An upper tooth plate adjustment device for an edge stripper for a stenter setting machine

The technology of a tenter setting machine and an adjusting device is applied in textile and papermaking, fabric surface trimming, fabric elongation and other directions, which can solve the problems of short service life, inconvenient installation, complicated fixing structure and the like, and achieve long service life, The effect of simple structure and shortened operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

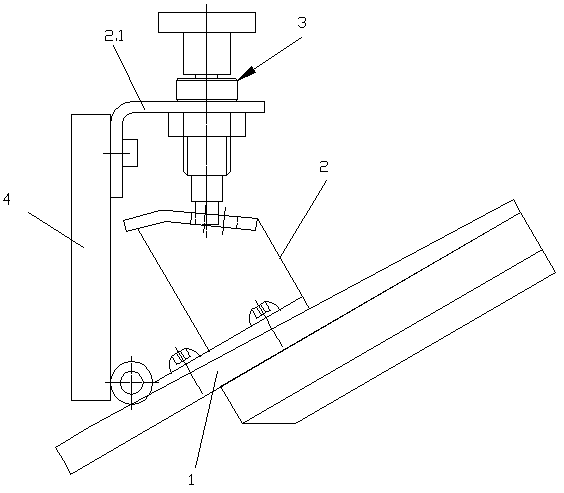

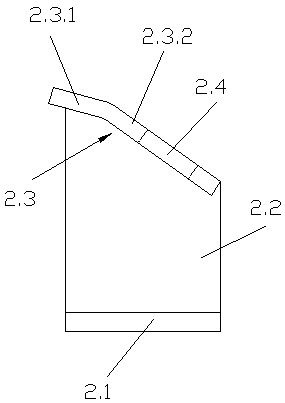

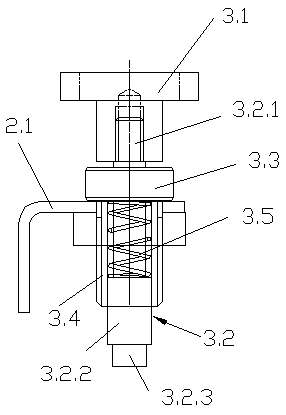

[0012] Embodiment 1: An upper tooth plate adjustment device of an edge stripper for a stenter setting machine, which is set on the upper tooth plate 1 of the edge stripper, including the buckle plate 2 on the upper surface of the upper tooth plate 1 and the top of the buckle plate 2 The bolt buckle assembly 3 and the vertical connecting plate 4 of the fixed bolt buckle assembly 3, the buckle plate 2 includes a horizontal plate 2.1 affixed to the upper surface of the upper tooth plate 1, and a vertical plate 2.2 vertically arranged with the horizontal plate 2.1 And the folded inclined plate 2.3 arranged on the top of the vertical plate 2.2, the folded inclined plate 2.3 is provided with a waist-shaped buckle hole 2.4; the bolt buckle assembly 3 includes a screw joint 3.1, a screw rod 3.2, a nut 3.3, a screw sleeve 3.4, the compression spring 3.5 and the horizontal connecting plate 5 vertically connected with the vertical connecting plate 4, the screwing sleeve 3.4 is vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com