Large-caliber all-welded ball-valve integrated multifunctional detection equipment

A fully welded ball valve and testing equipment technology, applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, measuring devices, etc., can solve problems such as inability to clean air, inconvenience, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

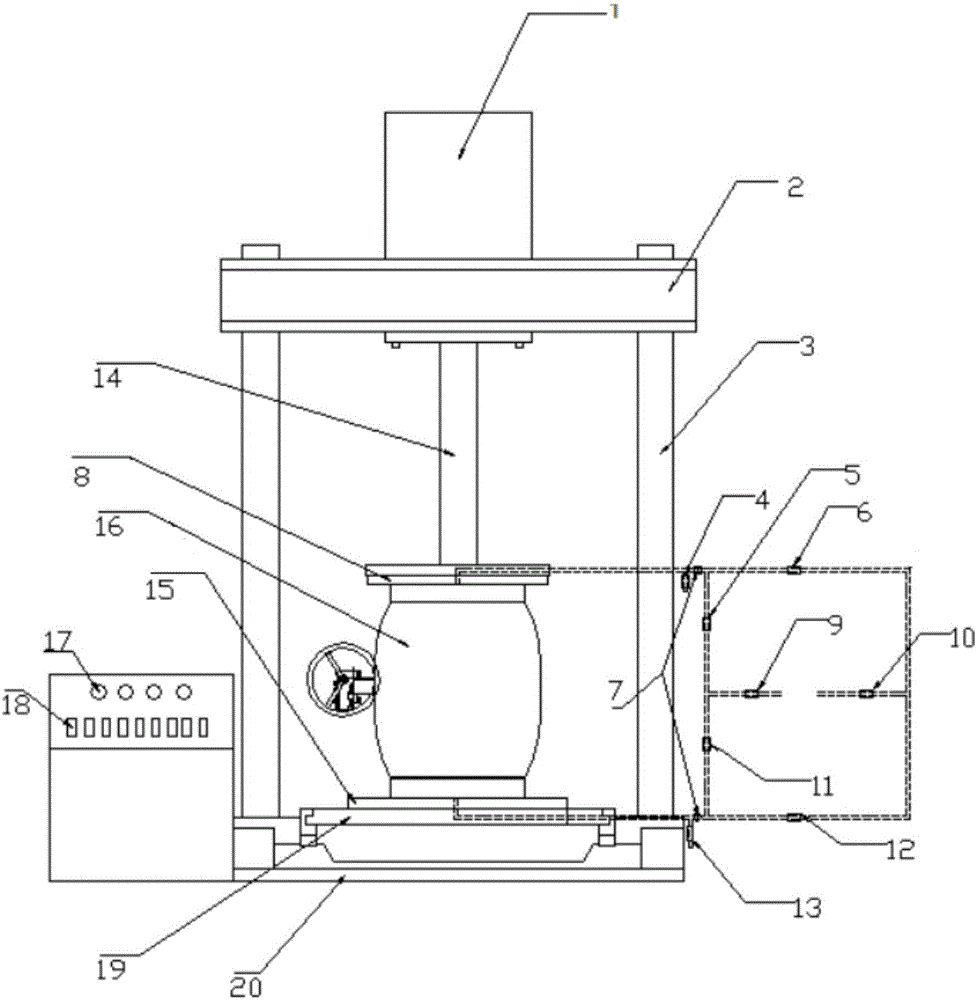

[0018] Such as figure 1 A large-diameter all-welded ball valve integrated multi-functional testing device shown includes a base 20, a main frame 2, a mobile vehicle 19, a lower sealing plate 15, an upper sealing plate 8, a detection system and a control box. The frame 2 is connected above the base 20 through the force bearing shaft 3. The base 20 is provided with two horizontal rails. The mobile vehicle 19 is movably connected between the two horizontal rails. The lower sealing plate 15 Installed on the upper surface of the mobile vehicle 19, the upper sealing plate 8 is arranged between the base 20 and the main frame 2, the upper sealing plate 8 is connected with the cylinder body 1 through the upper pressing plate 4, and the cylinder body 1 is installed on the main frame 2, and the detection system includes an upper detection tube, a lower detection tube, a water supply pipeline 10, an air supply pipeline 9, an upper discharge valve 4, a lower discharge valve 13 and a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com