Light path heat dissipating combination system for spotlight

A combination system and heat dissipation system technology, applied in the field of spotlight road heat dissipation combination system, can solve the problems of affecting the illumination effect of LED spotlights, affecting the illumination effect of spotlights, and the beam angle becomes relatively large, so as to achieve improved light efficiency, low cost, The effect of short manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

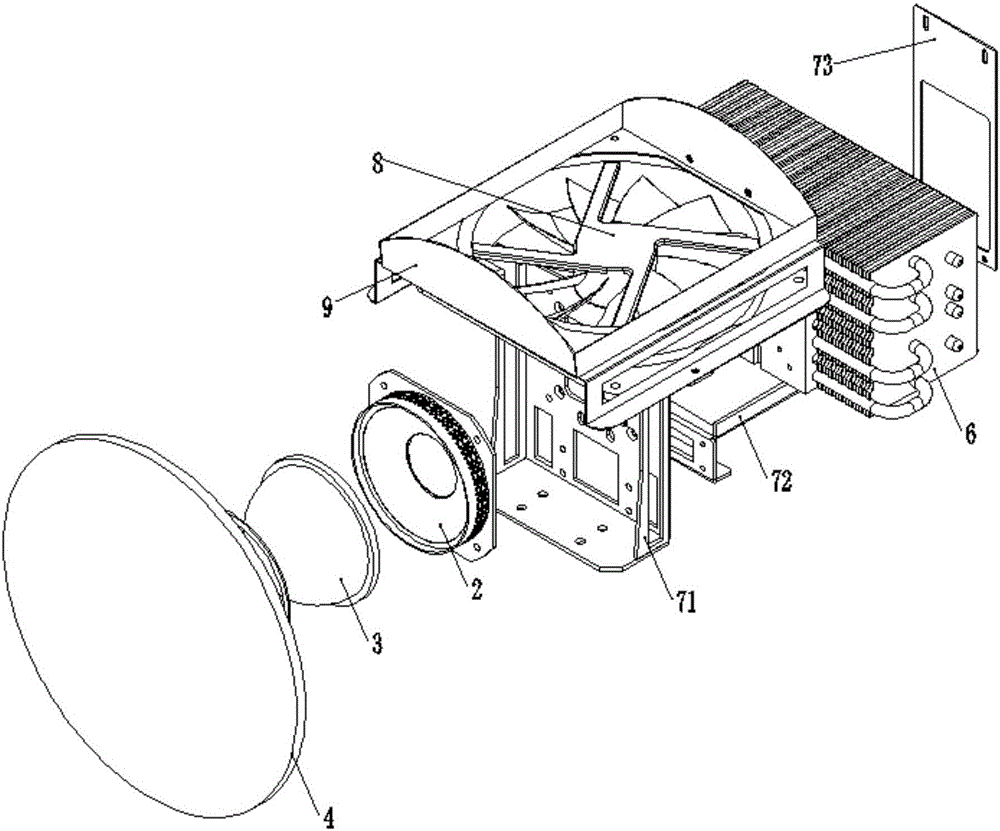

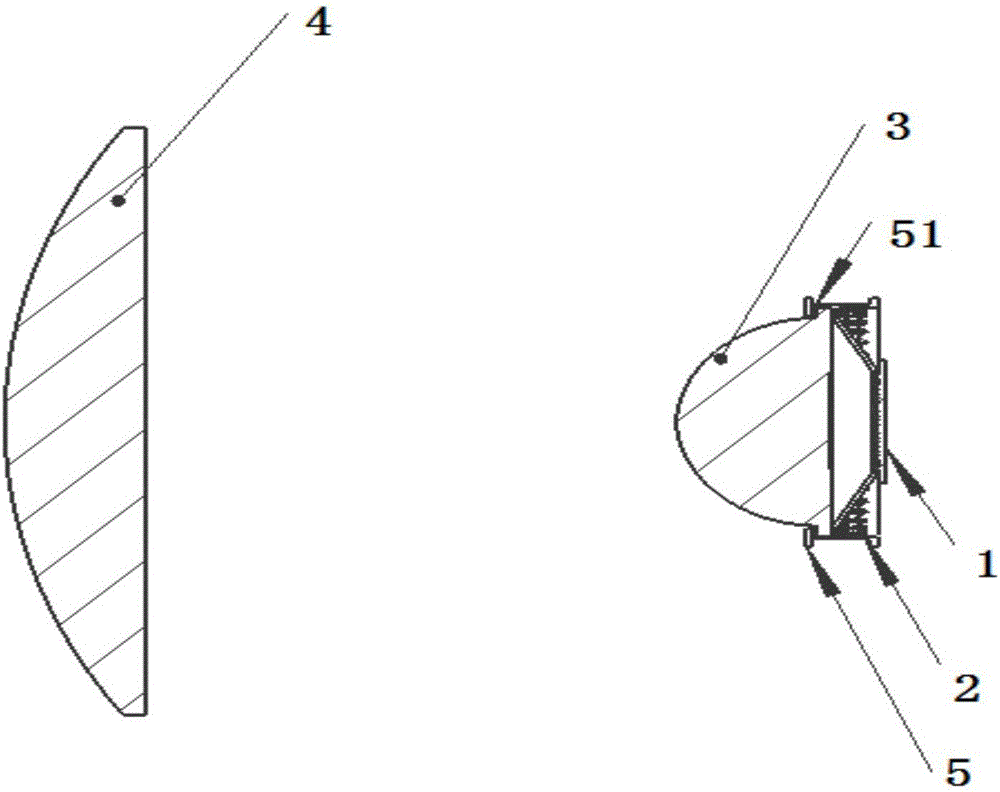

[0070] Such as Figure 1-7 As shown, this embodiment provides a spotlight path heat dissipation combined system, including an optical path system and a heat dissipation system, wherein:

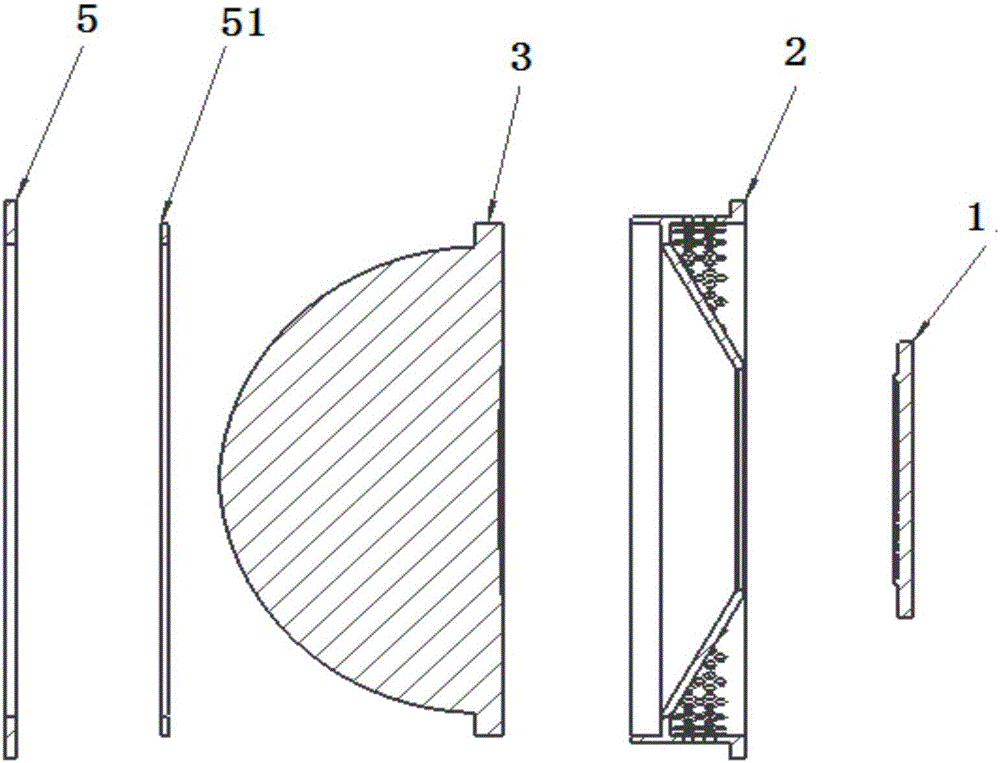

[0071] The optical path system includes: COB integrated light source 1, light receiver 2, aspheric mirror 3 (first-class lens), plano-convex mirror 4 (secondary lens);

[0072] Such as Figure 4 , 5 As shown, the light source light receiver 2 is a cylinder with openings at both ends, including a light inlet 201, a reflection part, and a light outlet 202. One end of the cylinder is the light outlet 202 of the light source receiver, and the end of the light outlet 202 is provided with a concave Enter the tapered surface 203 in the cylinder, the bottom of the tapered surface 203 forms an opening, which is the light inlet 201 of the light receiver, the end surface of the light inlet 201 is on the same level as the end surface of the other end of the cylinder, The tapered surface 203 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com