Connection system for total-prefabricated concrete structure

A prefabricated concrete and connection system technology, applied to building components, building structures, walls, etc., can solve the problems of increased concrete construction wet work, poor seismic performance, poor reliability, etc., to achieve easy construction quality assurance, convenient construction, The effect of building speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In a preferred embodiment of the invention, the structure is used for beam-to-column connections.

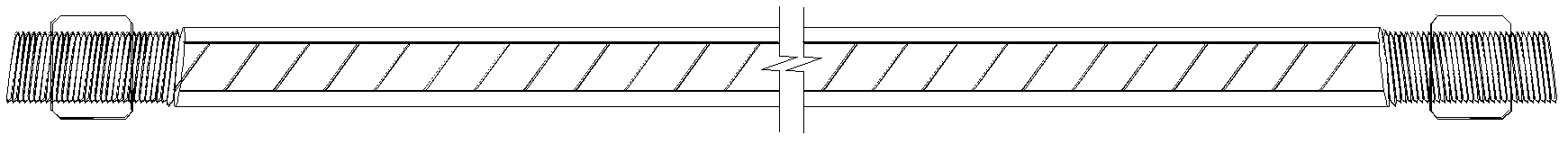

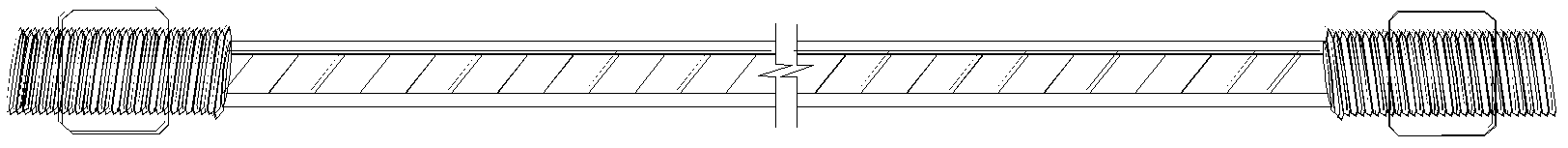

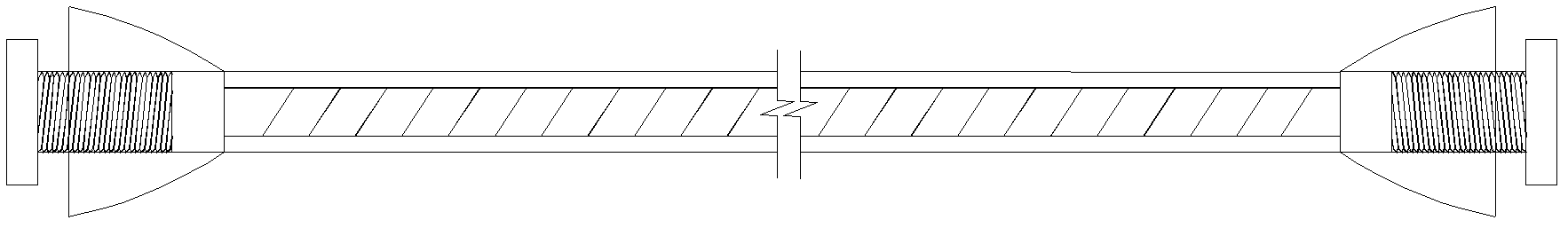

[0053] Such as Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 Shown: the prefabricated component 10 is produced and processed in the prefabrication factory with threaded steel bar 7 / 8 / 9 at the end. When pouring concrete, the threaded part at the end of the threaded steel bar 7 / 8 must be exposed, or ensure that the threaded steel bar at the end 9. The section of the end is kept flush with the prefabricated component 10, and the end sleeve of the threaded steel bar 9 is poured into the prefabricated component 10. The position of the threaded steel bar 7 / 8 / 9 at the end is respectively connected with the column belt straight stiffener single web connector ( Figure 4 ), single web connectors with oblique stiffeners ( Figure 5 ), wall double web connectors ( Image 6 ) corresponding to the positions of the screw holes 12, and the threaded ...

Embodiment 2

[0055] In a preferred embodiment of the invention, the structure is used for wall connection.

[0056] Such as Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 As shown, the embodiment of the wall connection of the present invention is: the prefabricated component 10 adopts the threaded steel bar 7 / 8 / 9 at the end to be produced and processed in the prefabrication plant. When pouring concrete, the threaded part at the end of the threaded steel bar 7 / 8 must be Expose, or ensure that the cross section of the end of the upsetting internally threaded steel bar 9 is kept flush with the prefabricated component 10 , and pour the sleeve of the end of the upset internally threaded steel bar 9 into the prefabricated component 10 . The positions of the threaded steel bars 7 / 8 / 9 at the end are respectively connected to the wall single web connectors ( Figure 7 ), single web connector with stiffened si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com