Modal analysis method under influence of impeller structure thermal stress on the basis of ANSYS

A modal analysis and structural thermal technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve problems such as operation accidents, rotor instability, engine structure damage, etc., and achieve the effect of a reliable theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described with reference to the accompanying drawings and embodiments of the specification.

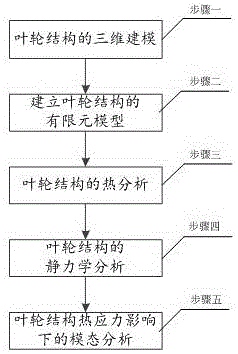

[0016] Such as figure 1 Shown is a working flow chart of the modal analysis method under the influence of the thermal stress of the impeller structure based on ANSYS in the present invention. There are mainly 2 major components, which are realized by two softwares. The detailed steps are as follows:

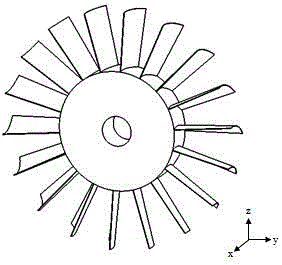

[0017] Step 1: 3D modeling of the impeller structure, using the solidworks parametric modeling method for 3D modeling to obtain a 3D model of the impeller structure, such as figure 2 shown;

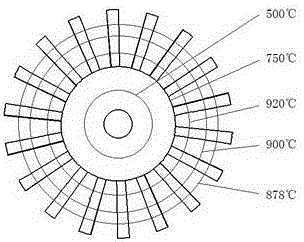

[0018] Step 2: Establish the finite element model of the impeller structure, import the three-dimensional model of the impeller structure into the finite element analysis software ANSYS, and complete the setting of the unit type, material properties, and material parameters in the pre-processing module of the ANSYS software, and divide the finite elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com