Ventilation and heat-dissipation structure of electric vehicle in-wheel motor

A hub motor and electric vehicle technology, applied to electric vehicles, motors, electric components, etc., can solve the problem that the air-cooled heat dissipation structure cannot meet the sealing requirements, and achieve good forced ventilation heat dissipation effect, taking into account compactness and manufacturing costs Economical and safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

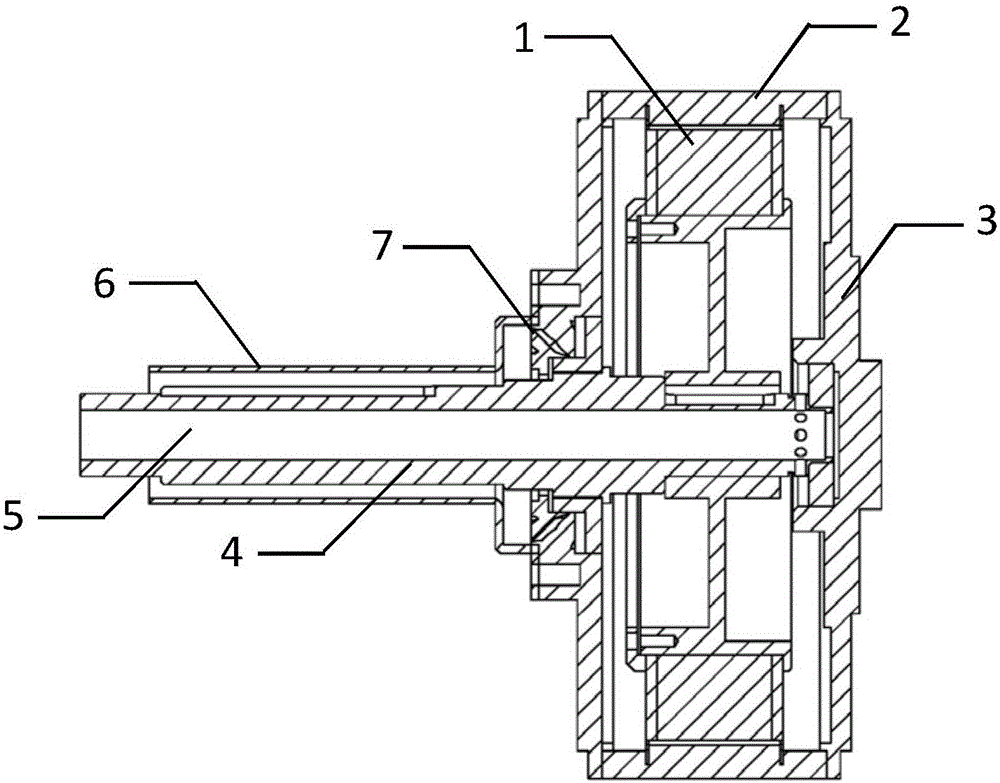

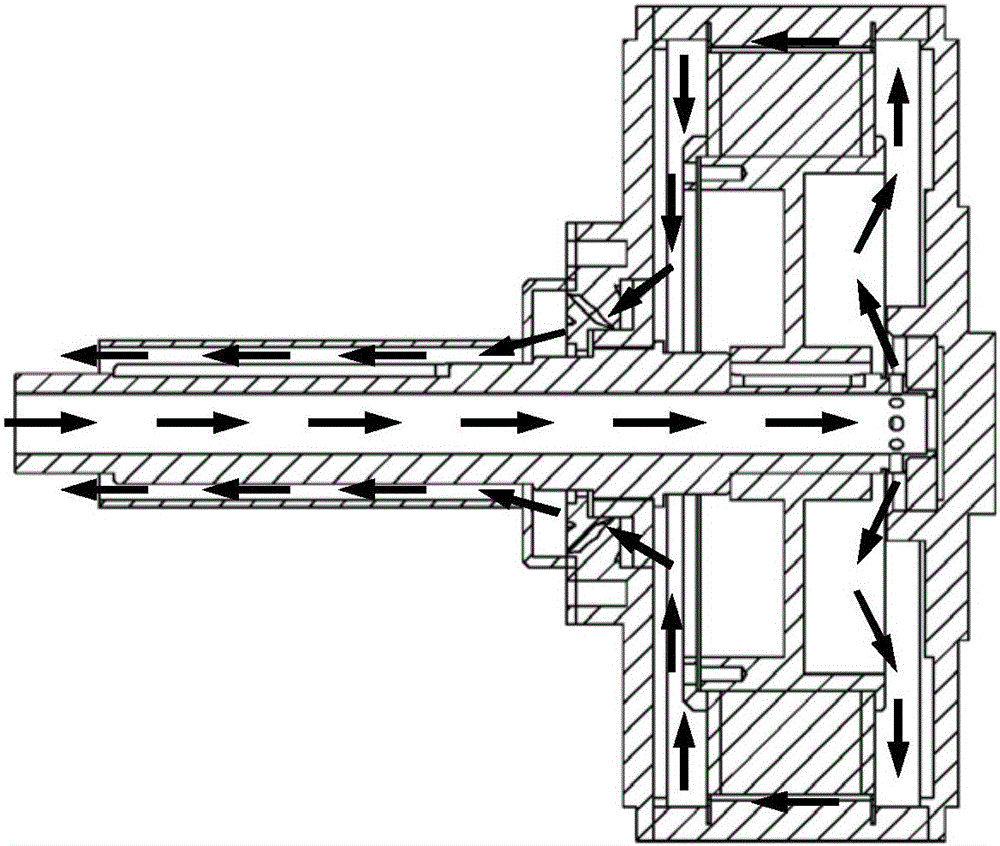

[0013] Such as figure 1 and figure 2 As shown, a waterproof and air-cooled heat dissipation structure of an electric vehicle hub motor includes an outer rotor 2 and an inner stator 1. The inner stator 1 is formed by stacking silicon steel sheets, and three-phase windings are embedded in the stator slots. The outer rotor 2 is arranged on the outer circumference side of the inner stator 1, and the inner side of the outer rotor 2 is uniformly embedded with permanent magnets. The inner stator 1 is installed on the motor shaft 4, and hub motor end covers 3 are arranged on both axial sides of the hub motor, including a left hub motor end cover and a right hub motor end cover, and the hub motor end cover 3 and The outer rotor 2 is fixed, a first bearing is provided between the motor shaft 4 and the end cover of the left hub motor, a second bearing is provided between the motor shaft and the end cover of the right hub motor, and the other end of the motor shaft is connected to the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com