Quartz breaking device

A crushing device and quartz stone technology, applied in the field of quartz stone crushing device and mixing device, can solve the problems of reduced work efficiency, complicated crushing process, long quartz stone crushing work, etc., and achieve the effect of simple operation and good crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

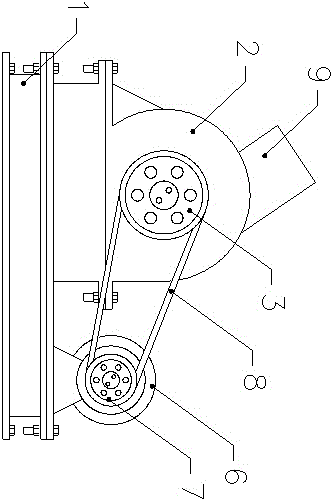

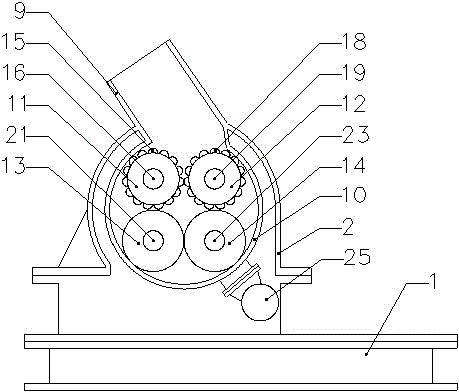

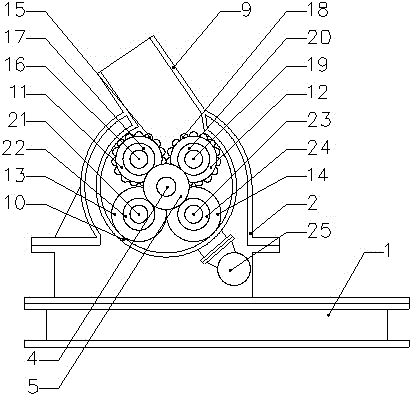

[0017] Such as Figure 1-3 As shown, a quartz stone crushing device includes a base 1, the left end of the upper side of the base 1 is provided with a gravel guard 2, and one side of the gravel guard 2 is provided with a large pulley 3. The large belt pulley 3 is connected with a rotating shaft 4, and one end of the rotating shaft 4 is connected with a driving gear 5; the base 1 on the right side of the gravel shield 2 is fixed with a drive motor 6, and the drive motor 6 The output shaft end of 6 is connected with a small pulley 7, and the outer circumference of the small pulley 7 is wound with a belt 8, and the belt 8 is bypassed by the large pulley 3; The feed port 9 is connected with a vibrating screen 10, and the vibrating screen 10 is provided with a roller shaft A11, a roller shaft B12, a roller shaft C13 and a roller shaft D14; the outer circumference of the roller shaft A11 is arranged with carbide protrusions A15, the roller shaft A11 is connected with the rotating s...

Embodiment 2

[0020] Such as Figure 1-3 As shown, a quartz stone crushing device includes a base 1, the left end of the upper side of the base 1 is provided with a gravel guard 2, and one side of the gravel guard 2 is provided with a large pulley 3. The large belt pulley 3 is connected with a rotating shaft 4, and one end of the rotating shaft 4 is connected with a driving gear 5; the base 1 on the right side of the gravel shield 2 is fixed with a drive motor 6, and the drive motor 6 The output shaft end of 6 is connected with a small pulley 7, and the outer circumference of the small pulley 7 is wound with a belt 8, and the belt 8 is bypassed by the large pulley 3; The feed port 9 is connected with a vibrating screen 10, and the vibrating screen 10 is provided with a roller shaft A11, a roller shaft B12, a roller shaft C13 and a roller shaft D14; the outer circumference of the roller shaft A11 is arranged with carbide protrusions A15, the roller shaft A11 is connected with the rotating s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap