A toothed roller and a pressure roller for stripping fiber crops

A technology of tooth grooves and roller teeth, applied in the field of agricultural equipment, can solve the problems of high processing cost, unfavorable industrialization promotion, limited stalk rolling pressure, etc., so as to reduce subsequent processing procedures and solve the problem of crushing bast fibers. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

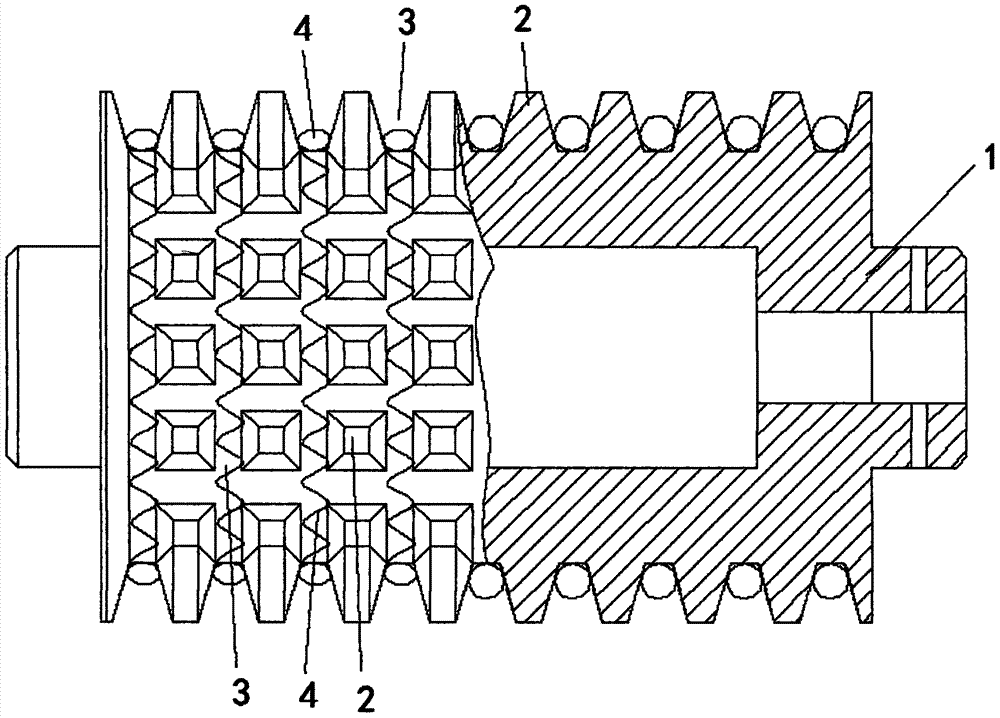

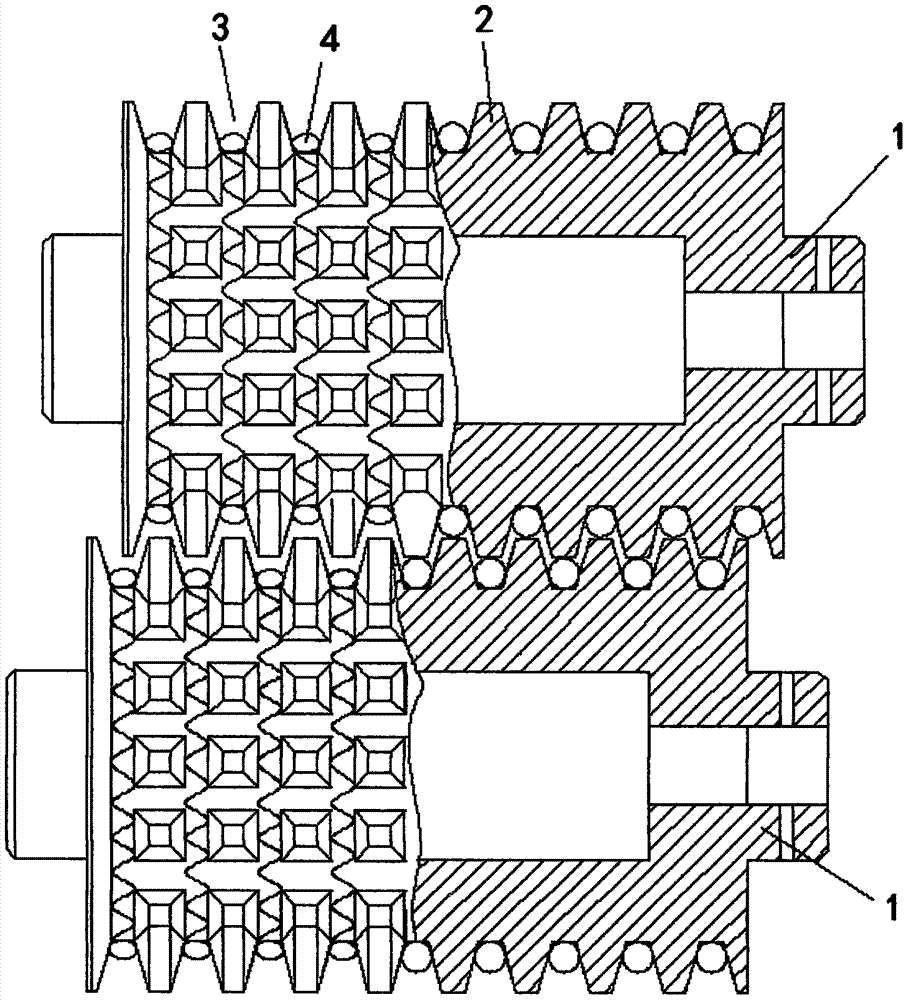

[0019] like figure 1 As shown, a toothed roller according to the present invention includes a roller shaft 1 and a plurality of roller teeth 2 arranged on the roller shaft 1, the top surface of the roller teeth 2 is a plane; In the circumferential direction, the roller teeth 2 are arranged around the surface of the roller shaft 1, and there is a gap between adjacent roller teeth 2; along the axial direction of the roller shaft 1, the roller teeth 2 are arranged side by side on the roller shaft 1 The surface of the roller shaft 1, and a gap is provided between adjacent roller teeth 2, and the gap continuously forms tooth grooves 3 in the circumferential direction of the roller shaft 1. Specifically, the bottom surface area of the roller tooth 2 is larger than the top surface area of the roller tooth 2, the bottom width of the toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com