Self-adaption automatic separation drive assembly and overrunning clutch thereof

A technology of overrunning clutch and drive assembly, which is applied in the direction of clutch, one-way clutch, transmission control, etc., can solve the problems of unstable mechanical performance, high market maintenance rate, low assembly efficiency, etc., and achieve low cost, simple structure, The effect of quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

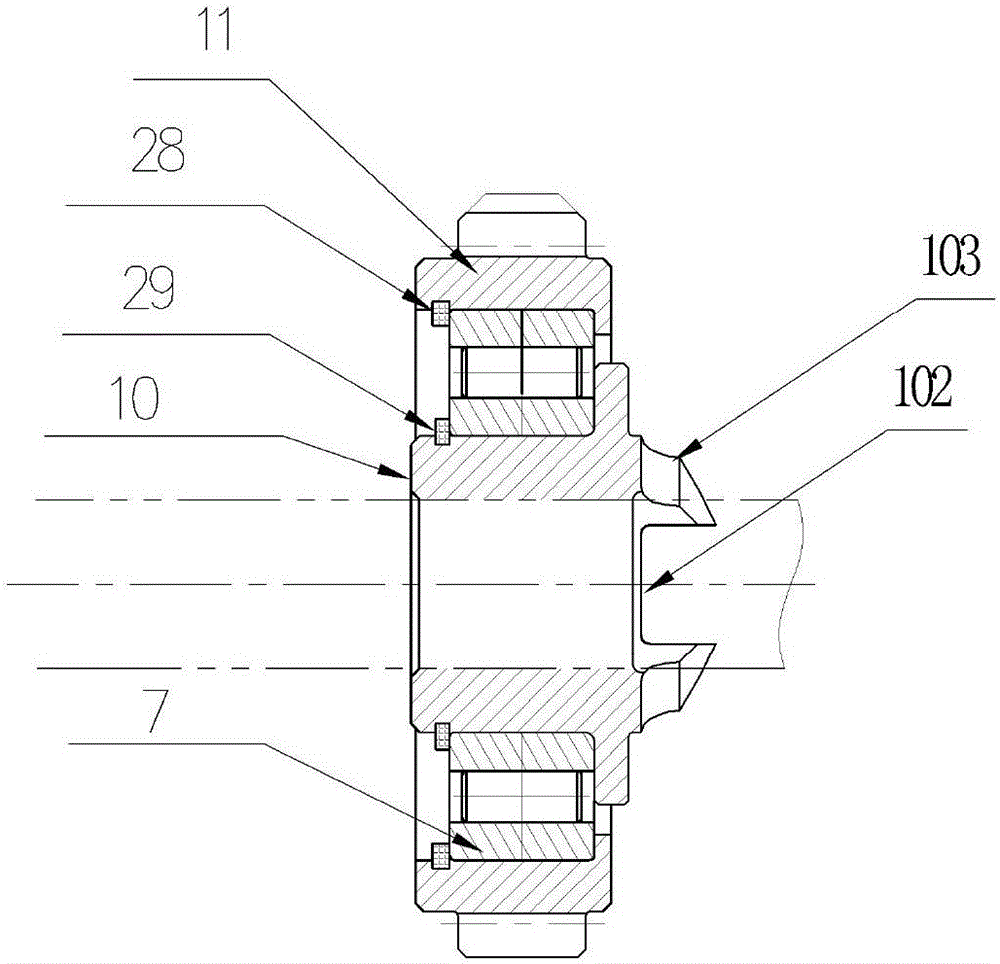

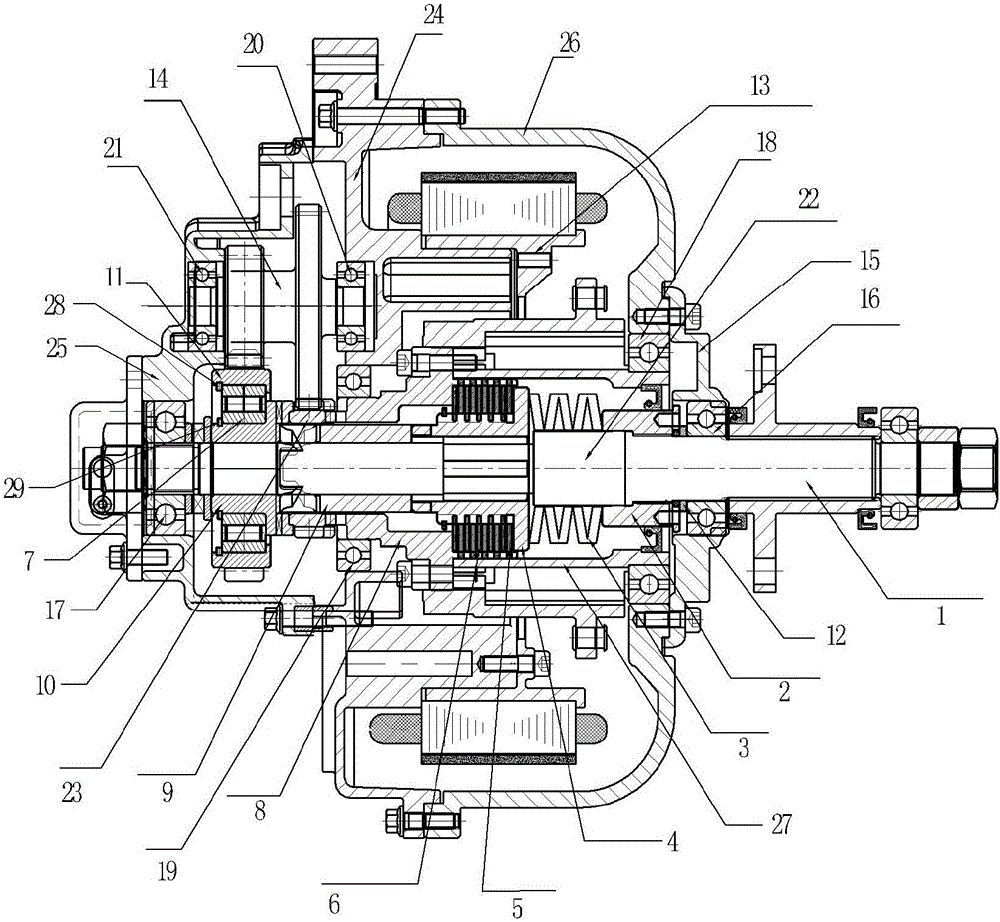

[0030] Examples, see Figures 1 to 4, an overrunning clutch used to cooperate with the clutch assembly, which includes a gear 11, a one-way bearing 7 and a one-way limiting helical cam 10. Wherein, the gear 11 is connected with the one-way limiting helical cam 10 through the one-way bearing 7; . A first clip spring 28 for limiting the position of the one-way bearing 7 is provided on the inner diameter of the gear 11 , and a second clip spring 29 for limiting the position of the one-way bearing 7 is provided on the outer diameter of the one-way limiting helical cam 10 .

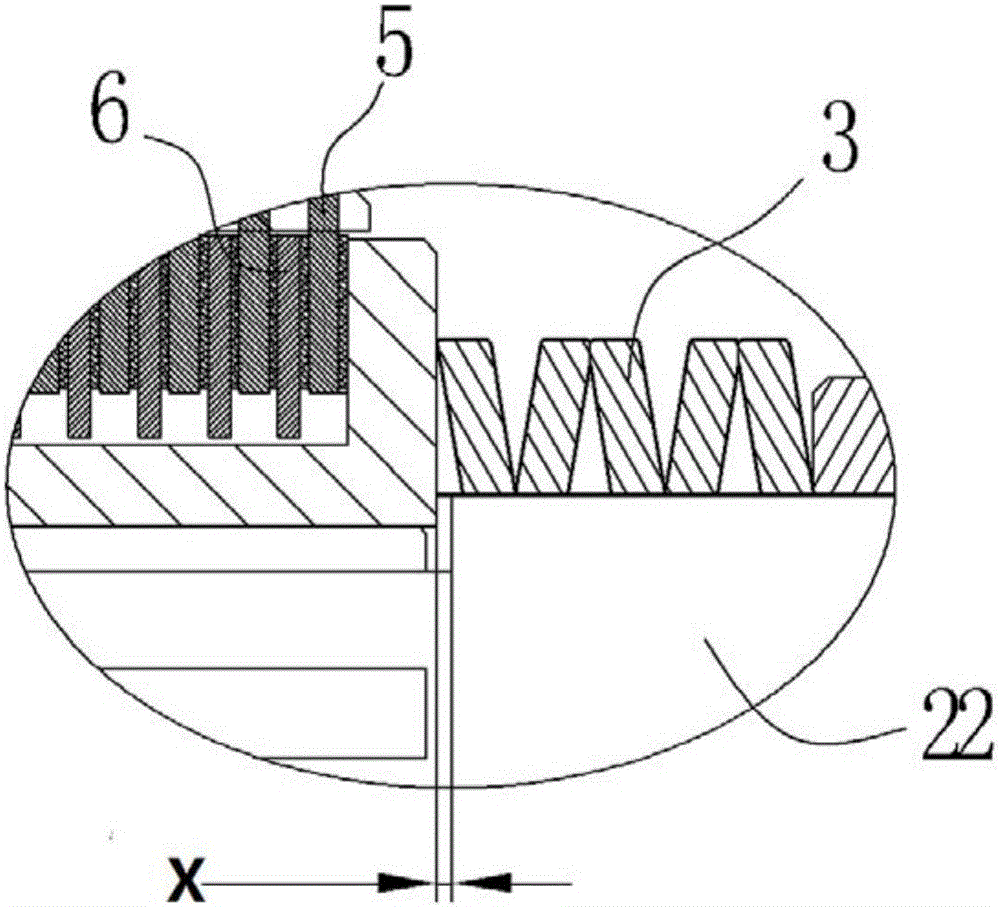

[0031] One end of the one-way limiting helical cam 10 is provided with a helical surface 103, and the axial center position of the helical surface 103 has a groove 102 for matching with the thrust limiting helical cam 9, and the inner diameter of the groove 102 is larger than that of the cam. diameter of. Driven by the gear 11, the one-way limiting helical cam 10 axially presses the thrust limiting helical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com