Spraying arm assembly for dish-washing machine and dish-washing machine provided with spraying arm assembly

A spray arm assembly, dishwasher technology, applied in the direction of washing machine/washing machine for tableware, washing machine/rinsing machine parts for tableware, household appliances, etc., can solve the problem of poor washing, affecting the washing effect of dishwasher, washing Dead zone and other problems, to achieve the effect of good washing effect, simple structure, convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

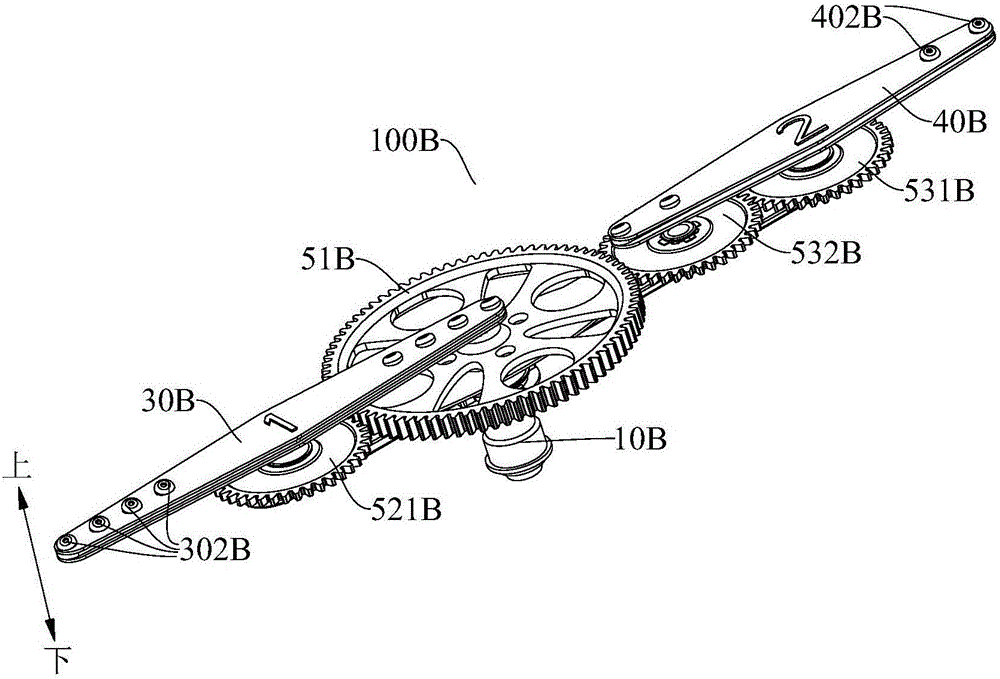

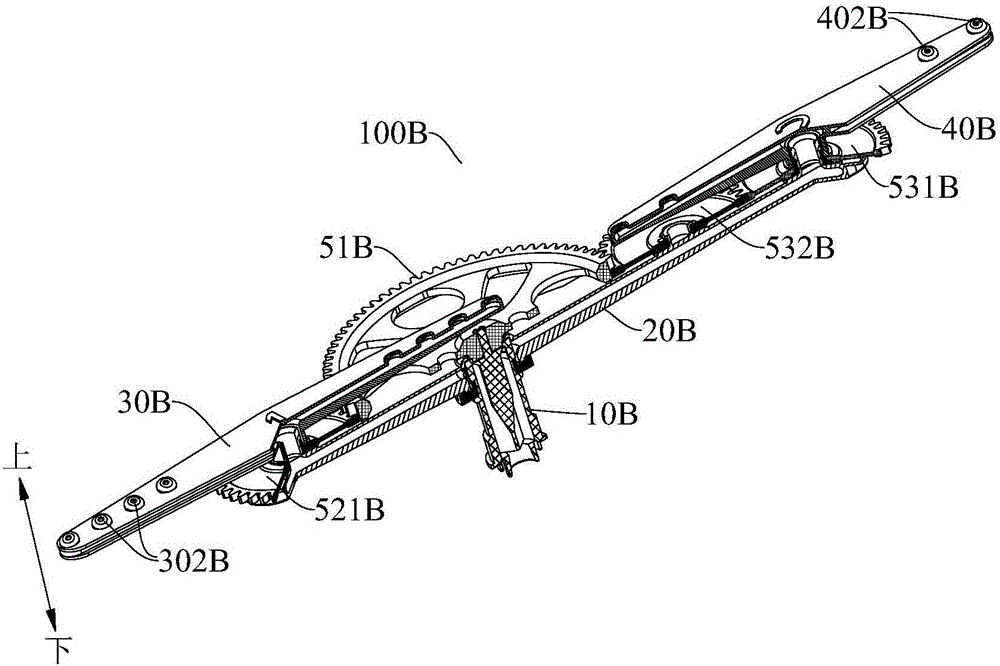

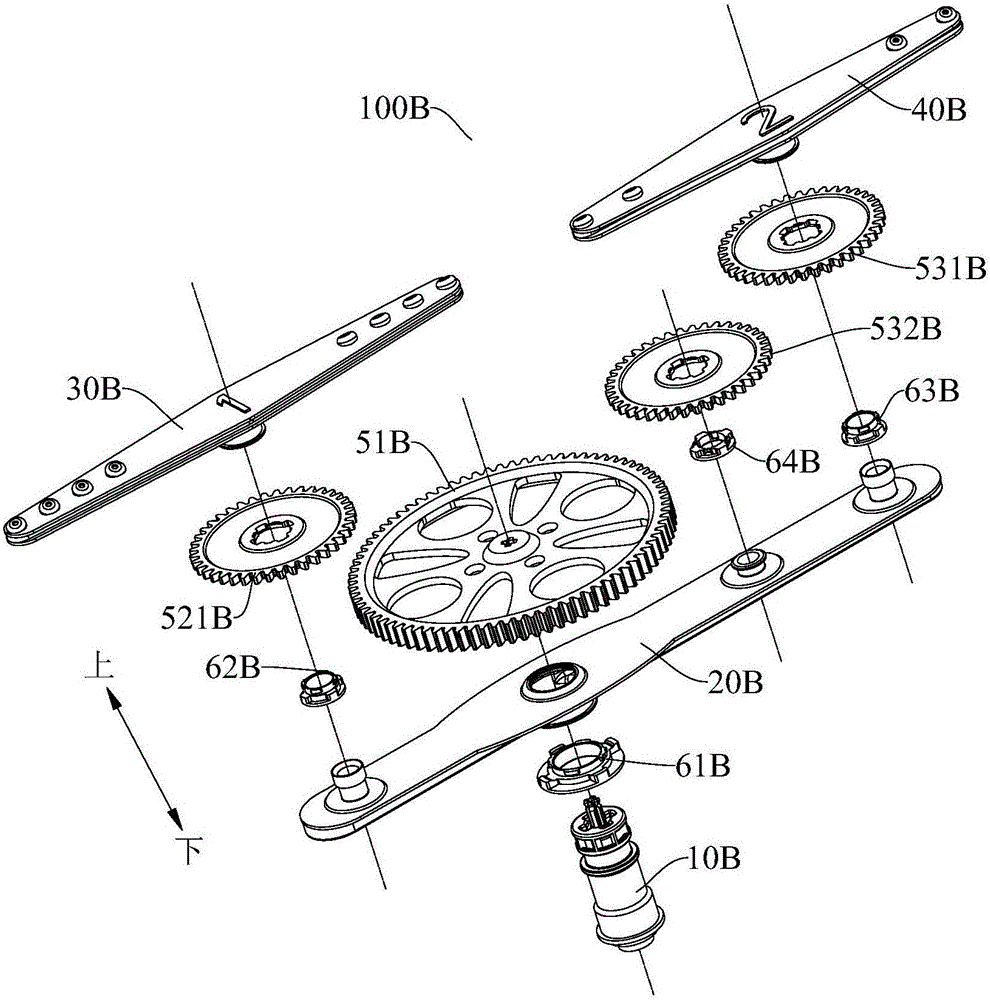

[0130] Such as Figure 1 to Figure 14 As shown, in this embodiment, the spray arm assembly 100B for the dishwasher is mainly composed of the spray arm seat 10B, the spray arm main body 20B, the first spray arm auxiliary body 30B, the second spray arm auxiliary body 40B, the first gear Group 52B, sun gear 51B, second gear group 53B, first slip ring 61B, second slip ring 62B, and third slip ring 63B.

[0131] Wherein, the first gear set 52B is a one-stage gear transmission, that is, the first gear set 52B includes a planetary gear, and the second gear set 53B is a two-stage gear transmission, that is, the second gear set 53B includes a second planetary gear 531B and is located at The second transmission gear 532B between the sun gear 51B and the second planetary gear 531B.

[0132] Such as figure 2 and Figure 4 As shown, the spray arm seat 10B is formed along the vertical direction (as figure 1 shown in the up and down direction), the spray arm seat 10B defines a water flo...

Embodiment 2

[0148] Figure 15 to Figure 28 As shown, in this embodiment, the spray arm assembly 100B for the dishwasher is mainly composed of the spray arm seat 10B, the spray arm main body 20B, the first spray arm auxiliary body 30B, the second spray arm auxiliary body 40B, the first gear Group 52B, sun gear 51B, second gear group 53B, first slip ring 61B, second slip ring 62B, and third slip ring 63B.

[0149] Wherein, the first gear set 52B is a three-stage gear transmission, that is, the first gear set 52B includes a first planetary gear 521B and two first transmission gears 522B, and the two first transmission gears 522B are arranged side by side on the first planetary gear 521B. Between the central gear 51B, and one of the two first transmission gears 522B is externally meshed with the other first transmission gear 522B and the first planetary gear 521B, and the other of the two first transmission gears 522B is connected to the center The gear 51B is externally meshed for transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com