Coke dry quenching novel efficient primary dust collector

A dust collector and CDQ technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as boiler hanging pipe burst, affecting CDQ production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

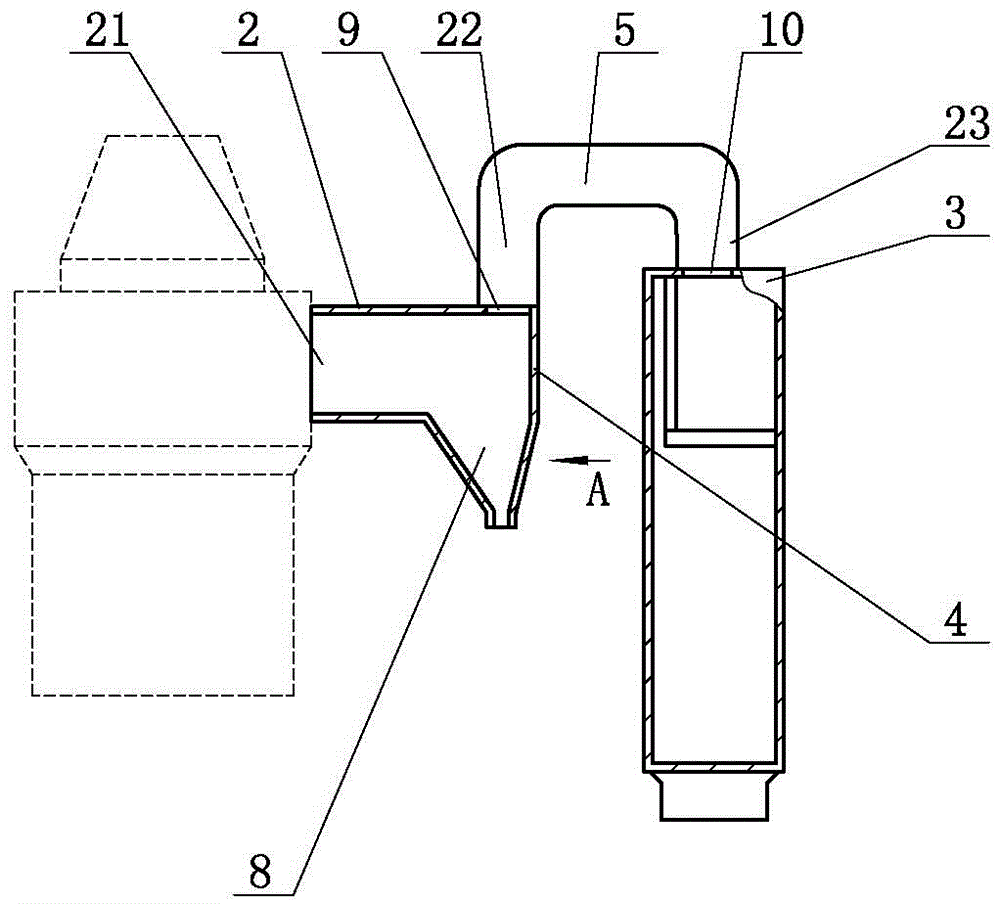

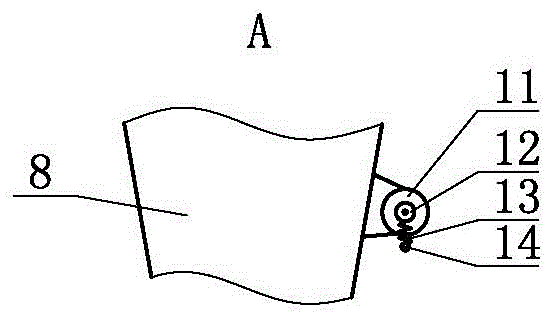

[0008] A new high-efficiency primary dust collector for coke CDQ described in the present invention comprises a primary dust collector housing 2, an air inlet 21 is arranged at one end of the primary dust collector housing 2, an ash hopper 8 is arranged at the bottom of the primary dust collector housing 2, and the ash hopper 8 The primary dust collector housing 2 on the side away from the air inlet 21 is provided with a primary dust collector rear wall 4, and an air outlet 9 is provided on the primary dust collector housing 2 at the top of the primary dust collector rear wall 4. The rear wall 4 of the primary dust collector can change the flow direction of the flue gas at the gas outlet of the primary dust collector, avoiding the flue gas from directly washing the boiler hanging pipe, and at the same time facilitating the heat exchange between the flue gas and the furnace tube of the secondary superheater. The flue gas passes through the rear wall of the primary dust collector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com