Ceiling-mounted gypsum board

A gypsum board, hoisting technology, used in building components, buildings, ceilings, etc., can solve the problems of low secondary utilization, high maintenance costs, waste of resources, etc., to enhance secondary utilization, reduce maintenance costs, and reduce resources. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

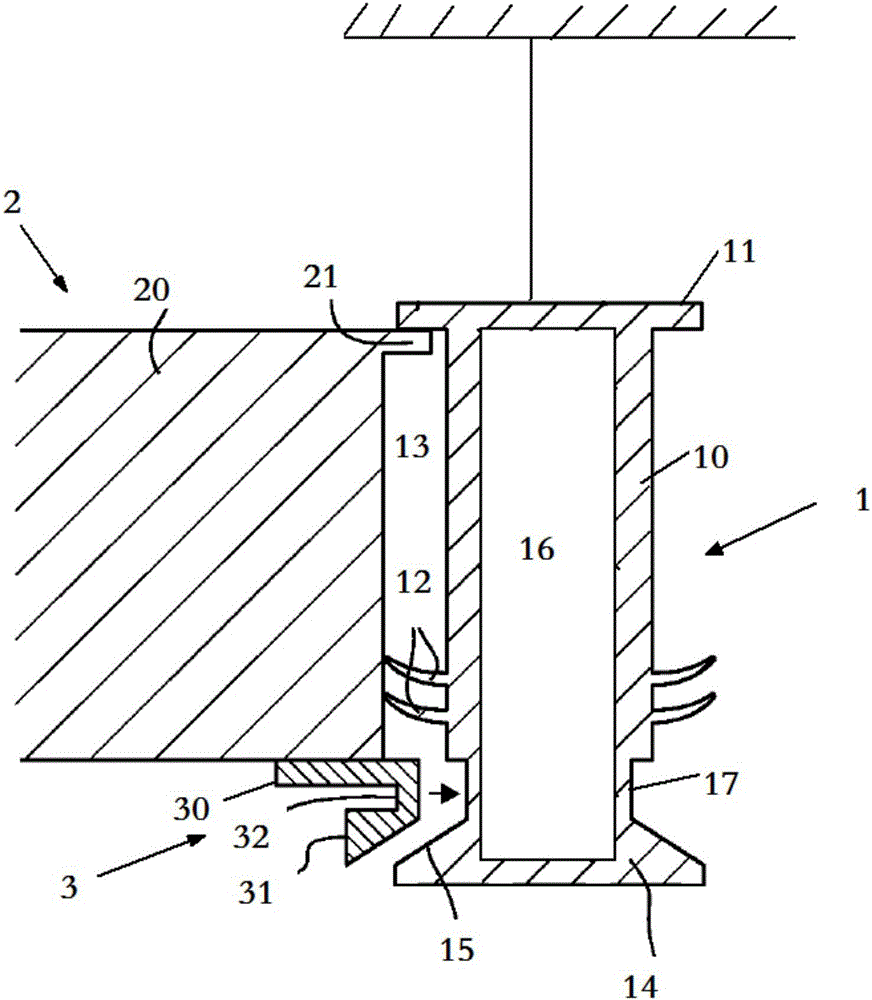

[0023] Such as figure 1 As shown, a hoisting gypsum board includes a keel 1 and a gypsum board 2 installed on the keel. The keel 1 is fixed on the bottom of the floor through hanging ribs. The keel 1 includes a keel main body 10, and the top of the keel main body 10 protrudes to both sides. There is an upper block 11, the bottom of the keel main body 10 is provided with a lower block 14 protruding to both sides, the lower block 14 has an inclined upper surface 15, and the two sides of the keel body 10 on the top of the lower block 14 are provided with fixed Groove 17. The two sides of the keel main body 10 are located on the upper part of the fixing groove 17, and arc-shaped elastic blocks 12 protrude to both sides. The ends of the elastic blocks 12 are inclined upward. In this implementation, each side of the keel main body 10 has two arc-shaped elastic blocks, arranged in parallel up and down.

[0024] In order to reduce the weight of the keel 1 , the center of the keel ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com