Copper wire drawing machine for cable

A wire drawing machine and copper wire technology, which is applied in the field of copper wire wire drawing machines for cables, can solve the problems of broken copper wires and failure to shut down the machine in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

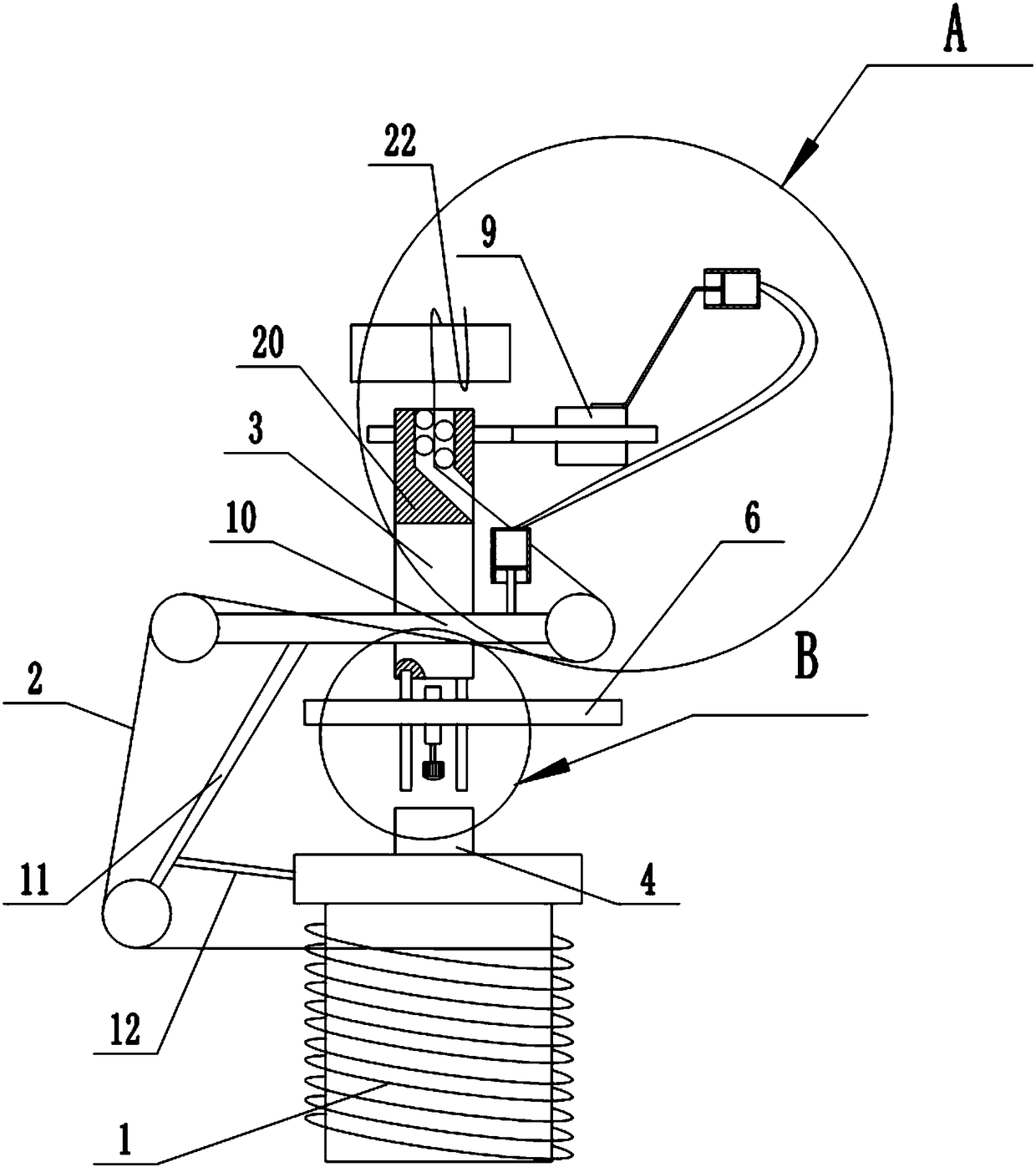

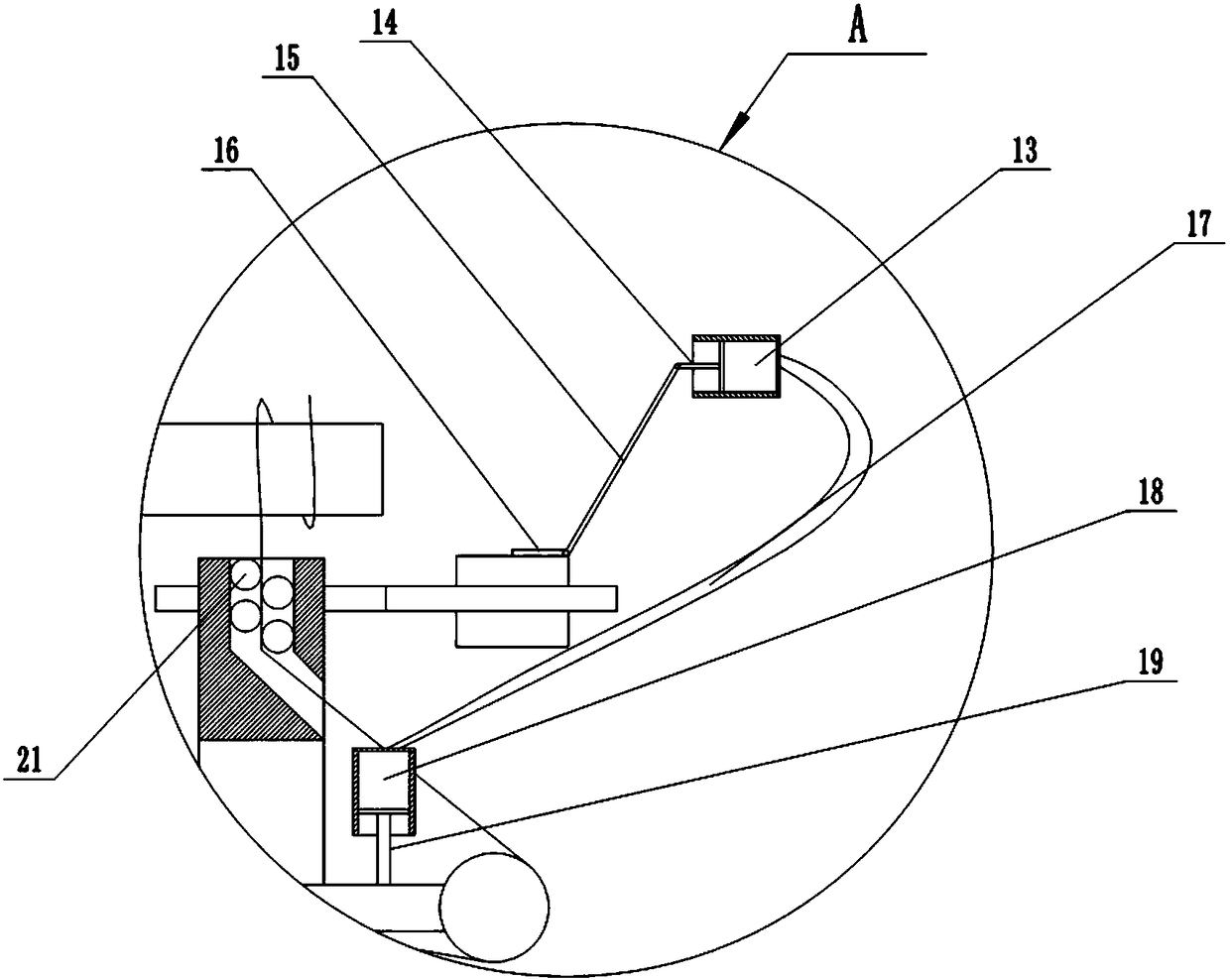

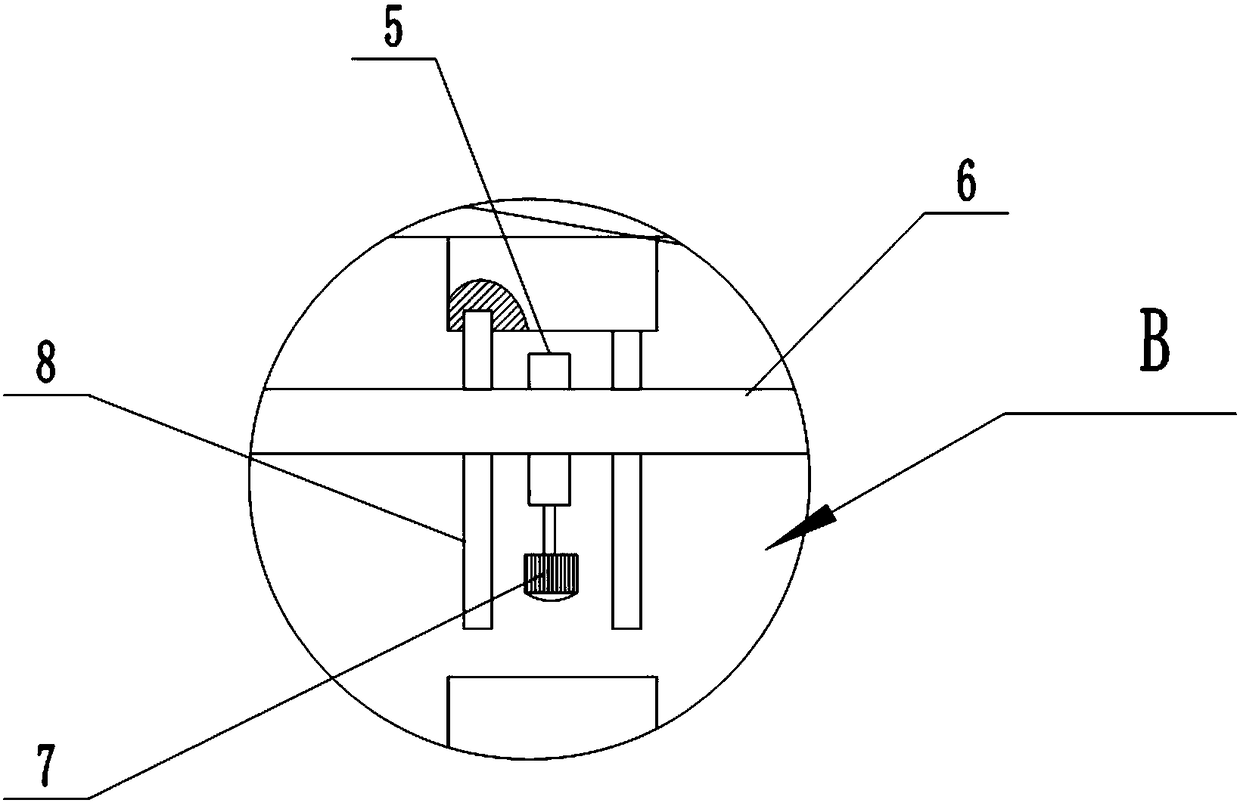

[0024] The reference signs in the drawings of the description include: pay-off drum 1, copper wire 2, first rotating shaft 3, second rotating shaft 4, third rotating shaft 5, adapter sleeve 6, first motor 7, bump 8, fourth rotating shaft 9. Tension rod 10, adjusting rod 11, slide rod 12, second piston barrel 13, second piston rod 14, first connecting rod 15, second connecting rod 16, pipeline 17, first piston barrel 18, first Piston rod 19, guide sleeve 20, pressure roller 21, reel 22.

[0025] Such as figure 1 As shown, the copper wire drawing machine for cables includes a frame. The lower end of the frame is rotatably connected with a pay-off barrel 1, and a one-way bearing is connected between the pay-off barrel 1 and the frame. The frame is located above the pay-off barrel 1. There are tensioning unit, drawing unit, heating unit, pulling unit and driving unit.

[0026] The dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com