Reflow soldering method of surface mount device type LED lamp reducing damage rate

A technology of reflow soldering and chip components, which is applied in the direction of welding equipment, printed circuits, electrical components, etc., can solve the problems of workpiece damage, uneven temperature, energy waste, etc., and achieve effective welding, rapid cooling temperature reduction, and accelerated cooling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

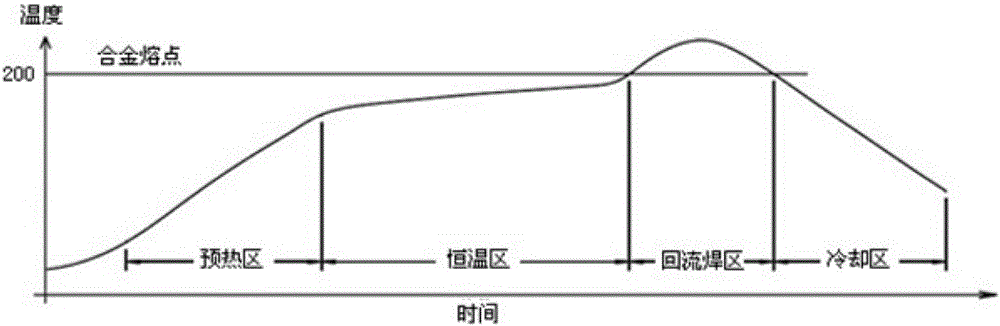

[0030] The working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as figure 1 As shown, a method for reflow soldering of chip components comprises the following steps:

[0032] Step 1. The temperature of the preheating zone is raised, and the temperature of the preheating zone is controlled to increase at a slope less than or equal to 4°C / s, and the temperature increases to 150°C to 200°C;

[0033] Step 2. Wet the solder paste in the constant temperature zone, and keep the temperature between 150°C and 200°C for 60 to 100 seconds until the solder paste is completely melted;

[0034] Step 3. Reflow soldering in the reflow area, control the temperature to rise to the peak temperature within 25-30 seconds, and keep the peak temperature ±5°C for no more than 10 seconds;

[0035] Step 4, cooling in the cooling zone, controlling the temperature to decrease at a slope of 6°C / s or less until the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com