Pressure pulse test hydraulic pressure system for rubber hose test

A pressure pulse, hydraulic system technology, applied in the direction of fluid pressure actuation system components, the use of repetitive force/pulse force test material strength, fluid pressure actuation device, etc., can solve the hydraulic cylinder impact force rubber hose curve instability and other problems, to achieve the effect of improving the performance and stability of high-voltage pulses, extending the service life and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific embodiment of the invention will be described below in conjunction with the accompanying drawings.

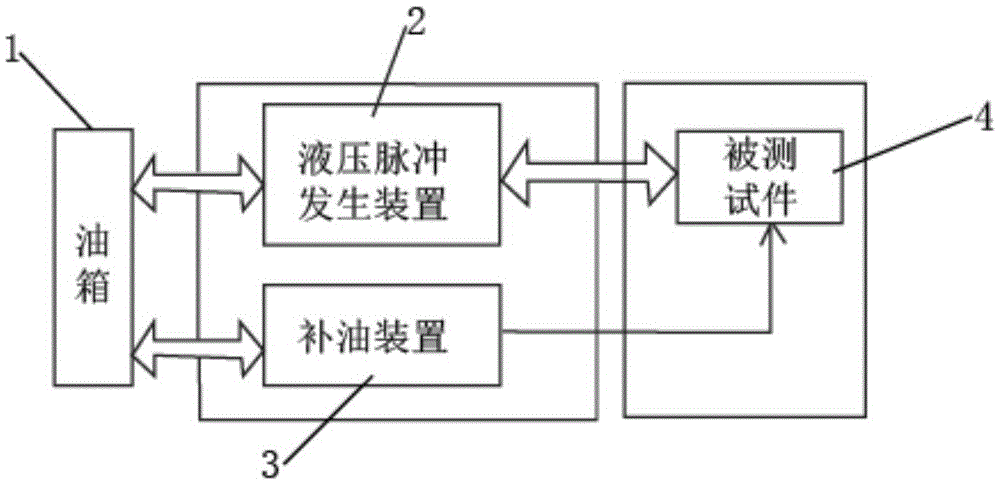

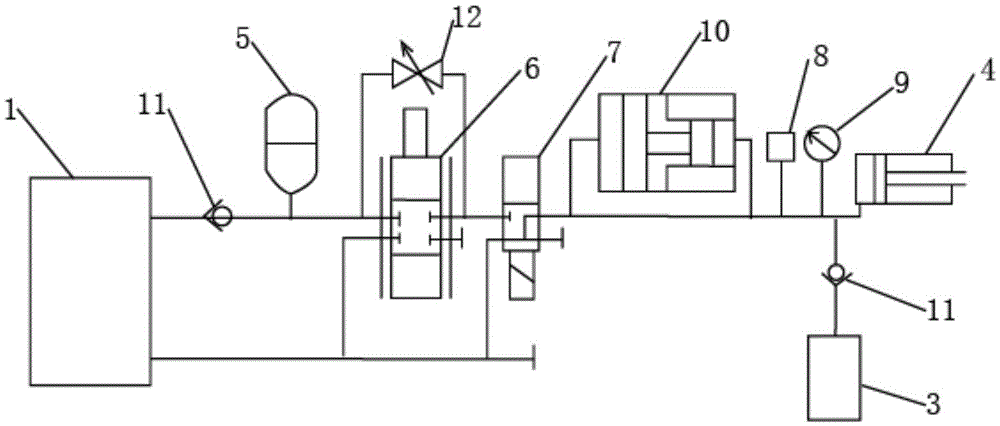

[0017] Such as figure 1 , figure 2 As shown, the present invention provides a pressure pulse test hydraulic system for rubber hose detection, which is characterized in that it includes a fuel tank 1, a hydraulic pulse generating device 2, an oil replenishing device 3, and a test piece 4. The hydraulic pulse generating device 2. The oil replenishment device 3 is set on the installation base, and the test piece 4 is installed on the bracket. The oil supply port and the oil return port of the fuel tank 1 are respectively connected with the oil supply port and the oil return port of the hydraulic pulse generating device 2, and the oil supply pipe inlet of the oil replenishment device 3 is connected with the oil supply port of the fuel tank 1 connected, the hydraulic pulse generator 2 is directly connected to the object under test 4 .

[0018] The hydraulic pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com