Fine particle rotational flow type electric agglomeration dust removing and collecting device

A fine particle and collection device technology, which is applied in the field of environmental engineering, can solve problems such as human body and environmental hazards, particle size that cannot meet the dust collection requirements, and fine particles that cannot fully collide, so as to improve dust removal efficiency, improve charging effect, The effect of increasing the particle concentration and the number of collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

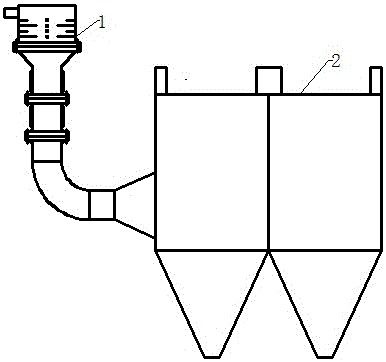

[0016] figure 1 It is a schematic diagram of a fine particle cyclone electrocoagulation and collection device. The electrocoagulation device 1 is located at the front end of the electrostatic precipitator 2. After the fine particles in the smoke are processed by the electrocoagulation device 1, the fine particles are aggregated into smaller particles. Large particles can be collected by electrostatic precipitator 2.

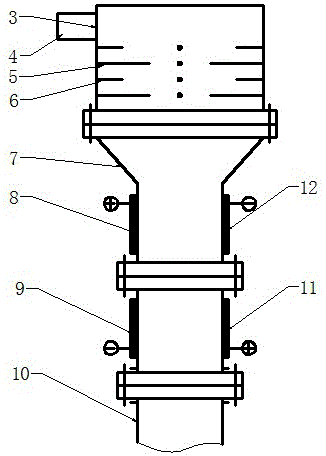

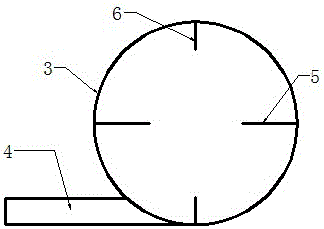

[0017] The electrocoagulation device 1 is installed at the feed port of the electrostatic precipitator 2, and the electrocoagulation device 1 includes a friction charging device and a coagulation device connected in sequence, and the coagulation device is connected with the electrostatic precipitator 1; the friction charging device It includes a shell 3, an airflow particle inlet 4, a prickly electrode 5 with a positive corona and a friction rod 6; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com