Self-compacting spiral steel pile

A self-compacting, spiral steel technology, applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of increased pile side resistance, unfavorable environmental protection, and insufficient soil contact, so as to increase pile side resistance and improve resistance. The effect of compressive and pull-out capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

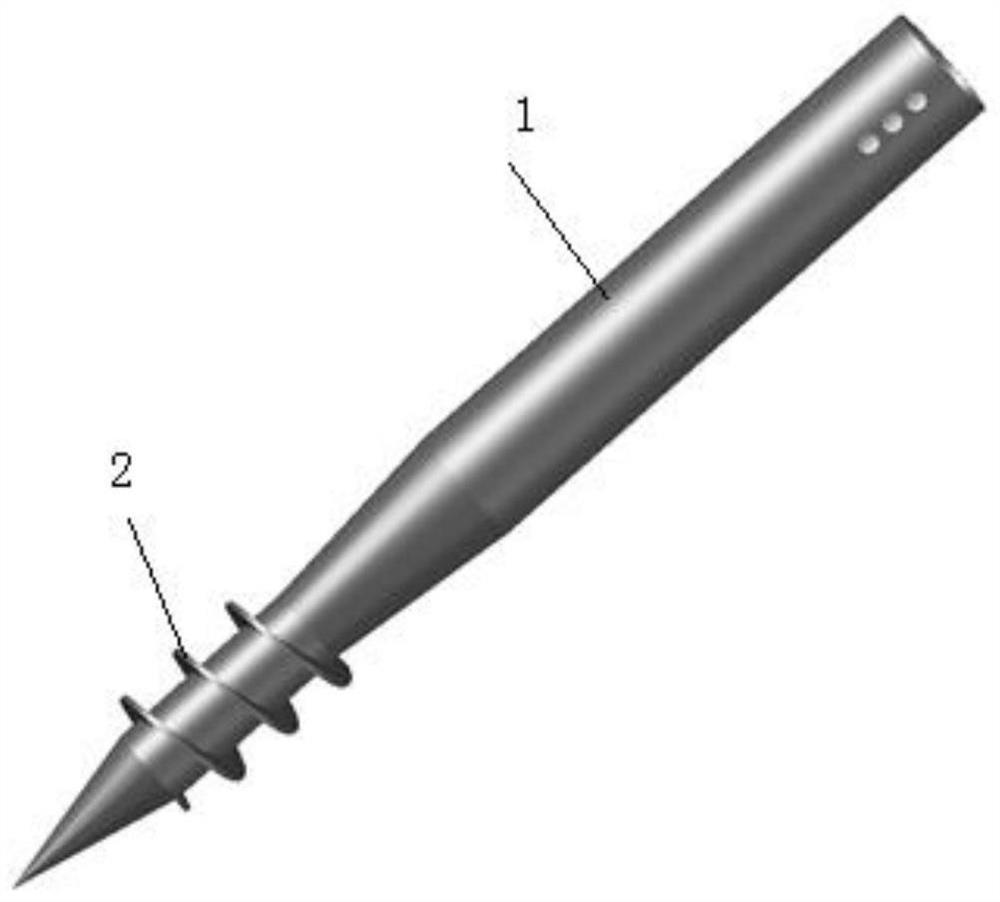

[0011] Such as figure 1 As shown, the present invention discloses a self-compacting spiral steel pile, comprising a pile body 1 and a helical blade 2, the helical blade 2 is arranged on the outer wall of the front end of the pile body 1, and the diameter of the pile body above the helical blade 2 is enlarged .

[0012] The diameter of the pile body 1 at the position above the helical blade 2 is greater than or equal to the outer diameter of the helical blade 2 .

[0013] The head of the spiral steel pile is conical, and the spiral blade 2 is located above the conical shape.

[0014] The helical blade 2 is a spiral wound on the outer wall of the pile body.

[0015] The main feature of the self-compacting spiral steel pile of the present invention is that the pile diameter at the position above the spiral blade of the spiral steel pile is enlarged, and the pile diameter can be greater than or equal to the outer diameter of the spiral blade.

[0016] Finally, it should be note...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com