Stubble cutting, ditching and earthing device for no-tillage planter of rice stubble

A seeder and stubble breaking technology, applied in agricultural machinery and implements, excavation/covering trenches, applications, etc., can solve problems such as unreliable soil covering, exposed seeds, and inability to close seed trenches, and achieve better soil removal effect. The effect of improving the quality of sowing and increasing the rate of seedling emergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

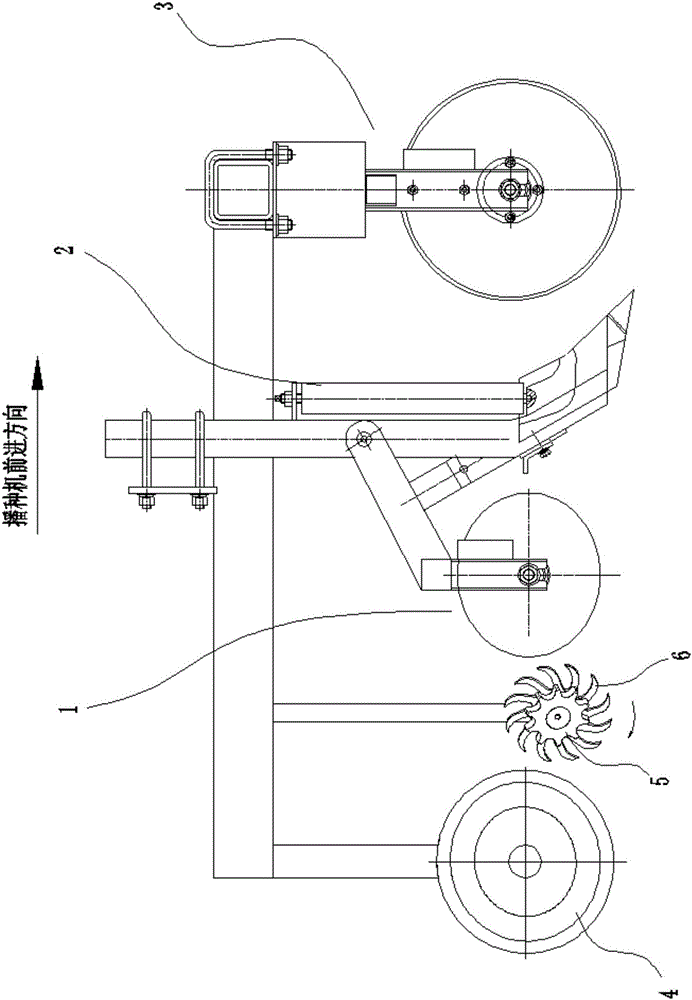

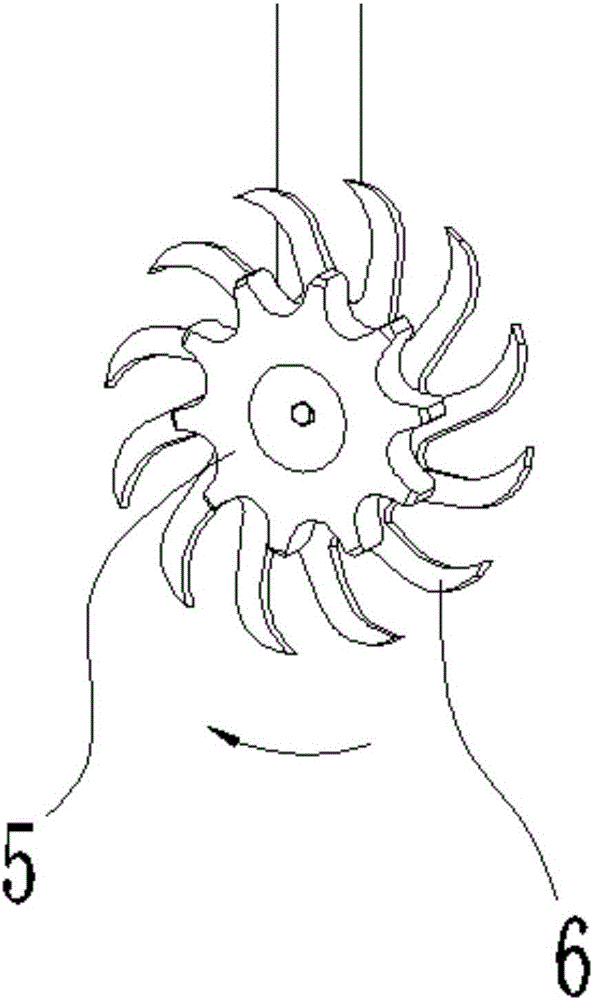

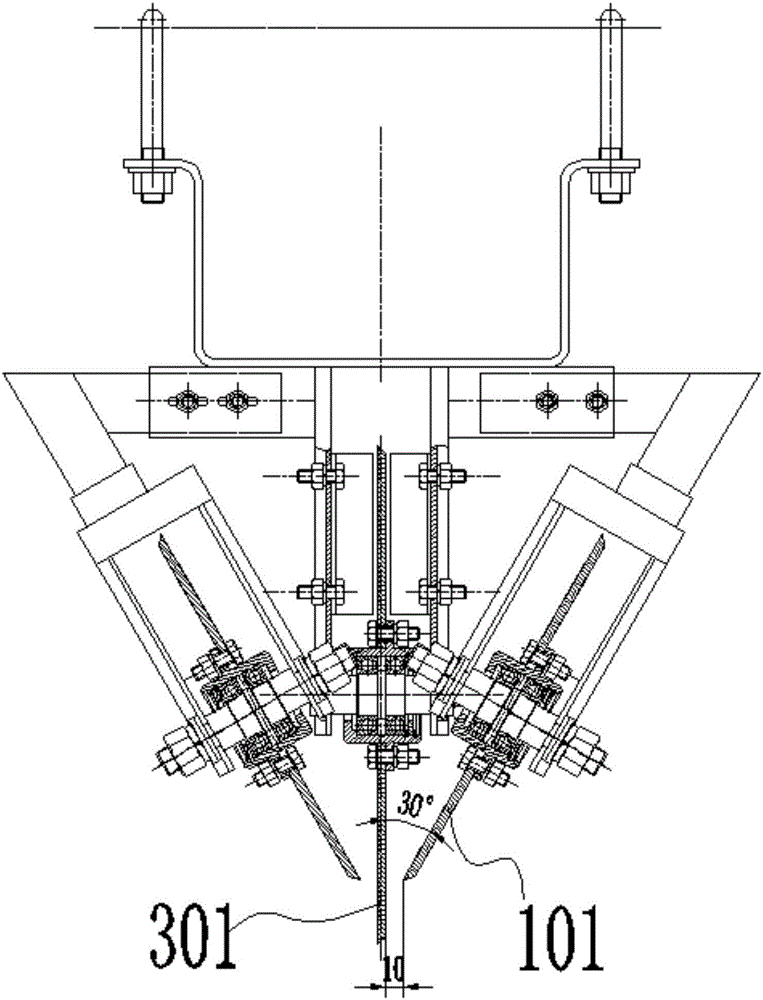

[0034] see Figure 1-Figure 10 , a stubble-breaking ditching and soil-covering device for a rice stubble no-tillage planter. The stubble-breaking ditching and soil-covering device is sequentially provided with a stubble breaking assembly 3, a ditch opener 2, and a ditch edge on the same straight line from front to back. Soil loosening part 1, soil parting part, pressing wheel part 4; Described stubble breaking assembly 3 comprises breaking stubble disc part 301, and described disc part 301 has sharp blade, can cut seam to land when rotating, and will Surface straw and weeds are cut off; the ditch opener 2 is used for ditching along the kerf; the ditch edge loosening part 1 includes a pair of top-to-bottom inwardly inclined, with the stubble-breaking disc part 301 as the The ditch edge loosening disc part 101 symmetrical on both sides of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com