Front screen and touch screen testing tool

A touch screen testing and fixture technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as hidden quality risks, low test efficiency, problems, etc., to reduce labor costs and test costs, and improve test efficiency. , the effect of reducing the false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

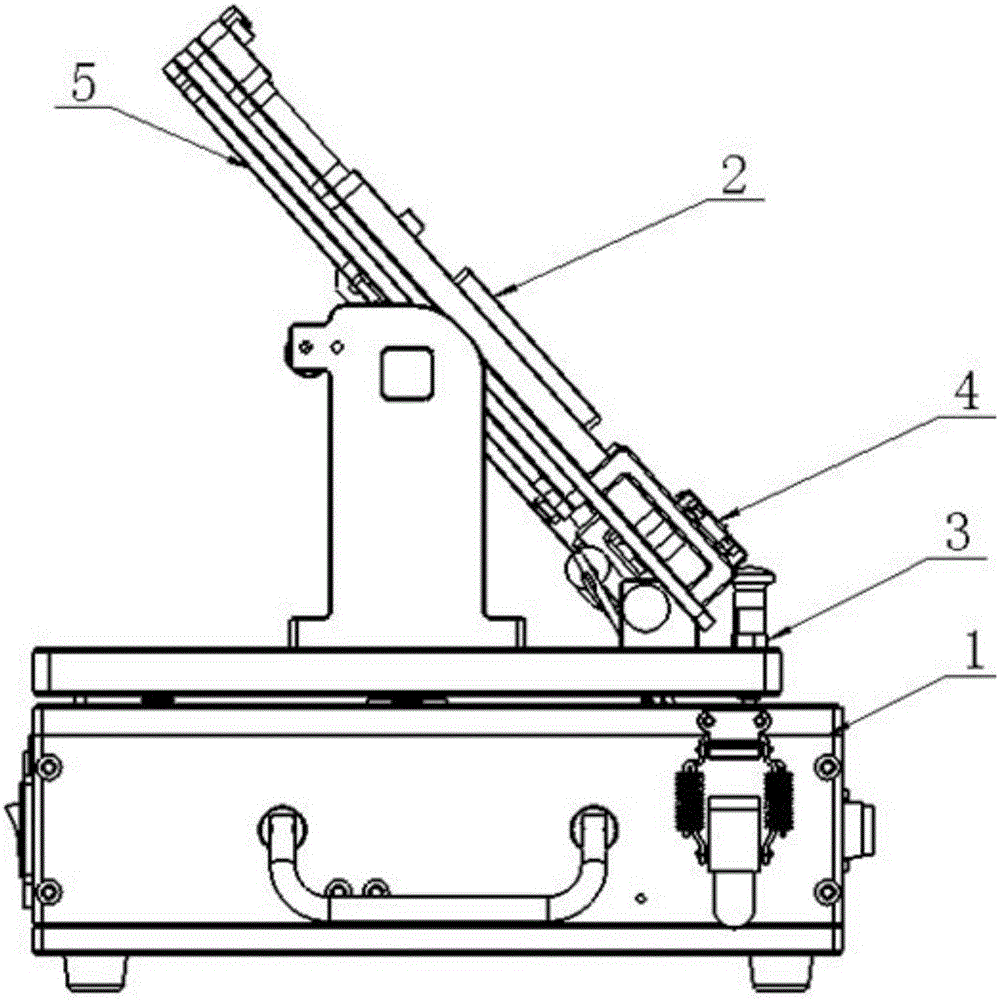

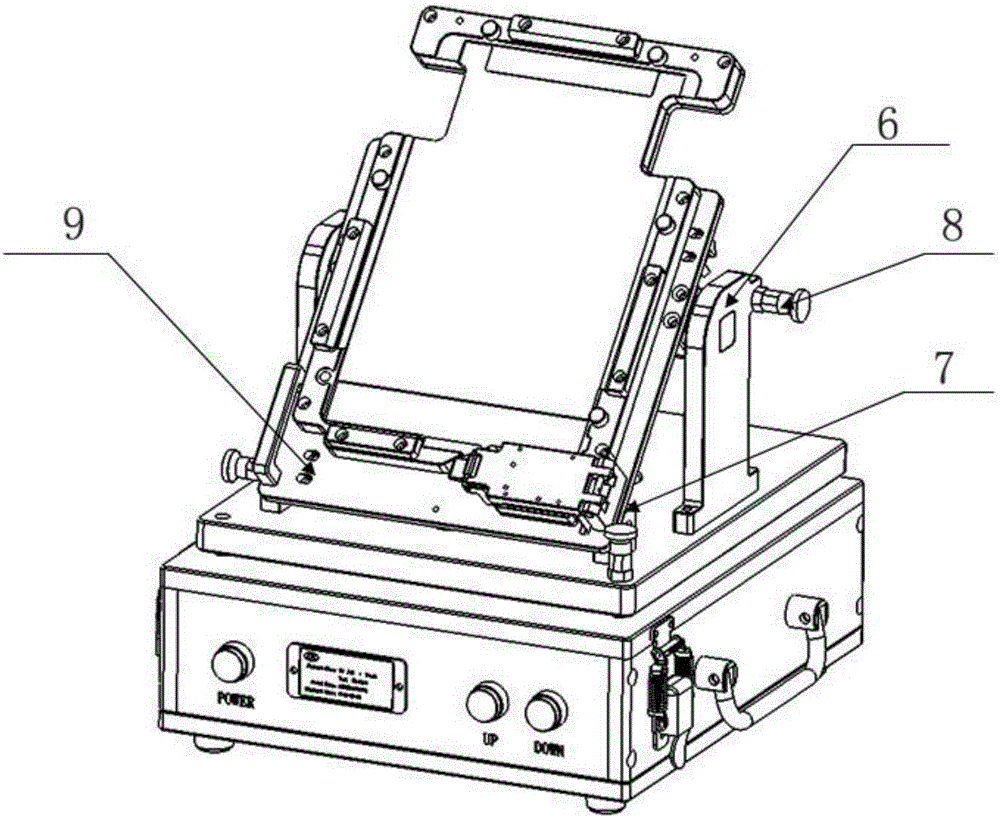

[0016] like Figure 1~2 As shown, a front screen and touch screen test fixture includes a bottom frame module 1, a pallet module 2, a turning module 3, a needle mold module 4 and a test main board 5, and the bottom frame module 1 is equipped with a turning Module 2, the turning module 2 is connected to the carrier 9, the movable pin 7 and the support seat 6 are fixedly installed on the turning module 3, a thrust bearing is arranged between the support seats 6, and one end of the carrier 9 is connected to the movable pin 7 , the other end is connected with the thrust bearing, the upper end of the carrier 9 is fixedly equipped with a pallet module 2, and a needle mold module 4 is arranged on one side of the pallet module 2, and the pallet module 2 and the needle mold module 4 are in phase In cooperation, a test main board 5 is installed on the bottom of the carrier 9 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com