Design method of completely-assembling frame of low-rise building

A design method and fully assembled technology, applied in the directions of architecture, building construction, calculation, etc., can solve the problems of inappropriate design of beam-column frames with semi-rigid joints, and achieve the effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] The design method of the fully assembled frame of the low-rise building of the present embodiment comprises the following steps:

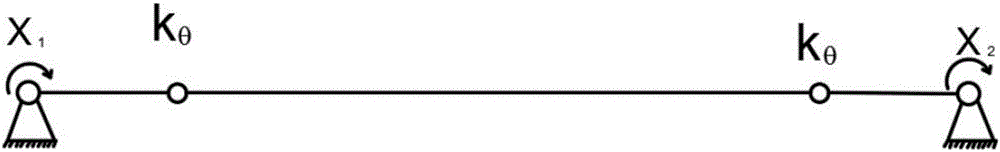

[0021] Step 1: Design the first joint connecting the beam on the column, design the second joint connecting the column on the beam, and connect the first joint and the second joint by bolts;

[0022] Step 2: Calculate the different initial stiffness values of the beam-column joints;

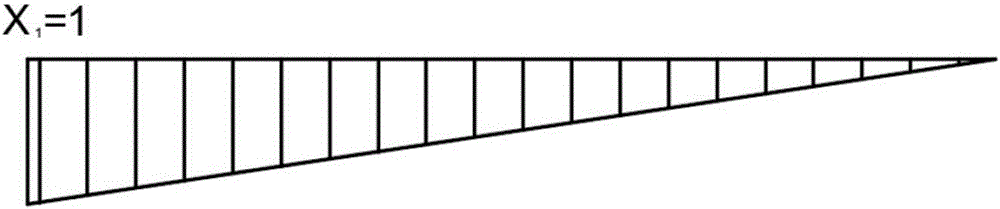

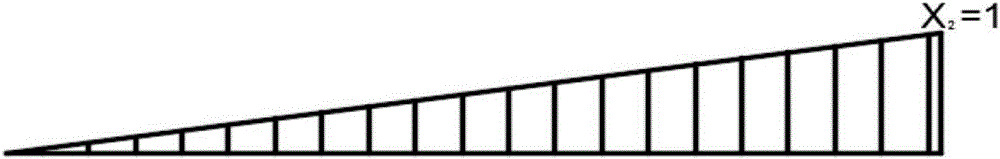

[0023] Step 3: Make the bending moment diagram of the beam according to the specified load and different initial stiffness values;

[0024] Step 4: Set the corresponding beam and column dimensions according to the bending moment diagram; there are various dimensions and specifications of beams and columns that meet the force requirements set in this step;

[0025] Step 5: Take economy as the selection criterion, and select the most e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com