Automatic cutting, forming and grinding device applied to bus auxiliary handrails

An automatic cutting and bus technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of increasing labor workload, wasting time, difficult to produce, etc., to achieve stable product quality, saving labor costs, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

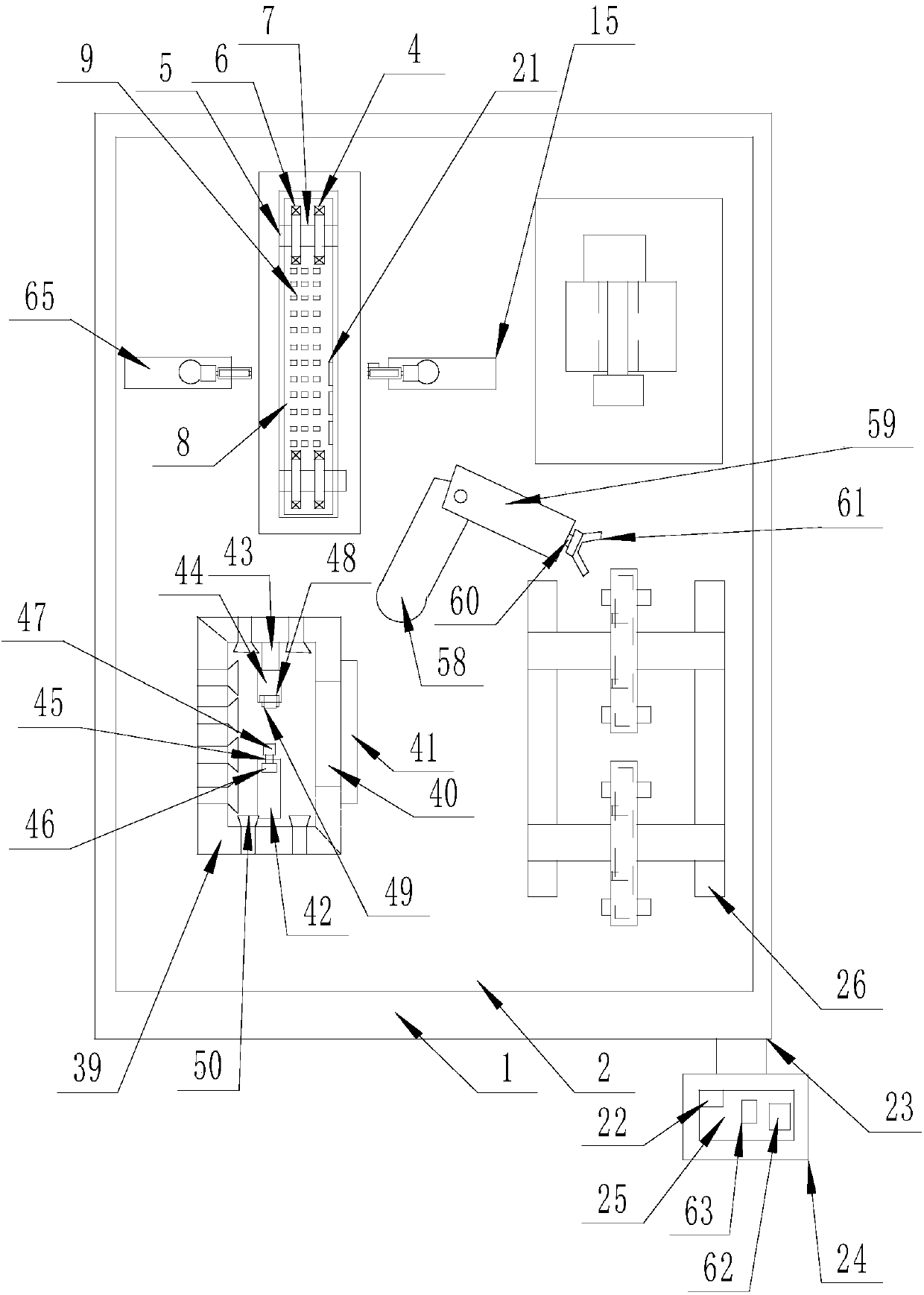

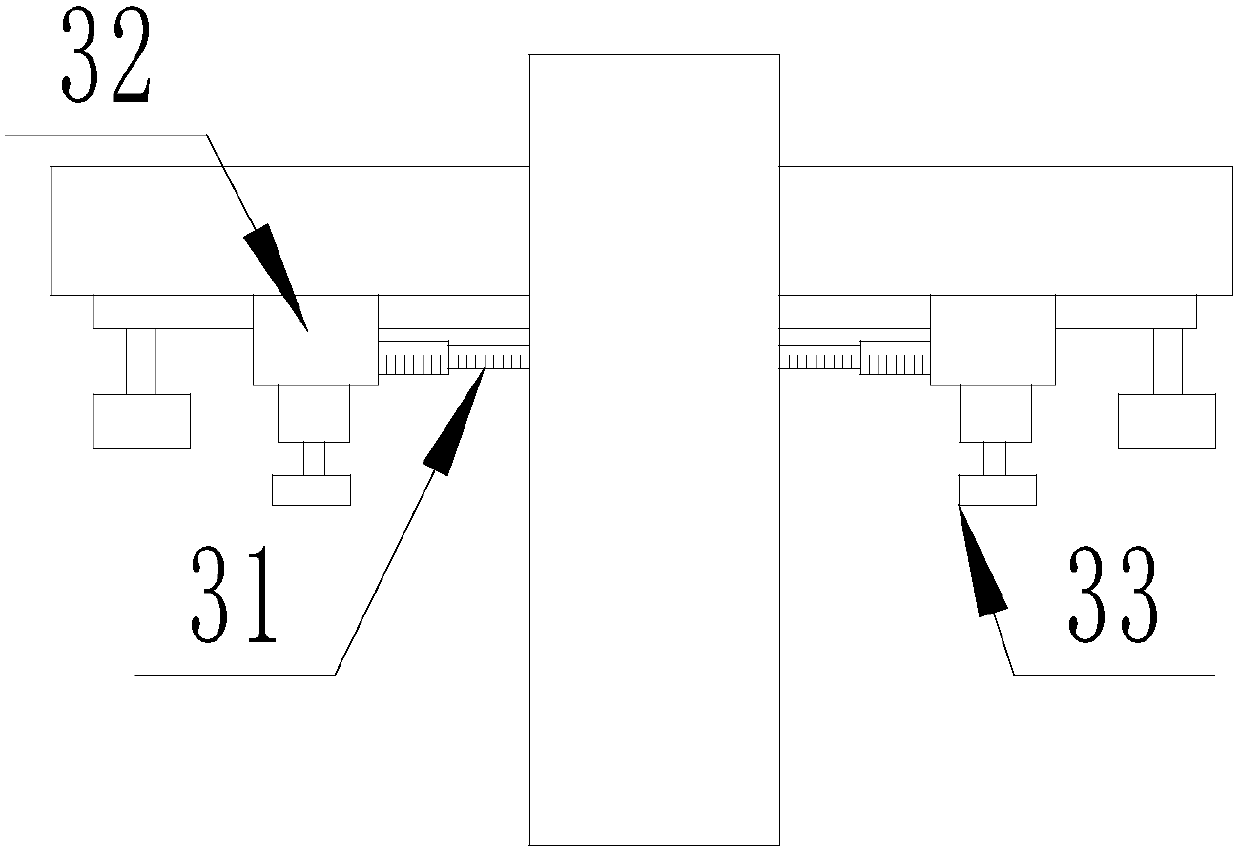

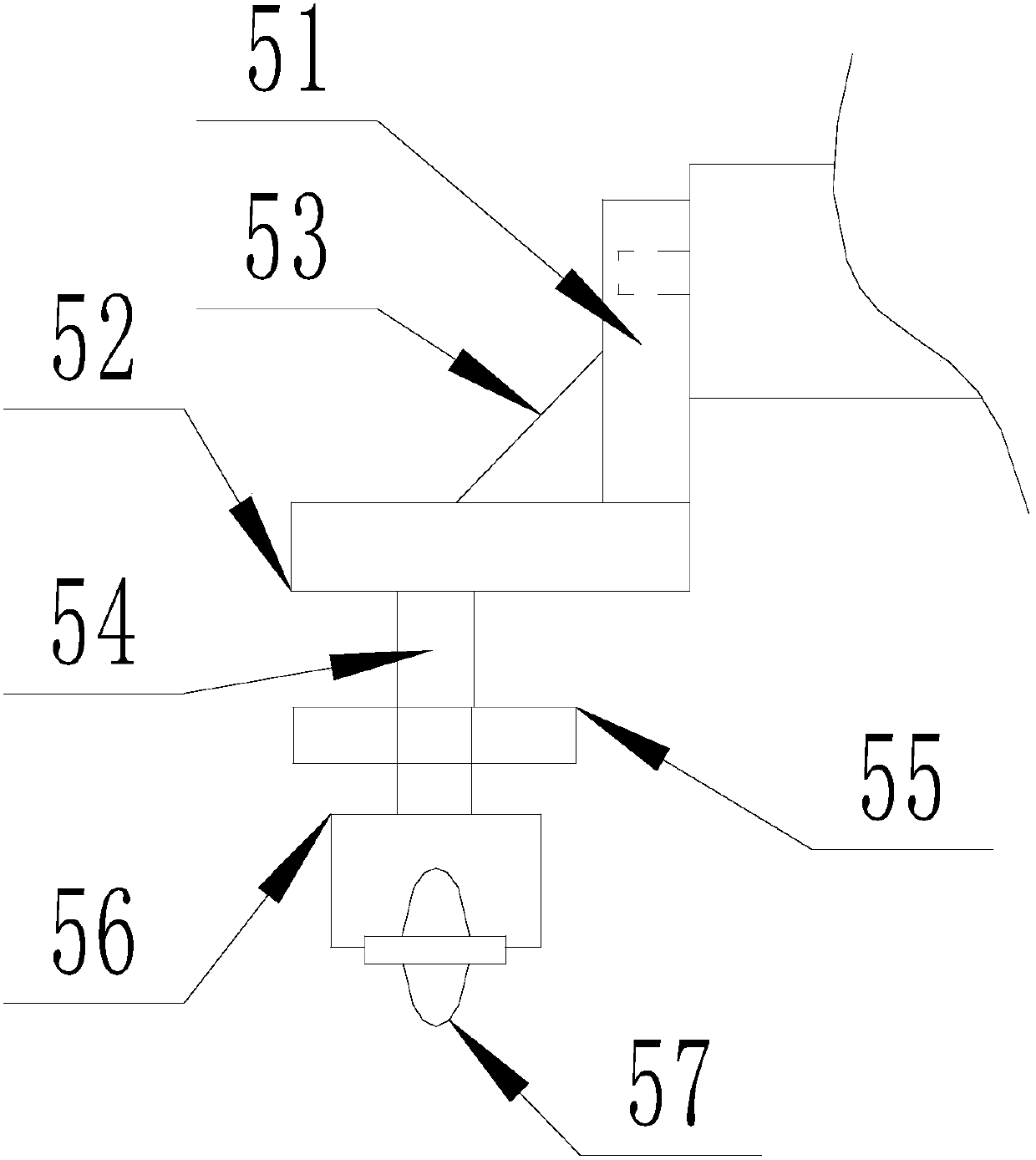

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown in the figure, an automatic cutting forming and grinding equipment for auxiliary railings of buses comprises a base (1), on which a workbench (2) is arranged, and the four corners of the side surface of the base (1) There is a folding walking mechanism at the center, and the workbench (2) is equipped with a precise cutting mechanism, a grinding mechanism, a painting mechanism, a clamping mechanism and an appearance forming mechanism. The precision cutting mechanism is located on the left side of the grinding mechanism, and the clip The taking mechanism is located at the rear side of the precision cutting mechanism and the grinding mechanism, the painting mechanism and the appearance forming mechanism are located at the rear side of the clamping mechanism, the painting mechanism is located on the left side of the appearance forming mechanism, and the appe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com