Electric gate valve for controlling steam flow

A steam flow and flapper valve technology, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of remote automatic control of unfavorable steam flow, micro-leakage of high-pressure steam, etc., and achieve remote automatic control of steam flow, control Stable and reliable performance, convenient maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

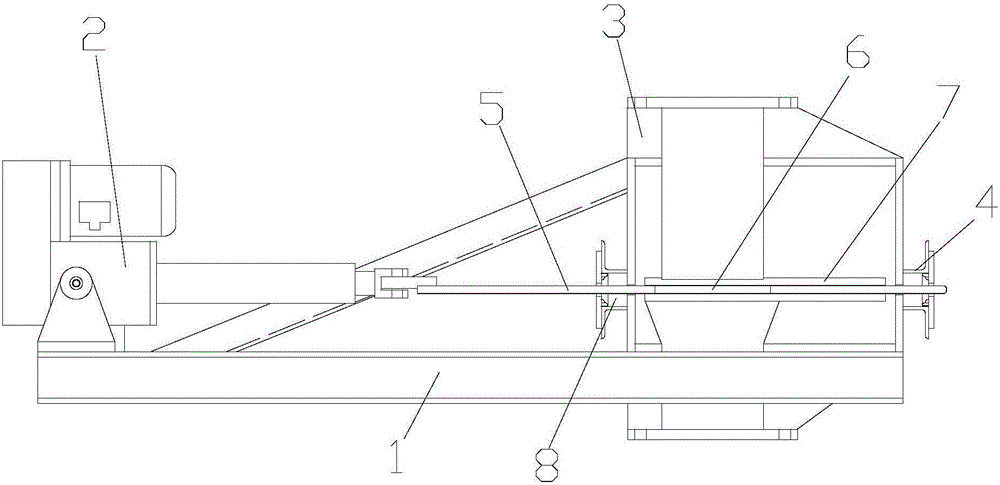

[0011] like figure 1 shown. The electric flapper valve for controlling steam flow includes a frame 1 made of channel steel, an electric push rod 2 is installed on the upper left end of the frame 1, and a box body 3 formed by welding steel plates is installed on the upper right end of the frame 1. 3 has a vertical chamber 31, the rod end of the electric push rod 2 on the frame 1 points to the box body 1 along the left and right directions, and the left and right side walls of the box body 1 are respectively provided with connecting pipes 4, and the left and right sides The connecting pipe 4 is located in the linear direction of the extension of the rod end of the electric push rod 2. Slideways are respectively arranged in the left side wall and the right side wall of the box body 3 along the linear direction of the extension of the rod end of the electric push rod 2, and the rod ends of the electric push rod 2 are connected. There is a horizontal board 5, and the board 5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com