Heated whole egg liquid and its manufacturing method

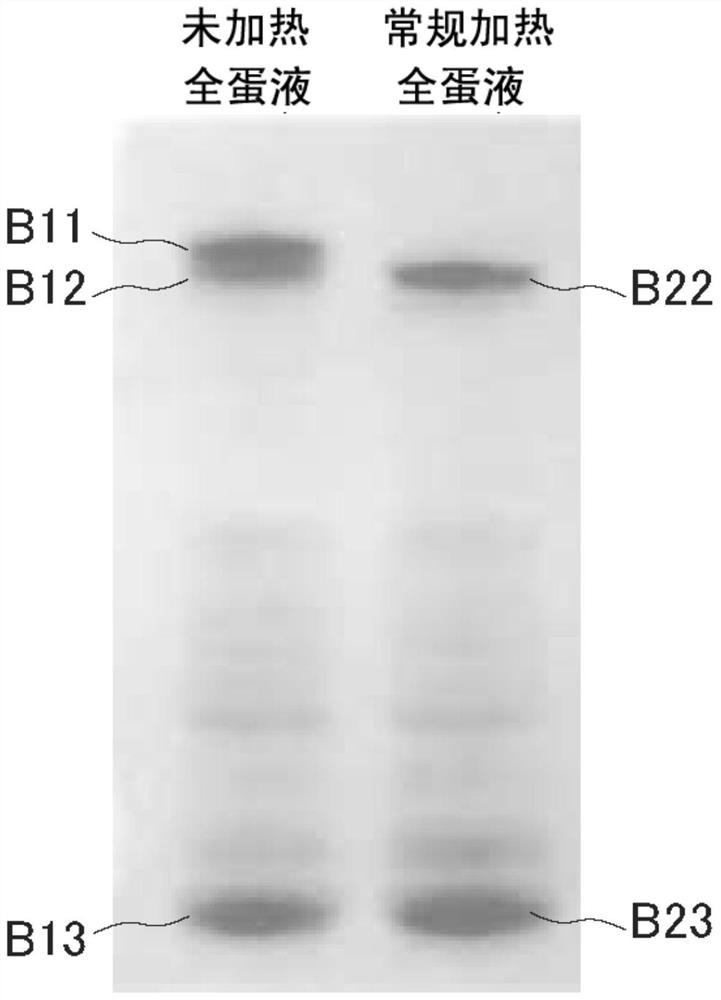

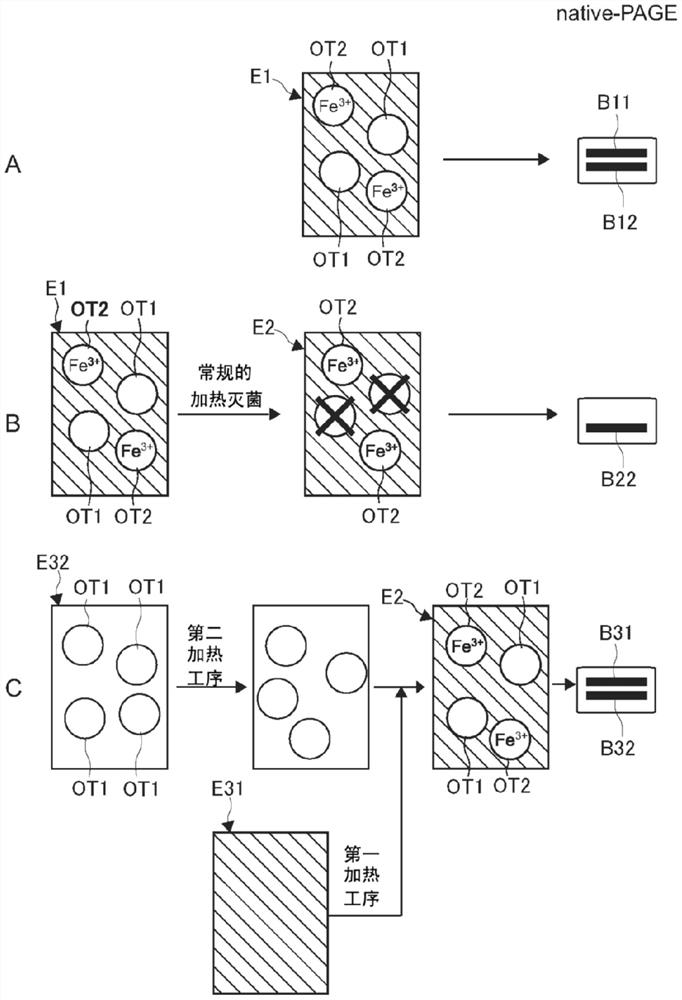

A technology of whole egg liquid and transferrin is applied in the field of heating whole egg liquid, which can solve the problems of reduced taste, reduced product volume, and delayed foaming time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

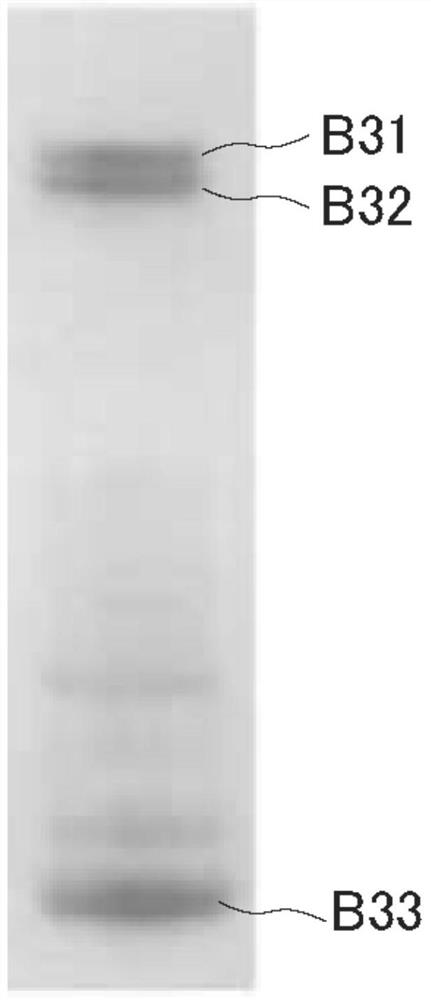

Embodiment 1~6

[0107] Break the shell eggs mechanically, separate the egg yolk liquid from the egg white liquid, and filter them by normal methods. In the following steps, a continuous heat exchanger (manufactured by Iwai Machinery Co., Ltd.) was used. First, as the first heating step, the obtained liquid egg yolk was heated to 61° C. as shown in Table 1, kept for about 3.5 minutes, and then cooled to 5° C.. It should be noted that the egg yolk liquid in this embodiment contains 17% egg white liquid. Next, as a second heating step, the separated egg white liquids were heated under the temperature conditions shown in Table 1, respectively. Next, the heated egg yolk liquid and egg white liquid were mixed, and homogenized using a propeller mixer to obtain whole egg liquid. Finally, the obtained whole egg liquid was cooled to below 8° C., and kept for the time shown in Table 1 respectively. Thus, the heated whole egg liquid of Examples 1-6 was obtained.

[0108] [Table 1]

[0109]

Embodiment 7

[0111] Break the shell eggs mechanically, separate the egg yolk liquid from the egg white liquid, and filter them by normal methods. Next, as the first heating step, the obtained liquid egg yolk was heated to 61° C., kept for about 3.5 minutes, and then cooled to 50° C.. Next, as a second heating step, the cooled egg yolk liquid and the egg white liquid separated from the egg yolk liquid were mixed, homogenized using a propeller mixer, heated to 56° C., and kept for 3.5 minutes. Finally, the obtained whole egg liquid was cooled to below 8°C and kept for 48 hours. Thus, the heated whole egg liquid of Example 7 was obtained.

Embodiment 8

[0113] The heated whole egg liquid of Example 8 was obtained by the method similar to Example 1 except having heated at 65 degreeC for 3.5 minutes in the 1st heating process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com