An ultra-precise intelligent alignment system for screen connectors

An ultra-precision, connector technology, applied in the direction of digital control, electrical program control, etc., can solve the problems that are not conducive to enterprise development, not suitable for mass production, and low production efficiency, so as to achieve automatic production operations, improve quality and Yield rate and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

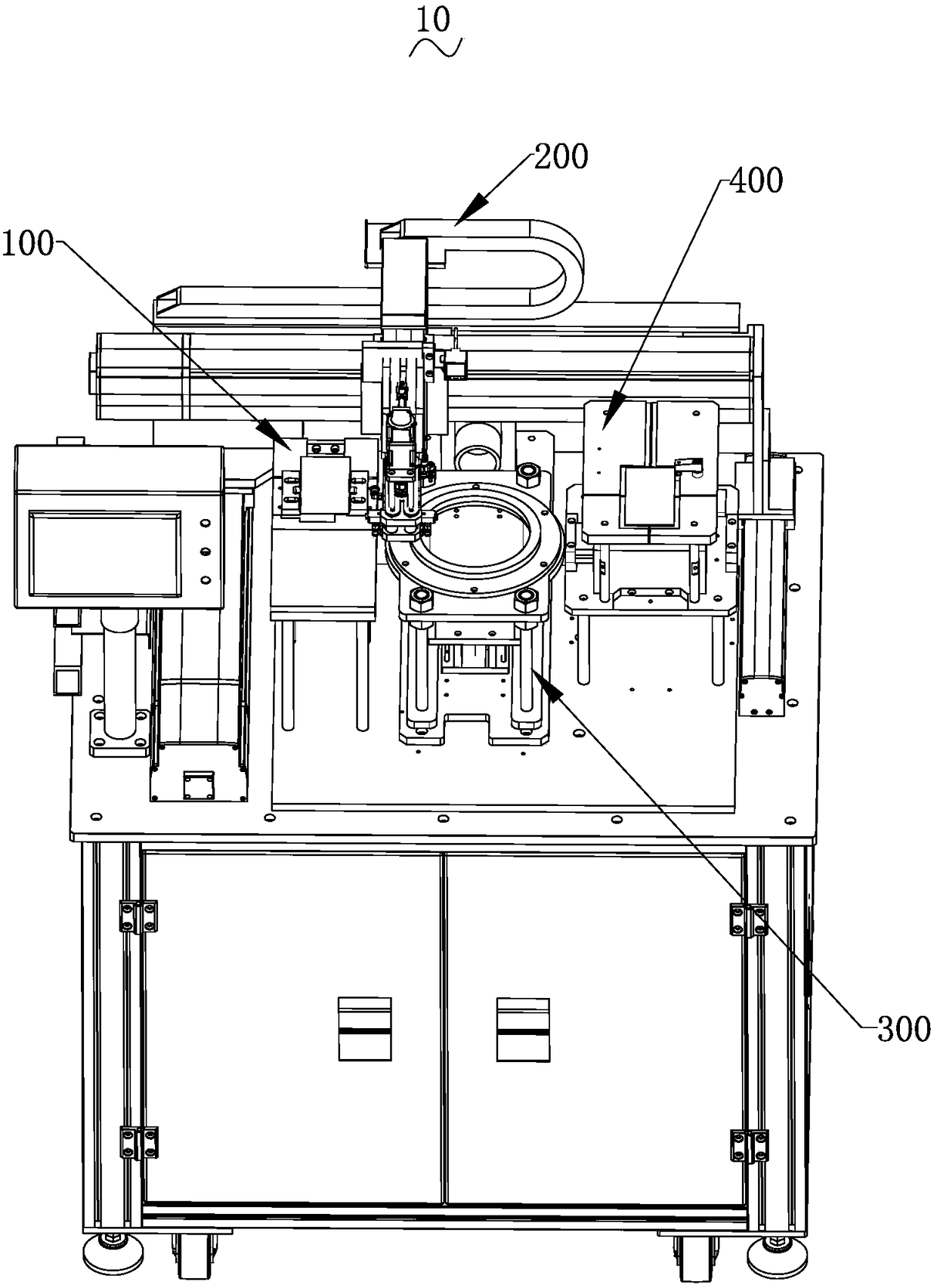

[0033] like figure 1 Shown is a structural diagram of an ultra-precision intelligent alignment system 10 for a screen connector according to an embodiment of the present invention. The positioning device 100, the mobile device 200 for sucking and moving the screen connector, the visual measurement and imaging device 300 for sampling and imaging the screen connector, and the ultra-precision device for communicating the screen connector and the ARM industrial control board are connected. Probe module device 400 .

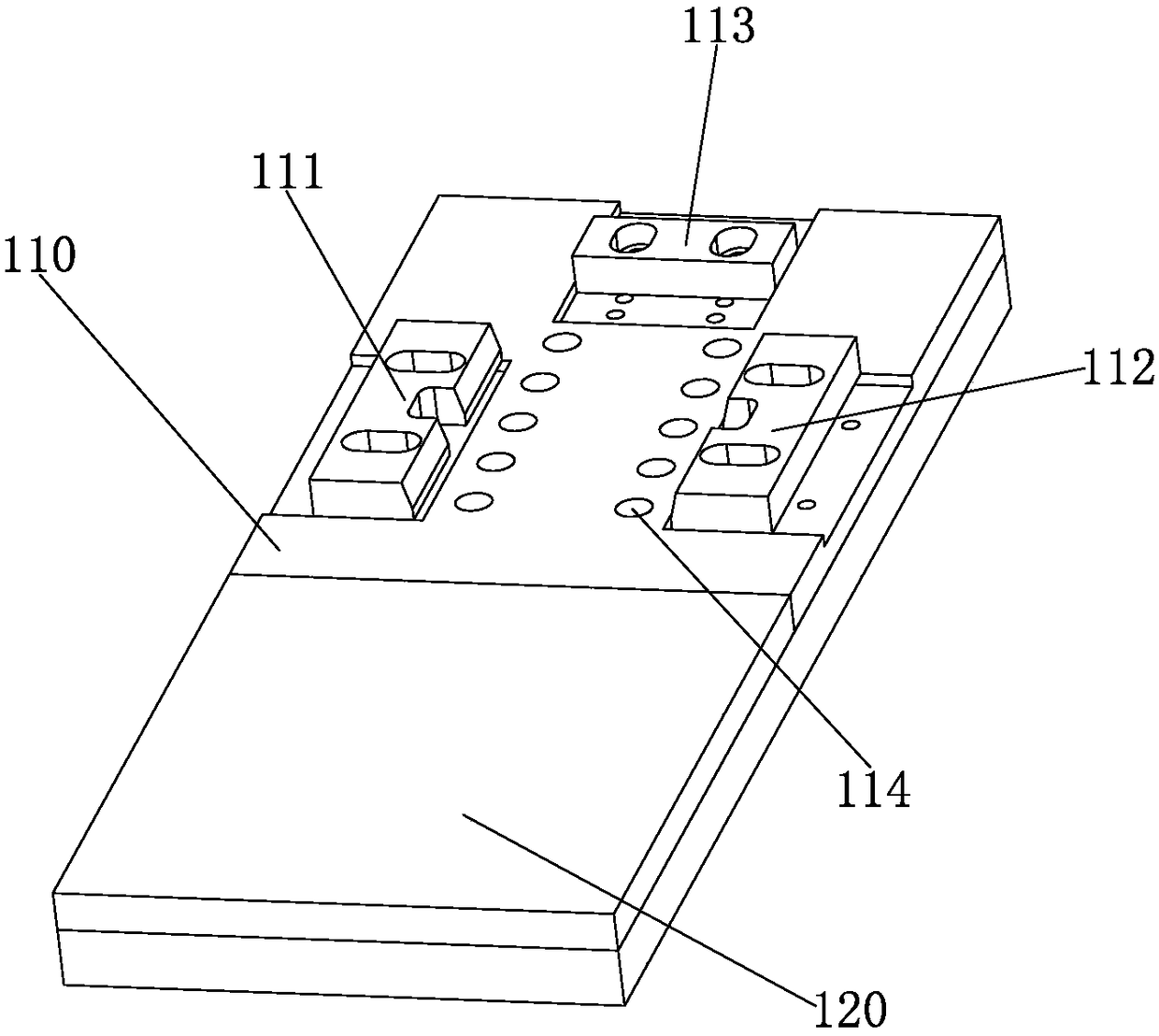

[0034] like figure 2 As shown, the initial positioning device 100 includes a screen placement panel 110 for placing the screen and an FPC support plate 120 for placing the FPC connected to the screen. The screen placement panel 110 and the FPC support plate 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com