An anti-seismic prefabricated partition wall and its construction method

A prefabricated assembly and partition technology, applied in walls, protective buildings/shelters, buildings, etc., can solve the problems of lack of earthquake resistance, difficulty in industrialization, waste of materials, etc., and achieve good promotion value and work efficiency Improve and realize the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

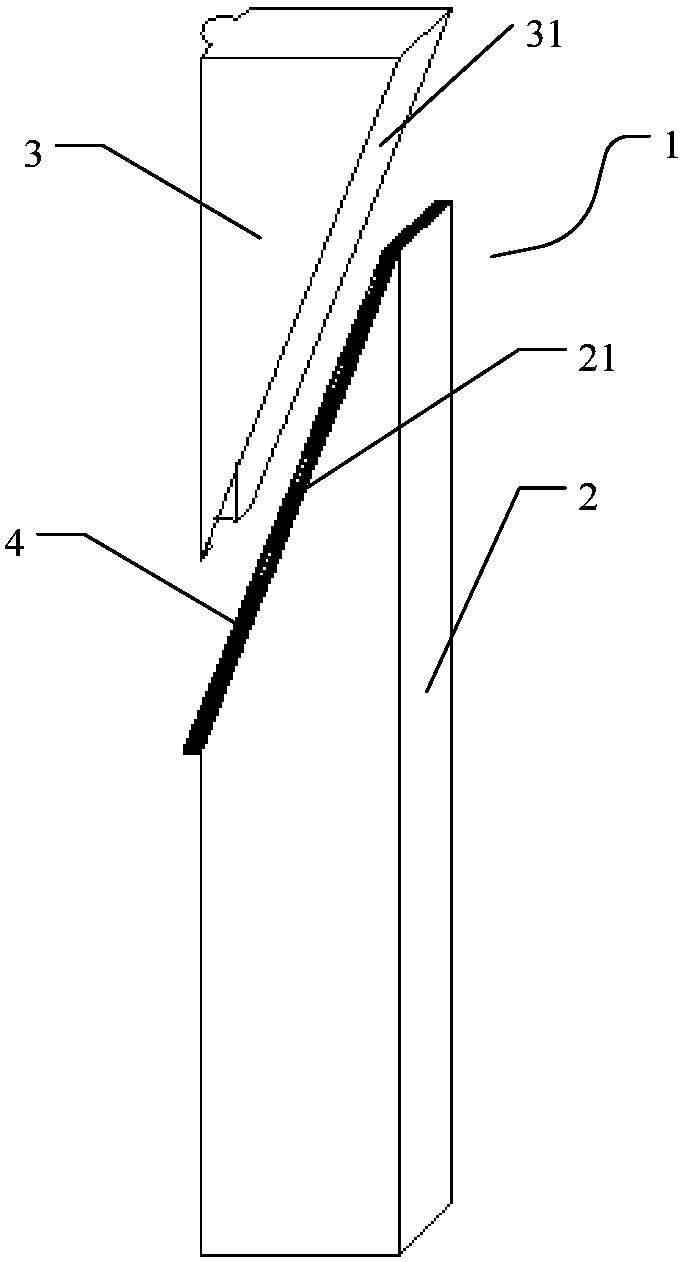

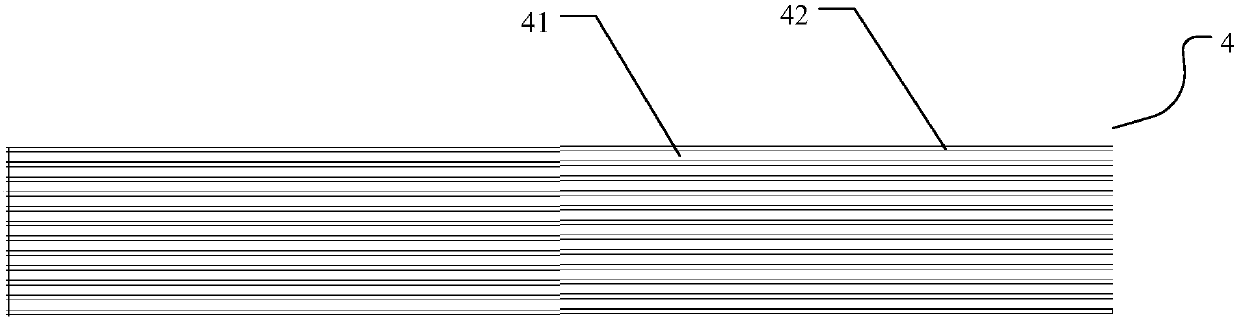

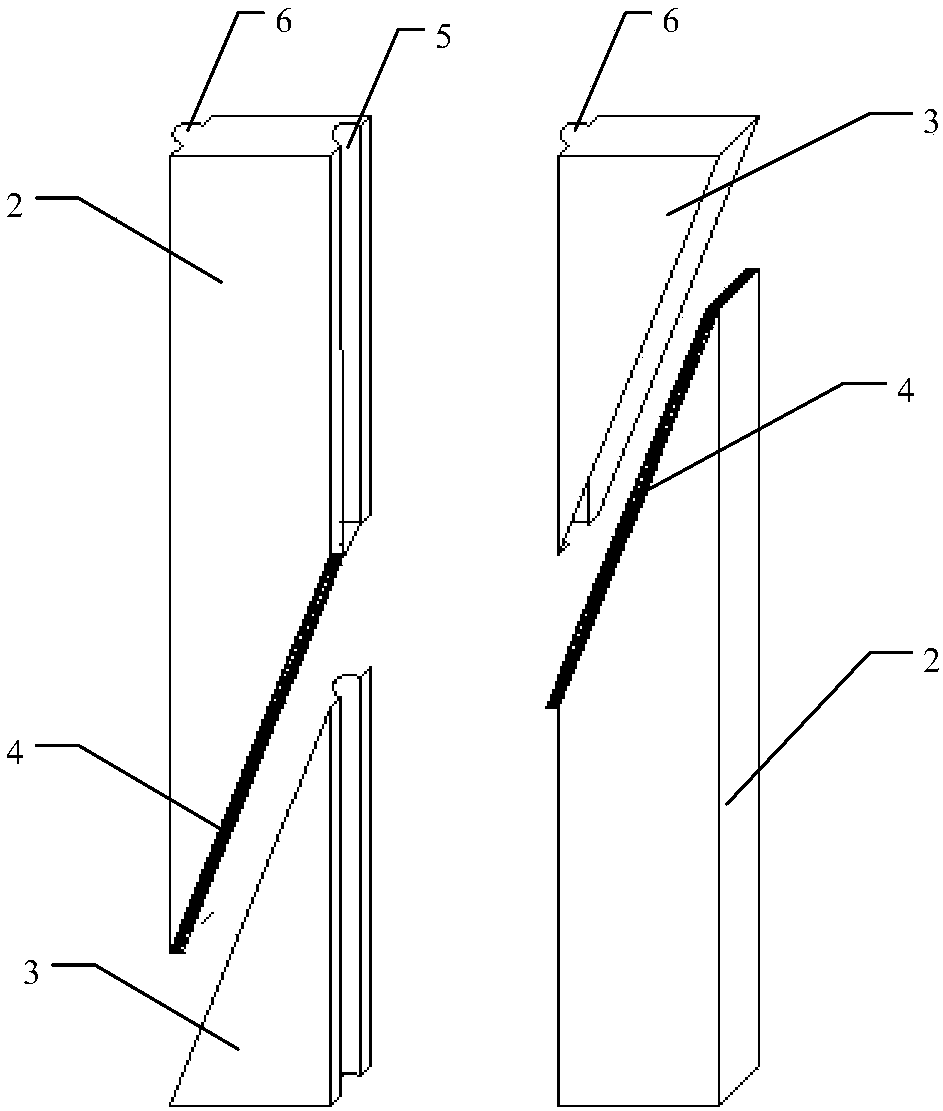

[0065] Such as Figure 1 to Figure 6 As shown, a kind of anti-seismic prefabricated partition wall includes a cuboid partition wall panel 1, and the cuboid partition wall panel 1 includes a first partition wall unit panel 2 and a second partition wall unit panel 3, and the first partition wall The unit panel 2 is provided with a first partition wall slope 21, and the second partition wall unit panel 3 is provided with a second partition wall slope 31, and the slope and size of the first partition wall slope 21 and the second partition wall slope 31 are Similarly, the first partition wall slope 21 and the second partition wall slope 31 are connected by a laminated rubber member 4, and the first partition wall slope 21, the second partition wall slope 31 and the laminated rubber member 4 TB1521 industrial adhesive is used for bonding between them; the side wall of the rectangular parallelepiped partition wall 1 in the length direction is provided with a mortise 5, and the opposi...

Embodiment 2

[0076] A construction method of the anti-seismic prefabricated partition wall of embodiment 1, comprising the following steps:

[0077] Step A: Install the cuboid partition board first, then align the tenon of the cuboid partition board with the tenon of another cuboid partition board for splicing, connect the cuboid partition boards together in turn, and adjust the verticality and adjacent boards flatness of the surface;

[0078] Step B: lay out the wires on the ground and ceiling panels, and install the cuboid partition wall panels in sequence from one end of the main wall or column to the other end, and when there is a door opening, install it from the door opening to both sides;

[0079] Step C: Install the positioning board first, scrape the adhesive material at the groove and top surface of the cuboid partition wall board, seal the upper end of the cuboid partition wall board, align the positioning board up and down, and the cuboid partition wall board The lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com