Processing method of Lingyun Baekho white tea

A technology of Lingyun Pekoe tea and a processing method, applied in the processing field of Lingyun Pekoe white tea, can solve the problems of large difference in quality between batches, low aroma, slow dissolution, etc., and achieve high transparency, small difference between batches, and strong tea fragrance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

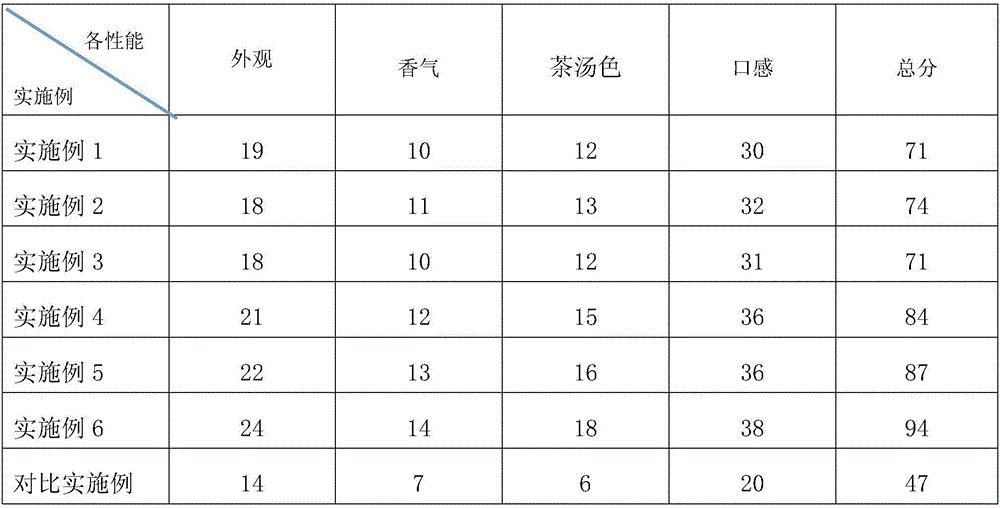

Examples

Embodiment 1

[0049] A processing method of Lingyun Baihaobai tea, comprising the following steps:

[0050] a. Picking: picking fresh leaves of Lingyun Pekoe tea with 1 bud and 1 leaf;

[0051] b. Withering for the first time: first spread the fresh leaves of Lingyun Pekoe tea in step a evenly in the withering tank, the thickness of which is based on the fact that the fresh leaves do not overlap, and then evenly spray the mixed enzyme preparation on the fresh tea leaves. The mixed enzyme preparation includes cellulase, 0.1% hemicellulase and 0.1% pectinase with a mass concentration of 0.2% respectively. The mixed enzyme preparation: Lingyun Baihao tea fresh leaf volume ratio is 1:12, and it is left for 30 minutes after spraying; Then put the withering tank in the ultrasonic environment of 45KHZ, ultrasonic for 20 minutes, and finally move the withering tank into the withering room for the first withering. The temperature of the withering room is controlled at 34°C and the humidity is 75%. ...

Embodiment 2

[0055] A processing method of Lingyun Baihaobai tea, comprising the following steps:

[0056] a. Picking: picking fresh leaves of Lingyun Pekoe tea with 1 bud and 2 leaves;

[0057] b. Withering for the first time: first spread the fresh leaves of Lingyun Pekoe tea in step a evenly in the withering tank, the thickness of which is based on the fact that the fresh leaves do not overlap, and then evenly spray the mixed enzyme preparation on the fresh tea leaves. The mixed enzyme preparation includes cellulase, 0.4% hemicellulase and 0.2% pectinase with a mass concentration of 0.5% respectively. The mixed enzyme preparation: Lingyun Baihao tea fresh leaf volume ratio is 1:14, and it is left for 20 minutes after spraying; Then place the withering tank in an ultrasonic environment of 70KHZ, ultrasonic for 15 minutes, and finally move the withering tank into the withering room for the first withering. The temperature of the withering room is controlled at 31°C and the humidity is 80%...

Embodiment 3

[0061] A processing method of Lingyun Baihaobai tea, comprising the following steps:

[0062] a. Picking: picking fresh leaves of Lingyun Pekoe tea with 1 bud and 3 leaves;

[0063] b. Withering for the first time: first spread the fresh leaves of Lingyun Pekoe tea in step a evenly in the withering tank, the thickness of which is based on the fact that the fresh leaves do not overlap, and then evenly spray the mixed enzyme preparation on the fresh tea leaves. The mixed enzyme preparation includes cellulase, 0.6% hemicellulase and 0.4% pectinase with a mass concentration of 0.8% respectively. The mixed enzyme preparation: Lingyun Baihao tea fresh leaf volume ratio is 1:18, and it is left for 10 minutes after spraying; Then place the withering tank in an ultrasonic environment of 100KHZ, ultrasonic for 5 minutes, and finally move the withering tank into the withering room for the first withering. The temperature of the withering room is controlled at 26°C and the humidity is 85%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com