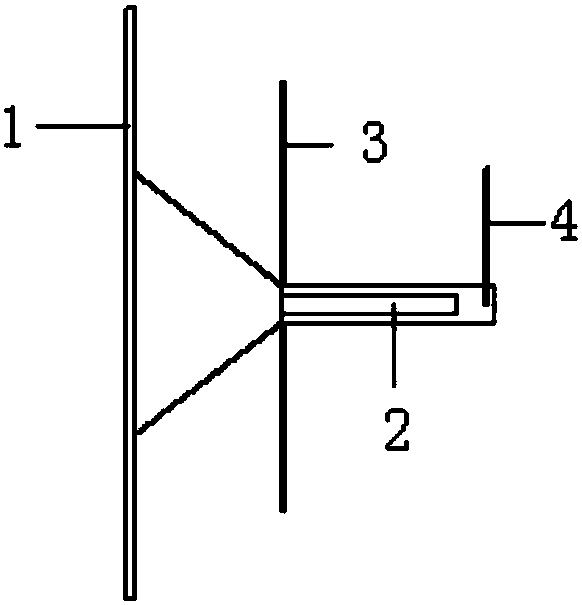

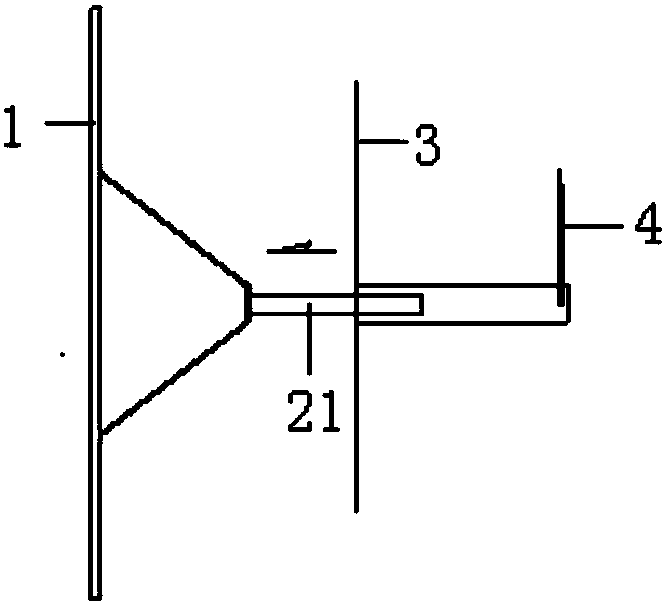

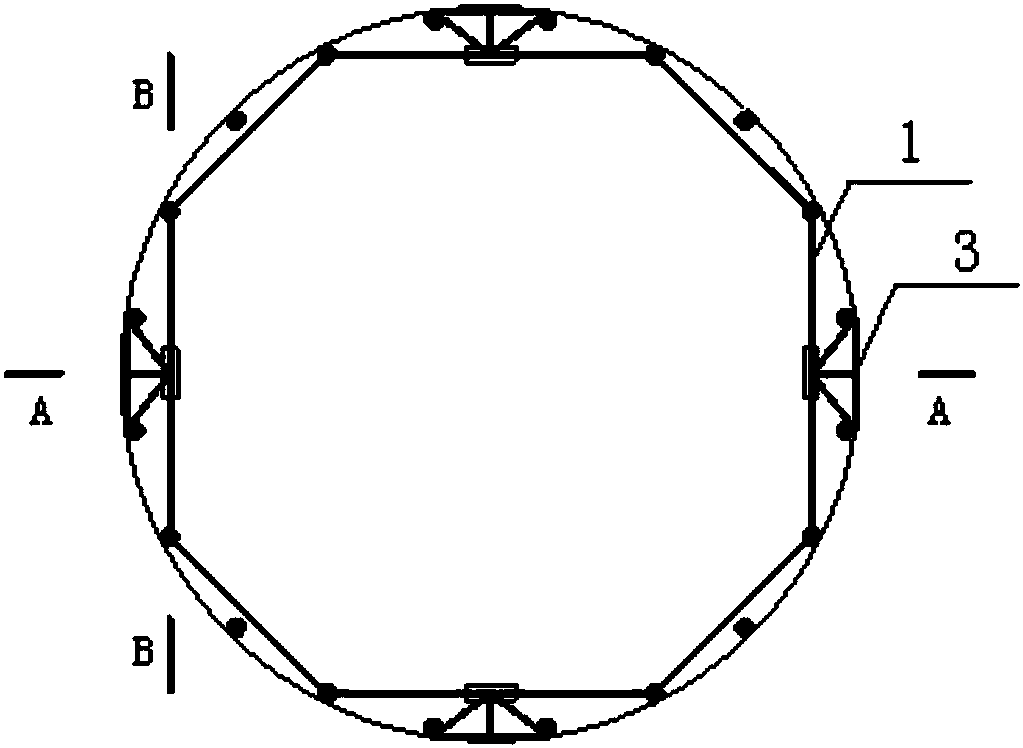

[0034] refer to Figure 1a to Figure 7 , a method for comprehensively detecting the quality of grouting after pile foundation by using cable heating and optical fiber temperature measurement, including the following steps:

[0035] (1), installation of heating cable and sensing optical fiber combination device: multiple heating cables with hydraulic cylinders or pneumatic cylinders 2 and sensing fiber combination device 1 are fixed on the main rib 51 of the steel cage, and the heating cable and sensor Sensing optical fiber combination device 1 is fixedly connected with the piston rod 21 of hydraulic cylinder or pneumatic cylinder 2, and the acquisition signal input end of external acquisition instrument 7 is connected with the output end of heating cable and sensing optical fiber combination device 1; The sensing optical fiber combination device 1 is arranged in a U-shaped structure, and is arranged from the bottom of the steel cage upwards; the measuring cable, hydraulic pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com