Forced continuous sprag clutch

A clutch and continuous technology, applied in the direction of clutches, one-way clutches, magnetic drive clutches, etc., can solve the problems of easy breakage of wedges, rising manufacturing costs, and wear of spring surfaces, so as to improve equipment safety and reliability. Effects of avoiding clutch failure and improving wedge strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

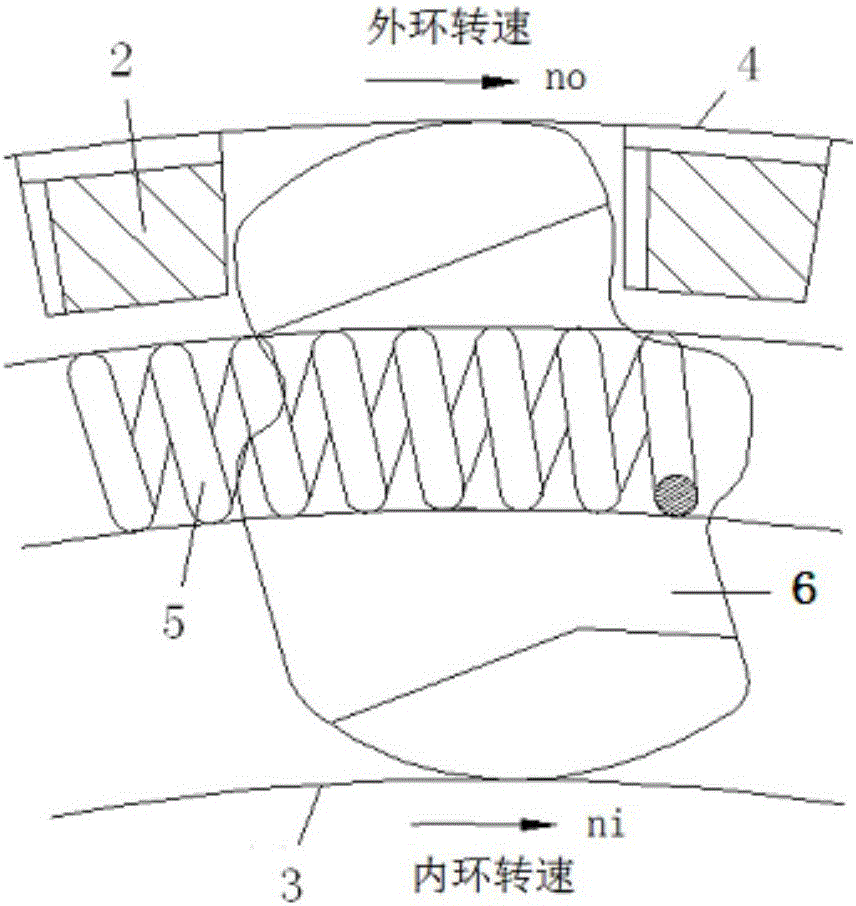

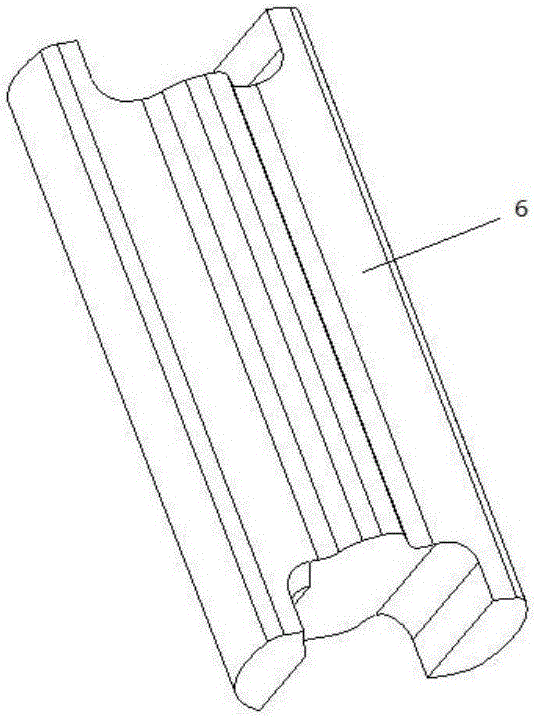

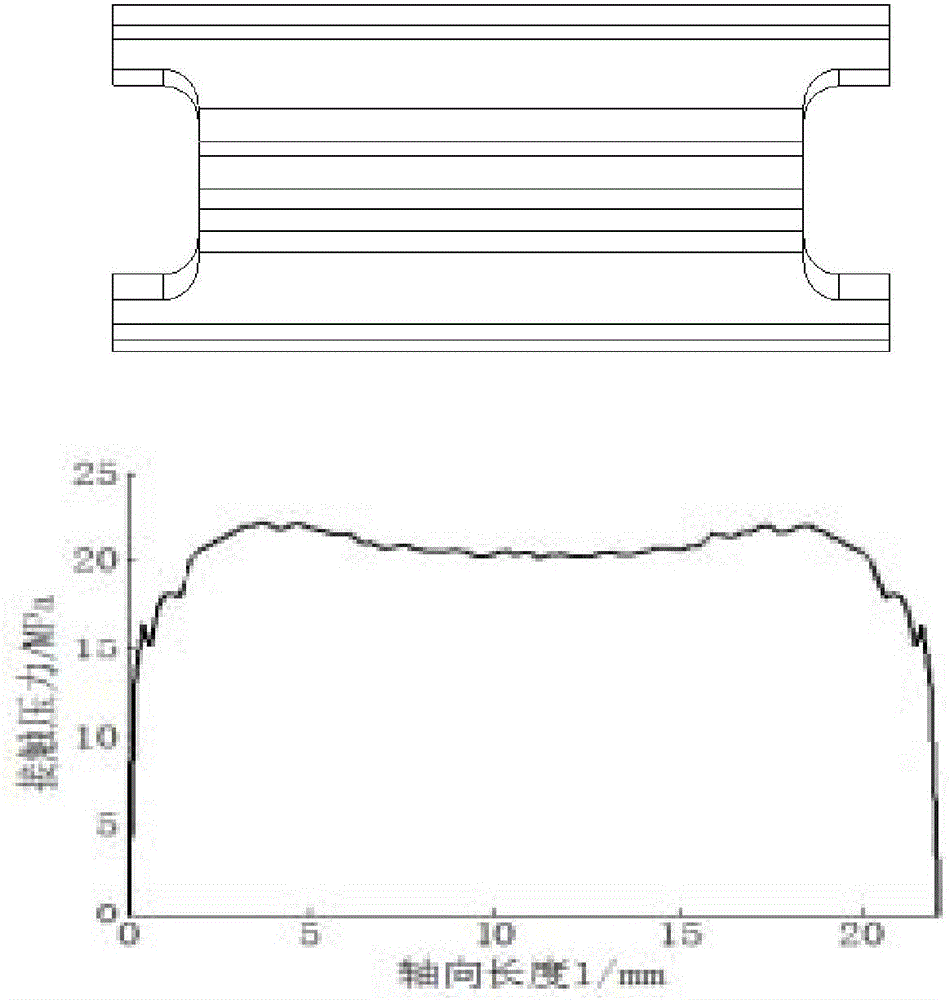

[0019] see Figure 4 and Figure 5 , the forced continuous sprag clutch provided by the present invention is composed of a cage 2, an inner ring 3, an outer ring 4 and a weak magnetic wedge 1. The end face of the weak magnetic wedge 1 is a planar structure; the inner ring 3 and the outer ring 4 It is a ferromagnetic material, and the cage 2 is a non-ferromagnetic material.

[0020] Specifically, the magnetic attraction force F between the weak magnetic wedge 1 and the inner ring 3 and outer ring 4 is controlled within 0.62-0.93N.

[0021] The magnetization B of the weak magnetic wedge 1 is calculated by the formula: F=(B / 4965)2*S, where F is the magnetic force kgf; B is the magnetic flux density G; S is the area perpendicular to the magnetic flux density cm 2 .

[0022] Specifically, the material of the weak magnetic wedge 1 is GCr15; the material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com