Electrode subassembly alignment detection apparatus and detection method thereof

A technology of electrode components and detection devices, which is applied in the direction of electrical components, optical device exploration, non-aqueous electrolyte battery electrodes, etc., can solve the problems of low alignment efficiency, hinder the automatic production and manufacture of laminated batteries, and be prone to missed inspections, and achieve improved The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

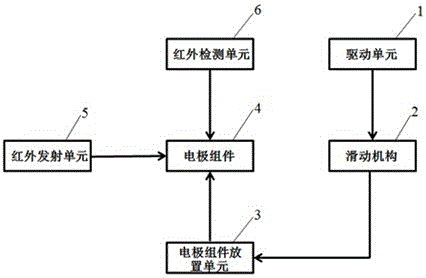

[0015] like figure 1 As shown, the electrode assembly alignment detection device described in this embodiment includes an electrode assembly placing unit 3 , a sliding mechanism 2 , a driving unit 1 , an infrared emitting unit 5 and an infrared detecting unit 6 . The electrode assembly placement unit 3 is used to place and fix the electrode assembly 4, and the placement unit can transmit infrared signals. The sliding mechanism 2 is used to drive the electrode assembly placing unit 3 close to the infrared emitting unit 5 . The drive unit 1 is used to slide the sliding mechanism 2 . The infrared emitting unit 5 is used for emitting infrared signals. The infrared detection unit 6 is used to detect infrared signals to detect whether the electrode assemblies are neatly arranged. The infrared emitting unit 5 emits an infrared signal. If the electrode assembly 4 is not aligned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com