Pre-mixing type high-expansion foam generation device

A high-expansion foam and generating device technology, applied in fire rescue and other directions, can solve problems such as high requirements and liquefied natural gas cannot play a protective role, and achieve the effect of ensuring effectiveness and optimal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

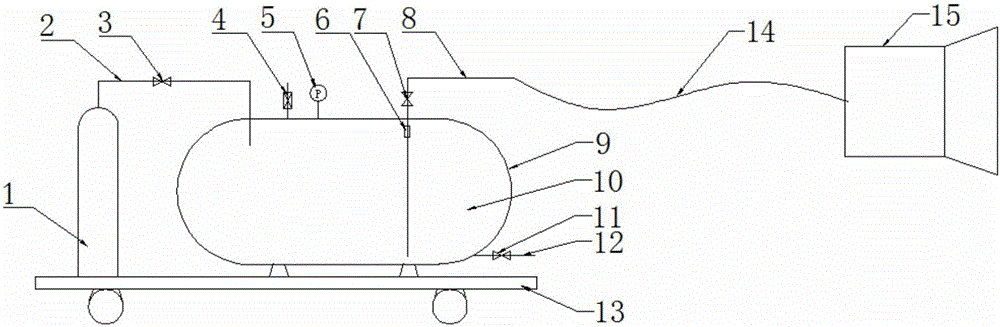

[0020] The invention provides a premixed high-expansion foam generating device, which includes a high-expansion foam generator, a high-expansion foam premix pressure tank and a compressed gas cylinder, and a premixed foam liquid is housed in the high-expansion foam premix pressure tank, through The high-pressure gas in the compressed gas cylinder makes the premixed foam liquid enter into the high-expansion foam generator to generate high-expansion foam.

[0021] The premixed high-expansion foam generating device also includes an air inlet pipe, a pressure reducing valve, a safety valve, a pressure gauge, a filter, a first switch valve, a liquid outlet pipe, a second switch valve, a flushing liquid discharge pipe and a fire hose .

[0022] A safety valve, a pressure gauge, a filter, a first switch valve, a liquid outlet pipe, and a flushing and draining pipe are installed on the high-expansion foam premixing pressure tank, and the flushing and draining pipes are installed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com