Method for detecting cannabinoid in industrial hemp floral leaves and extracts thereof by high performance liquid chromatography

A high-performance liquid chromatography and extraction technology, which is applied in the field of high-performance liquid chromatography detection of cannabinoids in industrial hemp flowers and leaves and their extracts, can solve the problem of inaccurate detection of cannabinoid content, high requirements for operators, and high content Low detection results and other problems, to achieve the effect of simple and convenient detection method, accurate detection results and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

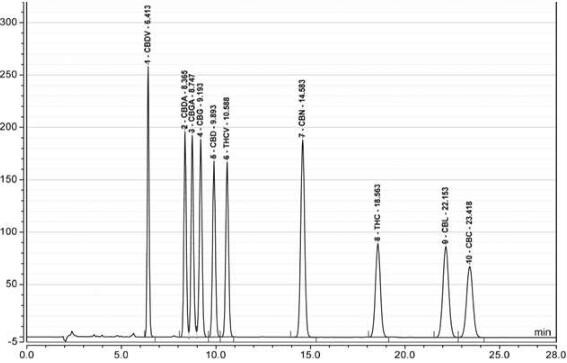

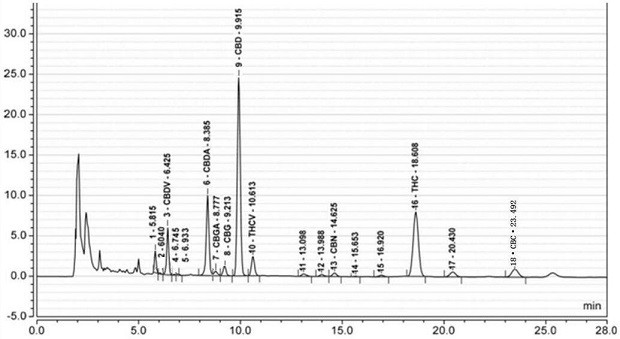

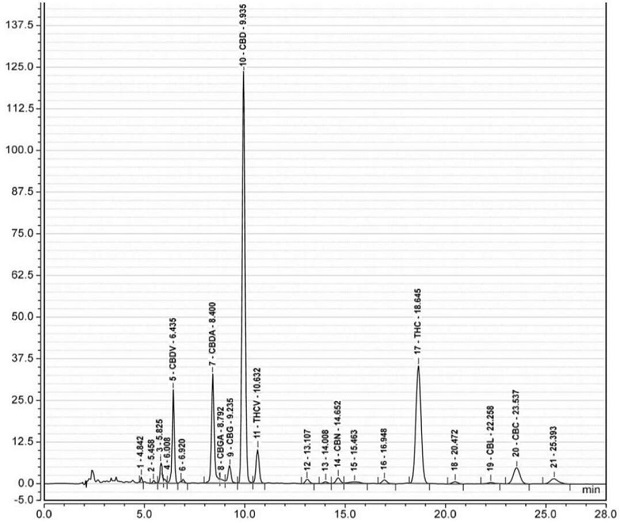

Image

Examples

Embodiment 1

[0031] The method for the high performance liquid chromatography detection industrial hemp mosaic leaf described in present embodiment 1, comprises the following steps:

[0032]①Preparation of flower leaf extract leaves: first place the cannabis flower leaves in an oven for baking, the baking conditions of the cannabis flower leaves are: continuous baking at 100°C for 1 hour, and then the roasted cannabis flower leaves Send it into the pulverizer and crush it into flower leaf powder. The crushed particle size of the flower leaf powder is 10 mesh. The industrial hemp flower leaves are fresh flower leaves, dried flower leaves and extracted flower leaf residues, and then accurately weigh the flower leaves The powder is placed in an Erlenmeyer flask with a ground mouth, and the first extraction solvent is added to the beaker. The first extraction solvent is analytically pure methanol, and the mass ratio of the first extraction solvent to the flower leaf powder is 1:90, and then the...

Embodiment 2

[0040] The method for the high performance liquid chromatography detection industrial hemp mosaic leaf described in present embodiment 2, comprises the following steps:

[0041] ①Preparation of flower leaf extract leaves: first place the cannabis flower leaves in an oven for baking, the baking conditions of the cannabis flower leaves are: continuous baking at 120°C for 2 hours, and then the roasted cannabis flower leaves Send it into the pulverizer and crush it into flower leaf powder. The crushed particle size of the flower leaf powder is 50 mesh. The industrial hemp flower leaves are fresh flower leaves, dried flower leaves and extracted flower leaf residues, and then accurately weigh the flower leaves The powder is placed in a Erlenmeyer flask with a ground mouth, and the first extraction solvent is added to the beaker. The first extraction solvent is analytical pure methanol, superior grade pure methanol or chromatographically pure methanol. The mass ratio of the first extr...

Embodiment 3

[0049] The method for the high performance liquid chromatography detection industrial hemp mosaic leaf described in present embodiment 3, comprises the following steps:

[0050] ①Preparation of flower leaf extract leaves: first place the cannabis flower leaves in an oven for baking, the baking conditions of the cannabis flower leaves are: continuous baking at 140°C for 3 hours, and then the roasted cannabis flower leaves Send it into the pulverizer and crush it into flower leaf powder. The crushed particle size of the flower leaf powder is 80 mesh. The industrial hemp flower leaves are fresh flower leaves, dried flower leaves and extracted flower leaf residues, and then accurately weigh the flower leaves The powder is placed in a Erlenmeyer flask with a ground mouth, and the first extraction solvent is added to the beaker. The first extraction solvent is analytical pure methanol, superior grade pure methanol or chromatographically pure methanol. The mass ratio of the first extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com