Combined type blanking female die and assembly method thereof

A combined and blanking technology, applied in the field of mold manufacturing, can solve problems such as mold failure, cracking at corners, complex structure, etc., and achieve the effect of simplifying design and manufacturing, prolonging service life, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and technical solution of the present invention more clear, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

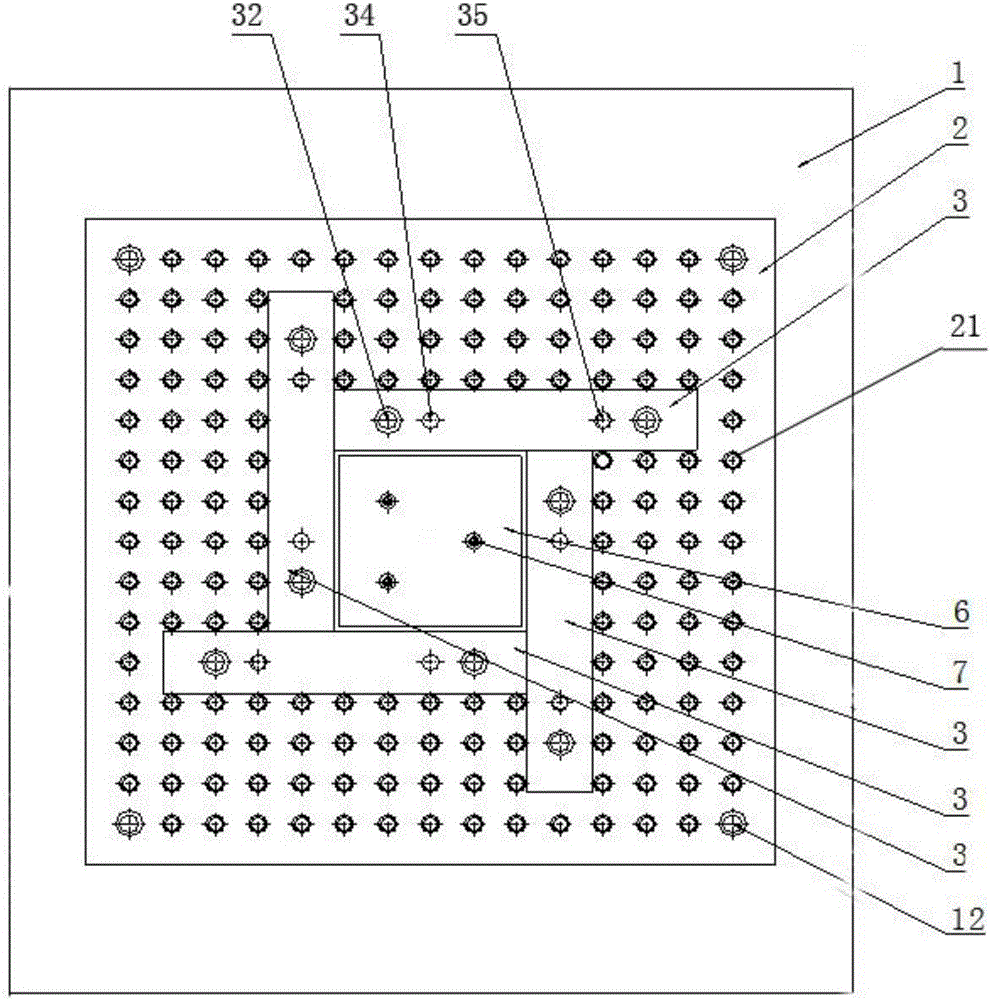

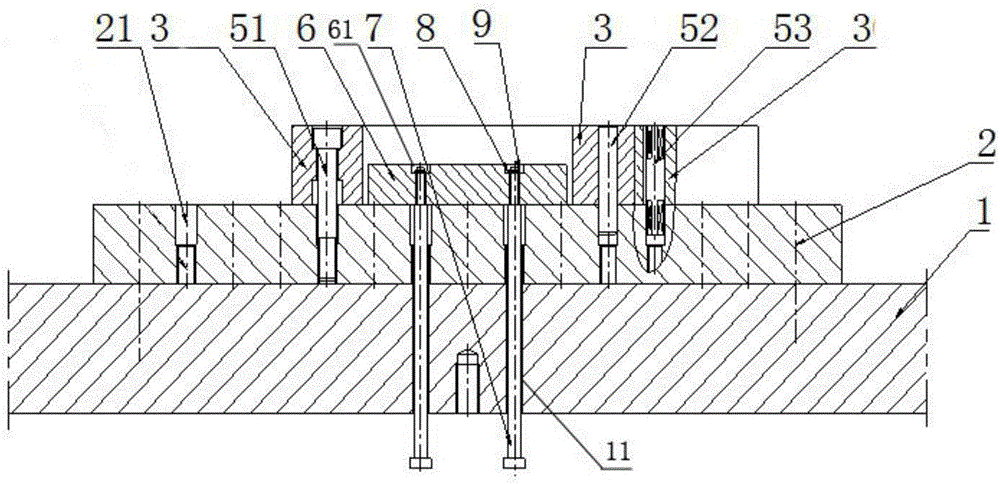

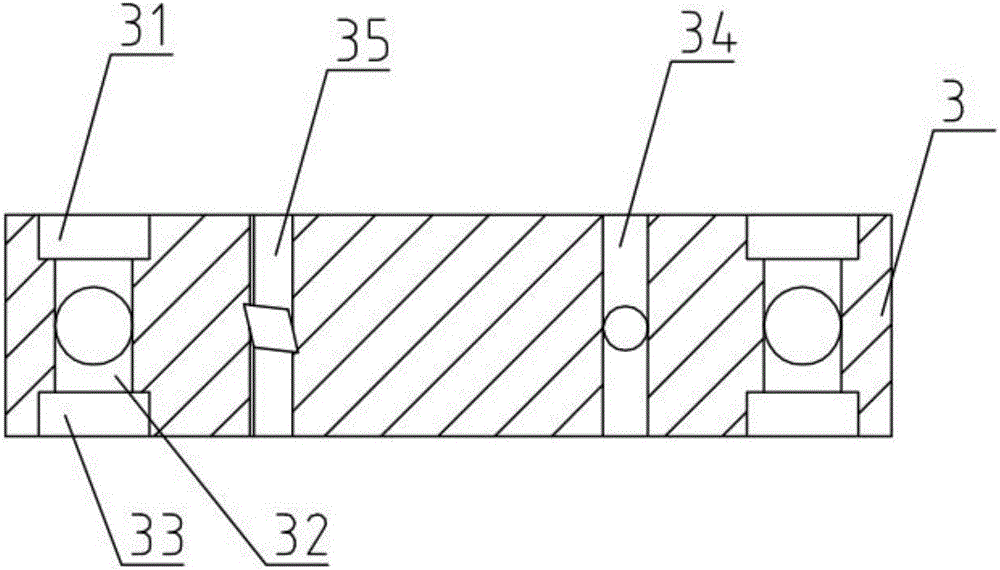

[0030] like figure 1 , figure 2 , image 3 and Figure 4 As shown, it is a combined blanking die of the present invention, which includes a die base 1 and a backing plate 2 installed on the die base 1 with several positioning threaded holes 21 at equal intervals on the plane, and also includes a base plate 2 arranged on the die base 1 Four rectangular parallelepiped modules 3 with a square cross-section on the upper plane of the backing plate 2, the four long edges of the module 3 are provided with cutting edges, and the modules 3 are arranged on any two mutually perpendicular planes along the direction of the four long edges. There are two countersunk head installation holes 32 which are mutually isolated and perpendicular to each other and symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com