Finned tube heat exchanger and refrigeration cycle device equipped with it

A heat exchanger and finned tube technology, applied in the field of refrigeration cycle devices, can solve the problems of damaged heat exchange efficiency, damaged heating capacity, and increased thermal resistance, so as to suppress the increase of ventilation resistance and prevent unsatisfactory Uniform frosting and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

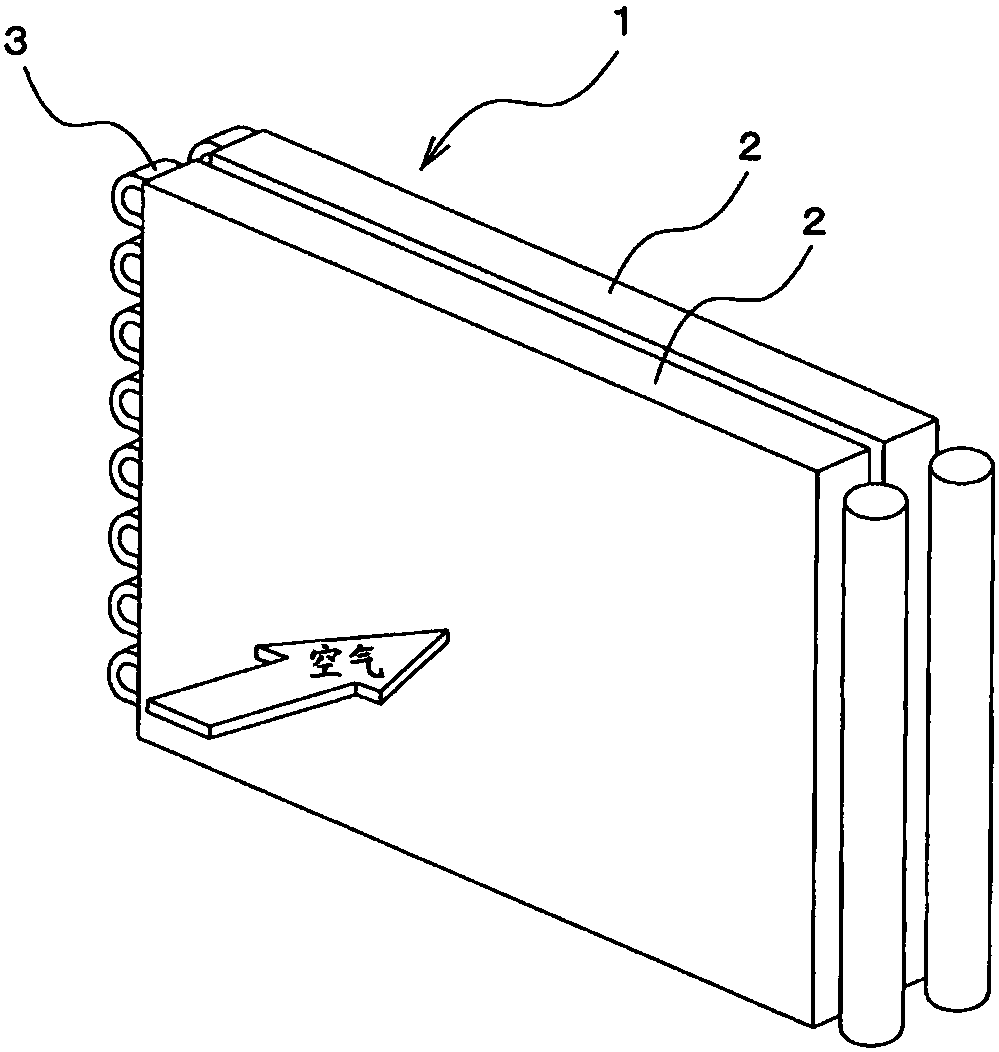

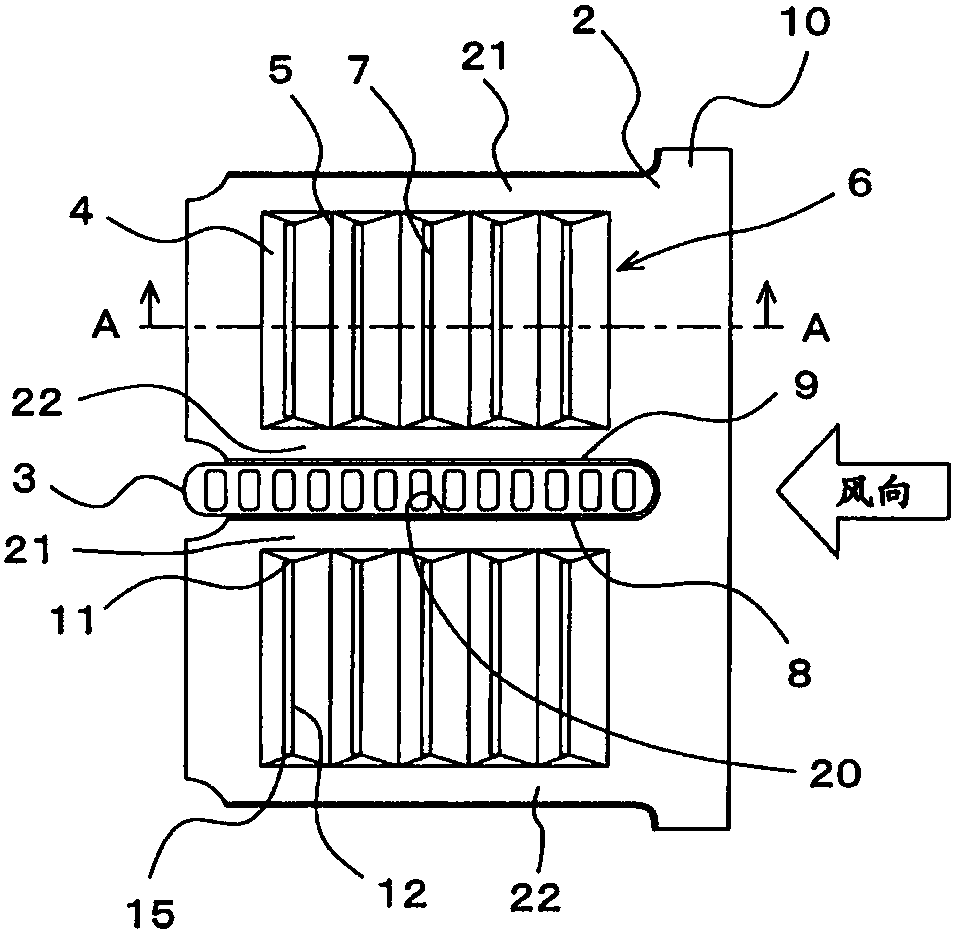

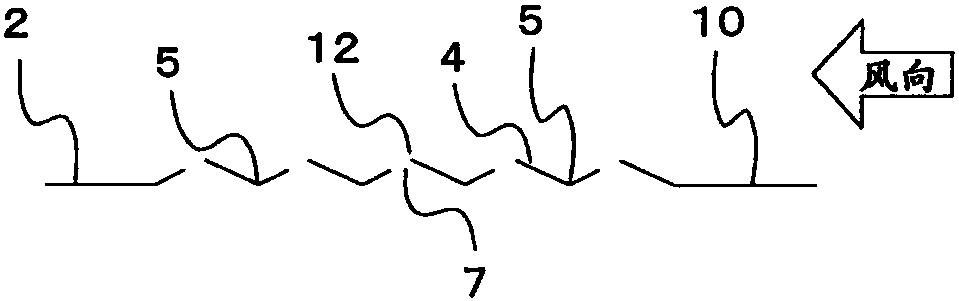

[0026] figure 1 It is a perspective view of the fin-tube heat exchanger according to Embodiment 1 of the present invention. figure 2 is showing figure 1 A plan view of the flat tube penetration portion of the plate fin used in the finned tube heat exchanger. image 3 yes figure 2 A-A line to see the cross-sectional view.

[0027] Such as Figure 1 ~ Figure 3 As shown, the finned tube heat exchanger (hereinafter, simply referred to as "heat exchanger") 1 according to the first embodiment has a plurality of rectangular plate-shaped fins 2 arranged in parallel, and gas flows between them. and a heat transfer tube (hereinafter referred to as "flat tube") 3 with a flat cross-sectional shape, which is inserted into the cutout portion 20 of the above-mentioned plate-shaped fin 2 at right angles and along the length of the plate-shaped fin 2 Multiple layers are provided in the side direction (=layer direction), and the working fluid passes through the inside of the heat transfe...

Embodiment approach 2

[0044] Figure 4 It is a perspective view showing the flat tube penetration portion of the plate-shaped fin used in the fin-tube heat exchanger according to Embodiment 2 of the present invention. Figure 5 It is a plan view showing the flat tube penetration portion of the plate-shaped fin used in the fin-tube heat exchanger according to Embodiment 2 of the present invention. Figure 6 is shown from Figure 4 A side view of the flat tube penetration portion of the plate-shaped fin viewed from the direction of line BB in . In addition, the same code|symbol is attached|subjected to the part corresponding to Embodiment 1 mentioned above in each figure. In addition, refer to the aforementioned figure 1 .

[0045] Such as Figure 4 ~ Figure 6 As shown, in the heat exchanger 1 which is a finned tube heat exchanger according to Embodiment 2 of the present invention, in order to secure the gap between adjacent plate-shaped fins 2 , that is, the fin pitch (FP) , the plate-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com