Fiber loose sleeve bulge detection apparatus

A detection device and optical fiber loose technology, which is applied in the field of optical fiber and cable, can solve the problems of reducing the production efficiency of the molding process, and achieve the effect of reducing processing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

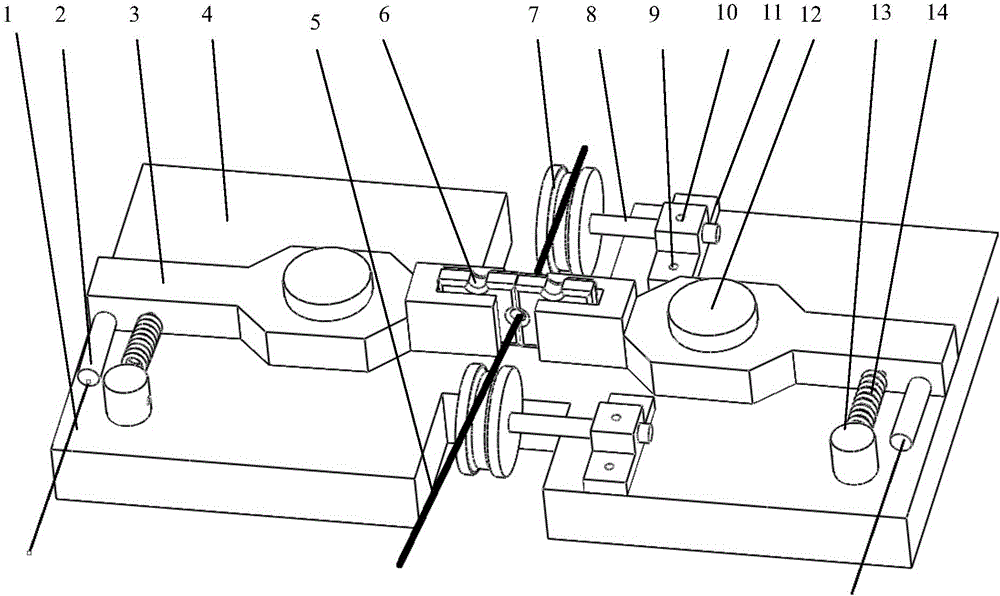

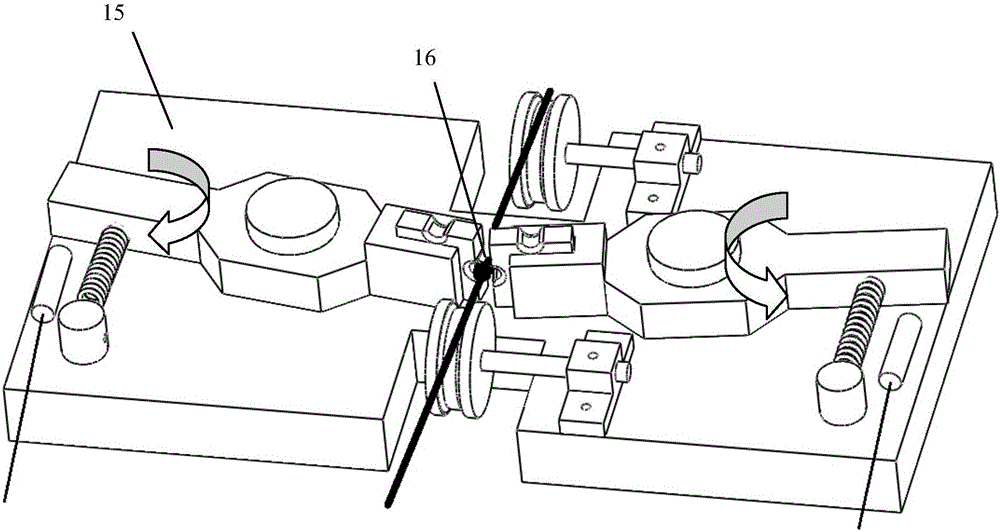

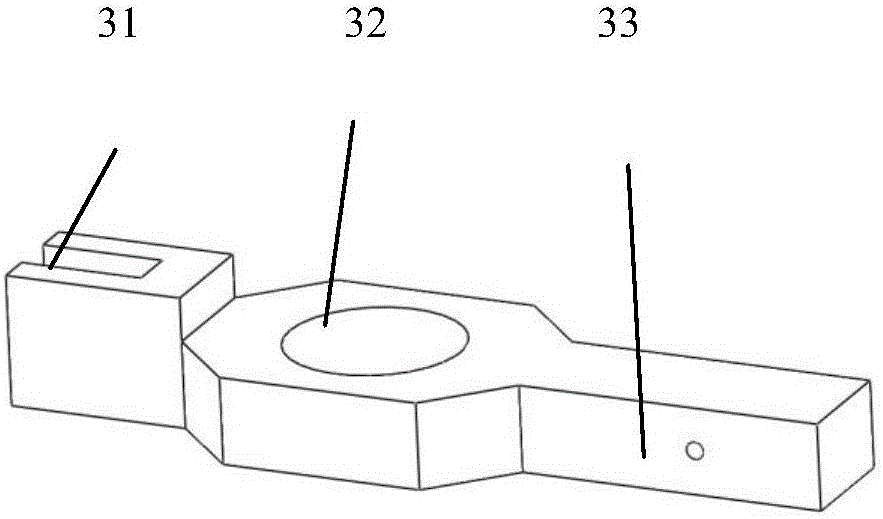

[0024] Such as figure 1 As shown, it is a structural diagram of the fiber loose tube bulge detection device, including the detection device base 4, and a pair of rotating arms 3 symmetrically distributed on the detection device base 4, and the rotating arm 3 is fixed on the detection device base 4 through the rotating shaft 12 Above, the rotating arm 3 can move around the rotating shaft 12 . A line-passing die 6 is clamped between the opposite ends of the rotating arm 3, wherein the line-passing die and the rotating shaft are both left and right, and have a symmetrical structure. The other end of rotating arm 3 links to each other with spring and base fixing device 13 respectively by telescopic spring 14; The sensing device control line 1 is connected with the main engine; the wire p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap