Glass composition and electrode composition for solar cell using same

A technology of glass composition and electrode composition, which is applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve the problems of reduced fluidity of glass melt and reduced wettability of substrates, etc. , to achieve the effect of high fill factor, increased sintering temperature and time margin, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1 to 5

[0067] Glass compositions of Examples and Comparative Examples were prepared according to compositions and contents according to Table 1 and Table 2 below.

[0068] [Table 1]

[0069] Element

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

PbO(wt%)

46.9

37.43

44.97

59.26

47.71

65.96

TeO 2 (weight%)

49.0

58.83

54.29

36.5

50.4

30.85

Li 2 O (weight%)

4.1

3.74

0.74

4.24

1.89

3.19

total

100

100

100

100

100

100

Na 2 O (parts by weight)

-

2.67

-

3.7

1.78

1.59

K 2 O (parts by weight)

-

2.14

-

2.11

2.11

2.66

Bi 2 o 3 (parts by weight)

-

-

5.82

-

7.58

1.1

SiO 2 (parts by weight)

-

2.14

-

-

1.1

[0070] [Table 2]

[0071] Element

Embodiment 7 to 9 and comparative example 6 to 7

[0073] According to the composition and content according to the following Table 3 (unit: weight %), a conductive paste including conductive particles, glass frit, and a solvent in which a binder was dissolved was prepared.

[0074] In detail, each of the glass compositions was mixed with a vehicle (a binder and a solvent for dissolving the binder) using a PLM mixer, and then conductive particles (Ag) were added thereto, followed by secondary PLM mix. The respective pastes obtained by mixing were kneaded using a three-roll mill, and finally pastes for solar cell electrodes were prepared.

[0075] [table 3]

[0076]

experiment example 1

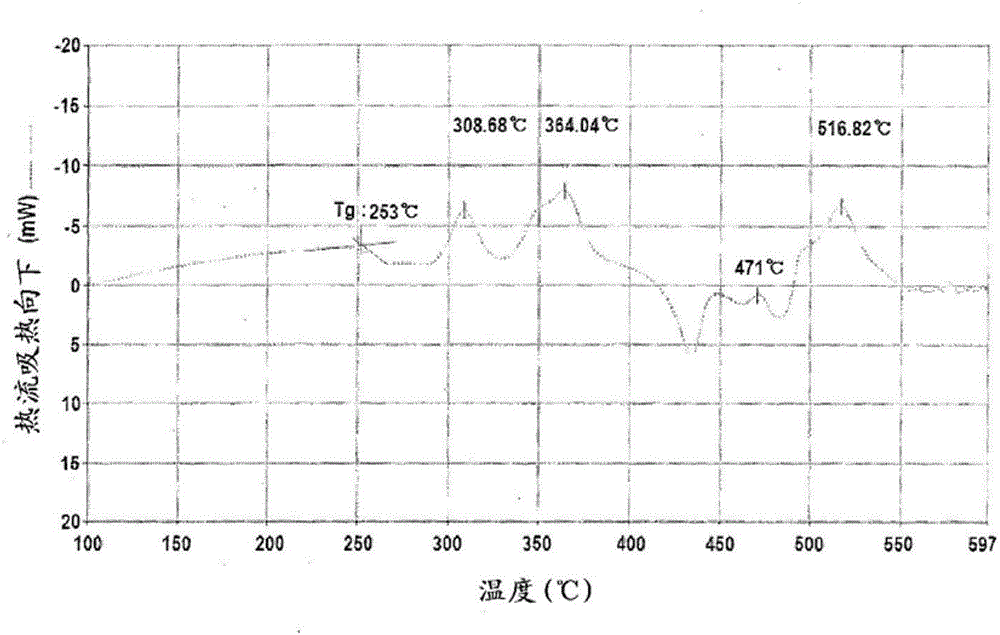

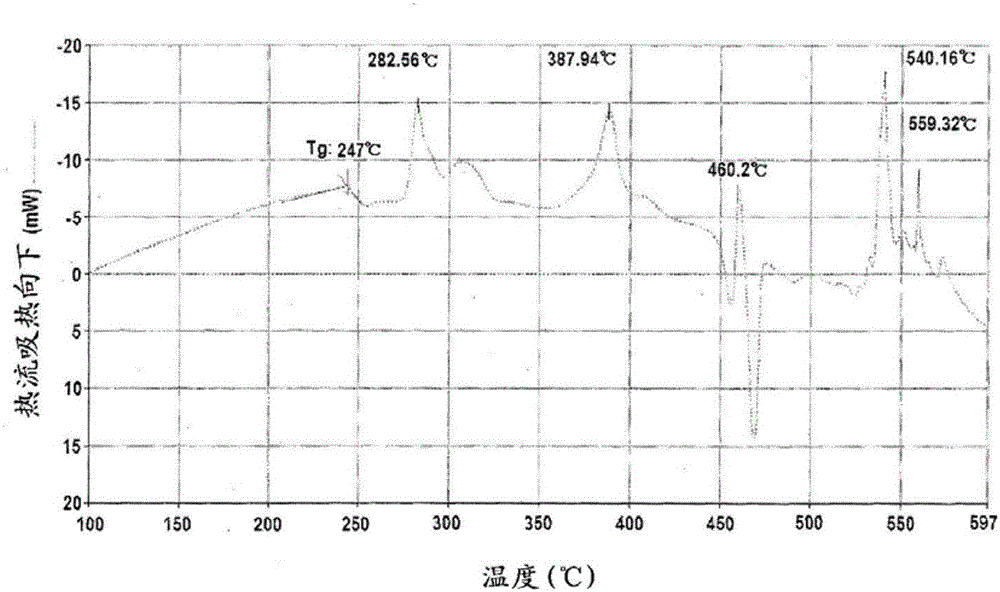

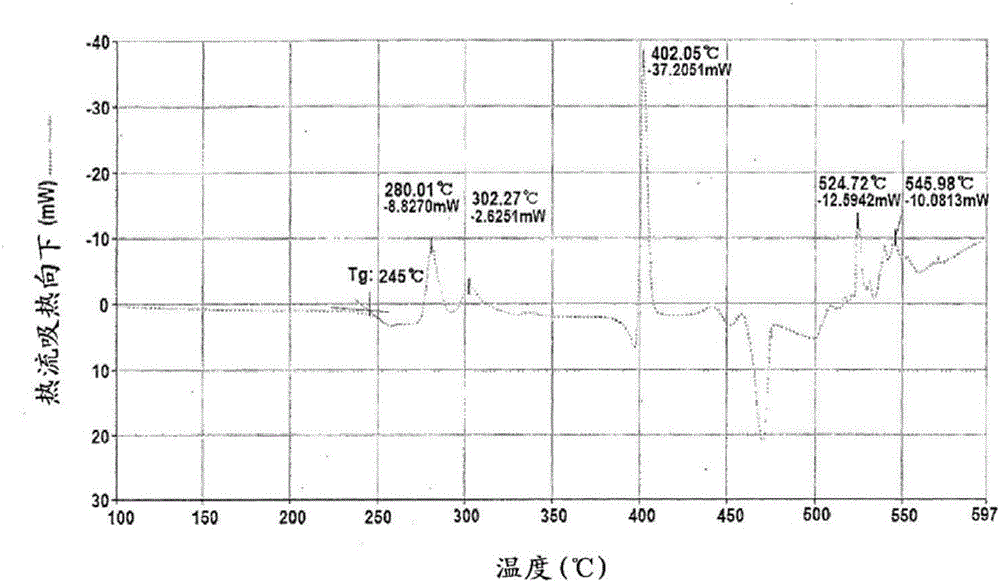

[0078] With respect to the glass compositions of Examples 1 to 3 and Comparative Examples 1 and 2, glass transition temperatures (Tg) and exothermic peaks were measured by differential scanning calorimetry (DSC). The results are given in Table 4. In addition, in Figure 1 to Figure 4 The differential scanning calorimetry results of Examples 1 to 3 and Comparative Example 1 are given in .

[0079] [Table 4]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com